Multifunctional microcapsule used for self-repairing of materials and preparation method thereof

A multifunctional microcapsule technology, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of lack of research and achieve the effect of simple preparation process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

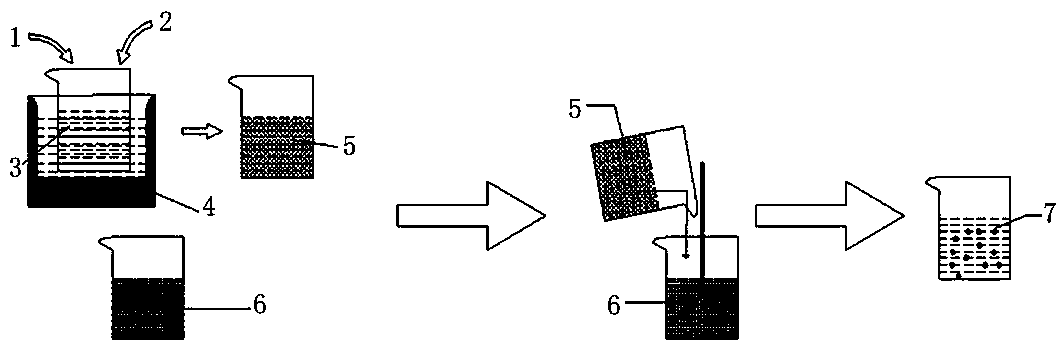

Method used

Image

Examples

Embodiment 1

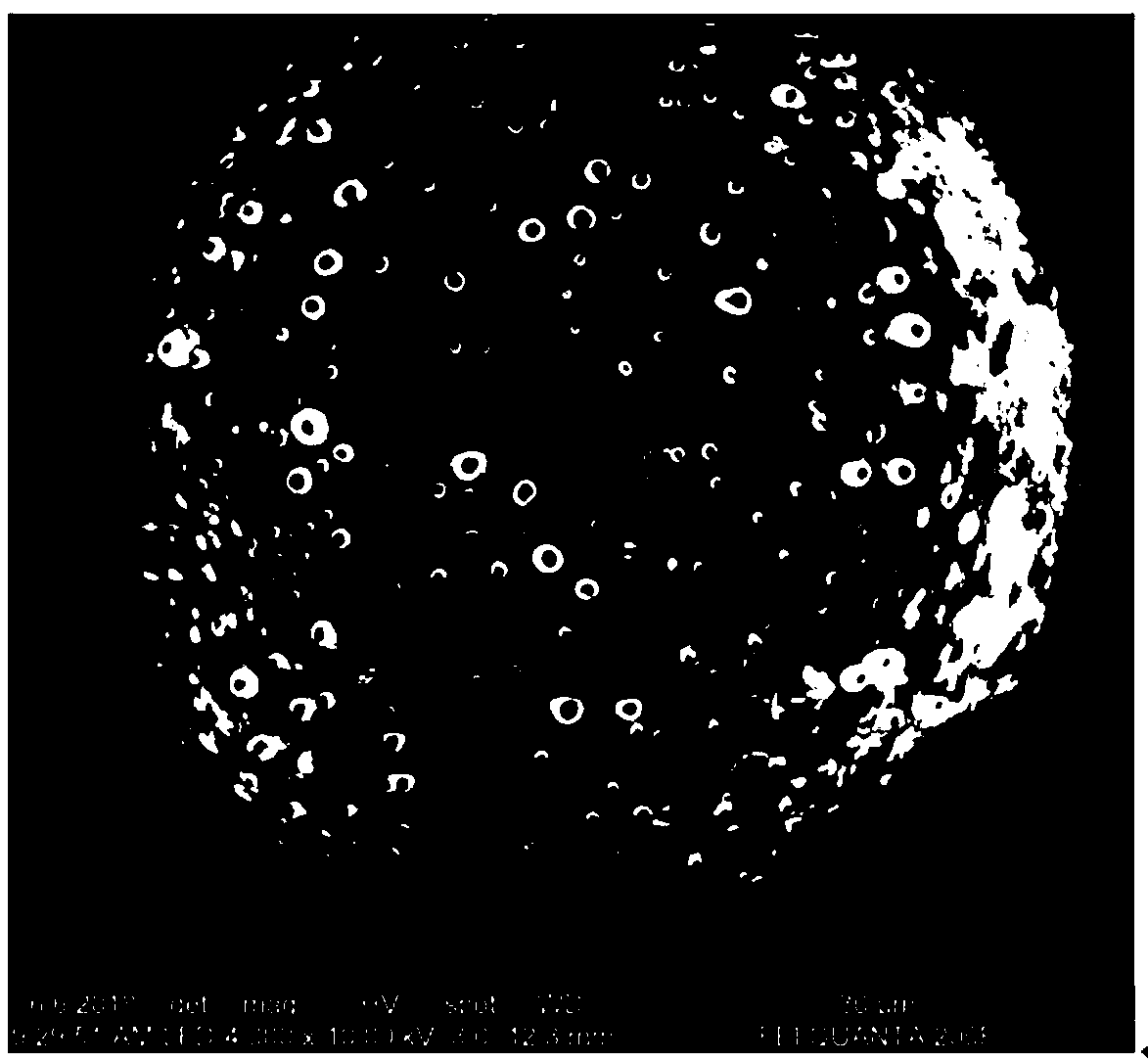

[0028] Ethyl cellulose with a viscosity of 20 was used as the wall material to prepare epoxy resin E-51 microcapsules.

[0029] Dissolve 25g of gelatin in 500g of deionized water to form a 5% gelatin solution as the water phase; then dissolve 5g of ethyl cellulose with a viscosity of 20 and 5g of epoxy resin E-51 in 60ml of dichloromethane, and ultrasonically dissolve to form a uniform The mixed solution is used as the oil phase; finally, use a rubber dropper to slowly add the oil phase to the water phase and stir at 800r / min to form an oil-in-water emulsion. After the mixed solution is added dropwise, continue stirring at a temperature of 30°C 5h, at this time the surface of the microcapsules is solidified, reduce the rotation speed modulation to 600r / min, and raise the temperature to 42°C and continue stirring for 2h, so that the solvent can be fully volatilized. Finally, wash with water and dry at room temperature to obtain microcapsules.

Embodiment 2

[0030] Example 2: Ethyl cellulose with a viscosity of 7 was used as the wall material to prepare epoxy resin E-51 microcapsules.

