Heterojunction cell texturing and washing method

A heterojunction cell and texturing technology, applied in the field of solar photovoltaic, can solve the problems of affecting the passivation effect, the HCl/HF pickling process cannot meet the technical requirements of cleanliness, and it is difficult to obtain good coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

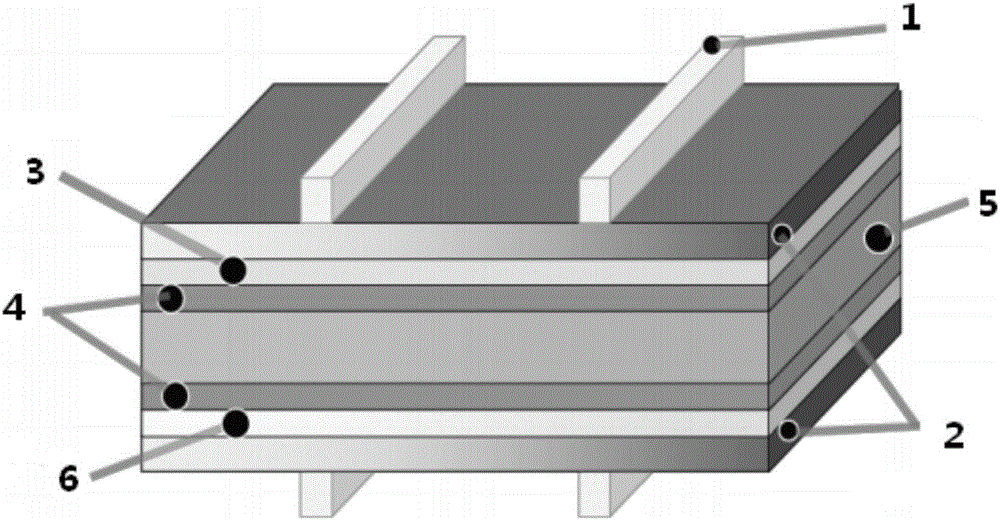

[0046] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

[0047] Refer to attached Figure 4 As shown, a texturing and cleaning method for a heterojunction battery comprises the following steps in sequence;

[0048] S1, cleaning the silicon wafer for the first time;

[0049] S2, performing damage removal treatment and texturing on the silicon wafer;

[0050] S3, cleaning the silicon wafer for the second time;

[0051] S4, using a mixed solution of hydrofluoric acid and nitric acid to treat the suede surface of the silicon wafer;

[0052] S5, cleaning the silicon wafer for the third time;

[0053] S6, pickling the silicon wafer;

[0054] S7, drying.

[0055] In step S1, the first cleaning is performed at 70-90° C. for 200-800 s using a mixture of ammonia water and hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com