Slurry outlet device for fish ball machines with adjustable forming pressure

A technology of forming pressure and fishball machine, which is applied in the direction of measuring device, food forming, force/torque/work measuring instrument, etc., can solve the problems of inconsistency in the size of fishballs, the inconsistency of fishball size, and the inability to adjust the pulp output and feeding pressure separately For a long time and other problems, it achieves the effect of easy installation and subsequent cleaning and maintenance, excellent taste and appearance, and convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

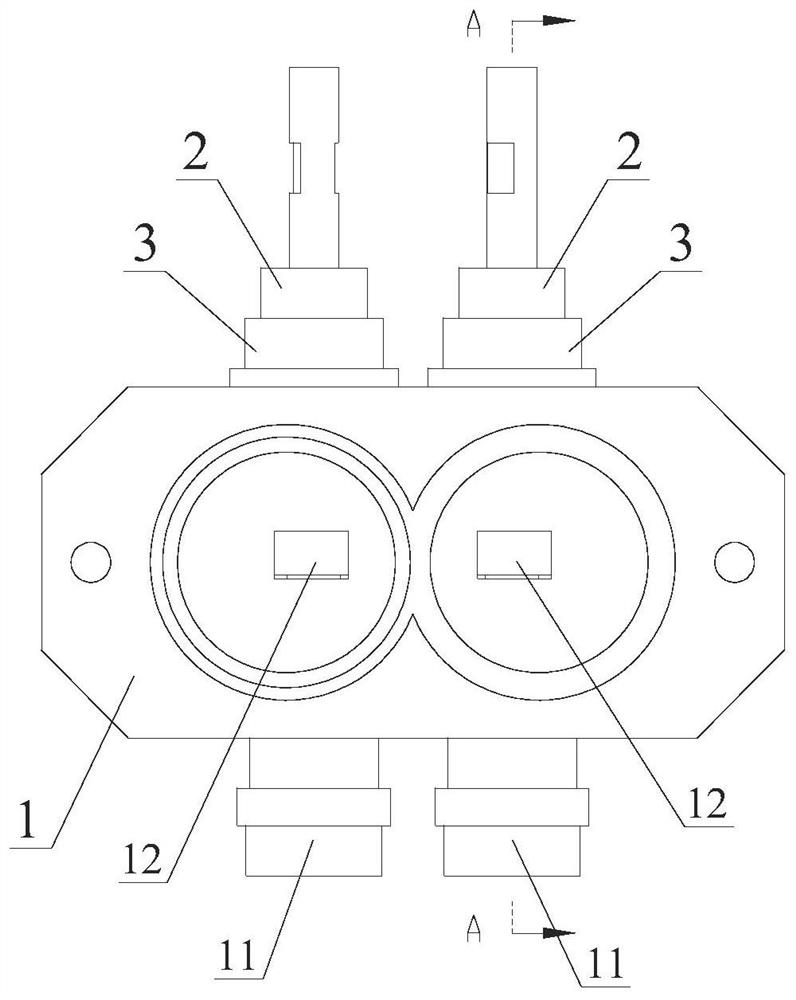

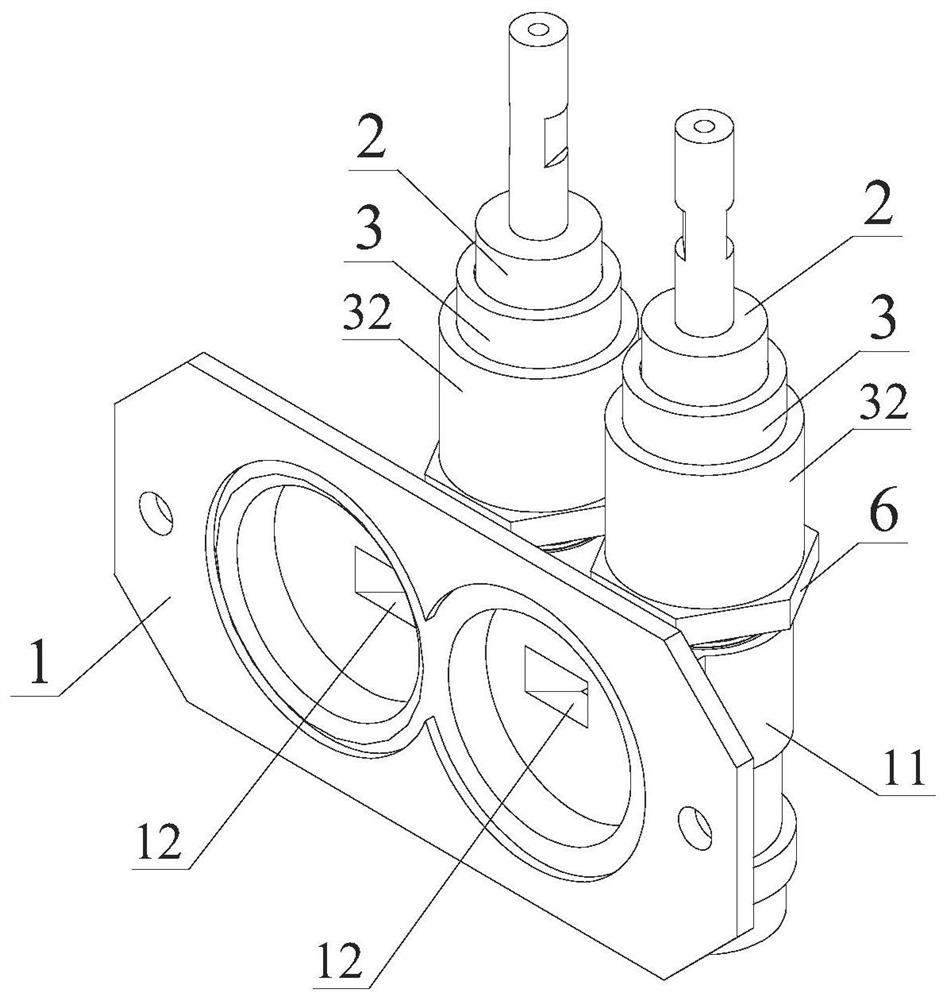

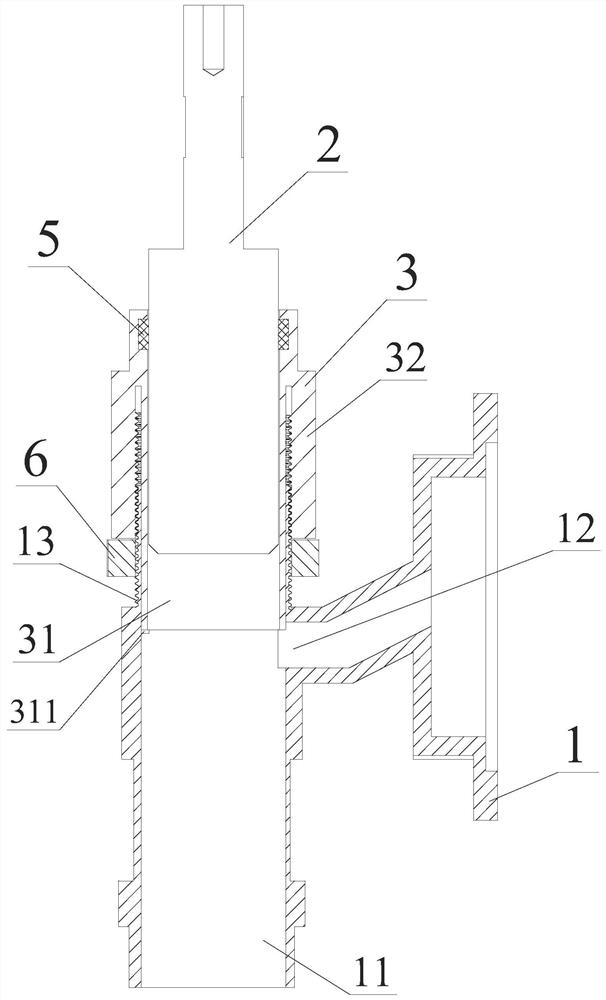

[0029] see Figure 1-6 As shown, a fishball machine pulping device with adjustable molding pressure includes a molding base 1 and a molding piston 2, and the molding base 1 is provided with at least two molding sleeves 11 and feed ports 12, each of which The forming piston 2 is respectively arranged in the forming sleeve 11, and the feeding port 12 is connected with the feeding device. It is characterized in that: each forming sleeve 11 is provided with an adjustment mechanism 3, and the adjustment mechanism 3 is provided with a pressure regulating ring 31 with one end extending into the forming sleeve 11, and the regulating mechanism 3 adjusts the telescopic length of the pressure regulating ring 31 in the forming sleeve 11 to adjust and control the feeding The size of the opening of the mouth 12, the forming piston 2 is coaxially sleeved in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com