[0031] Dissolve 25g of gelatin in 500g of deionized water to form a 5% gelatin solution as the water phase; then dissolve 5g of ethyl cellulose with a viscosity of 7 and 5g of epoxy resin E-51 in 60ml of dichloromethane, and ultrasonically dissolve to form a uniform The mixed solution is used as the oil phase; finally, use a rubber dropper to slowly add the oil phase to the water phase and stir at 900r / min to form an oil-in-water emulsion. After the mixed solution is added dropwise, continue stirring at a temperature of 30°C 5h, at this time the surface of the microcapsules is solidified, reduce the rotation speed modulation to 600r / min, and raise the temperature to 42°C and continue stirring for 2h, so that the solvent can be fully volatilized. Finally, wash with water and dry at room temperature to obtain microcapsules.

Embodiment 3

[0032] Example 3: Epoxy resin E-51 microcapsules were prepared by using ethyl cellulose with a viscosity of 14 as the wall material.

[0033] Dissolve 25g of gelatin in 500g of deionized water to form a gelatin solution with a concentration of 5% as the water phase; then dissolve 5g of ethylcellulose with a viscosity of 14 and 5g of epoxy resin E-51 in 60ml of dichloromethane, and ultrasonically dissolve to form a uniform The mixed solution is used as the oil phase; finally, slowly drop the oil phase into the water phase with a rubber dropper and stir at 1000r / min to form an oil-in-water emulsion. After the mixed solution is added dropwise, continue stirring at a temperature of 30°C 5h, at this time the surface of the microcapsules is solidified, reduce the rotation speed modulation to 600r / min, and raise the temperature to 42°C and continue stirring for 2h, so that the solvent can be fully volatilized. Finally, wash with water and dry at room temperature to obtain microcapsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com