Local resin curing construction process for reconstruction and extension of drainage pipe network

A technology of resin curing and drainage pipe network, applied in the direction of pipe components, chemical instruments and methods, pipes/pipe joints/pipe fittings, etc., can solve the problems affecting the daily travel safety of the people, lack of experience in system management, and traffic disorder, etc. To achieve the effect of shortening the construction period, increasing the strength of the pipeline and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

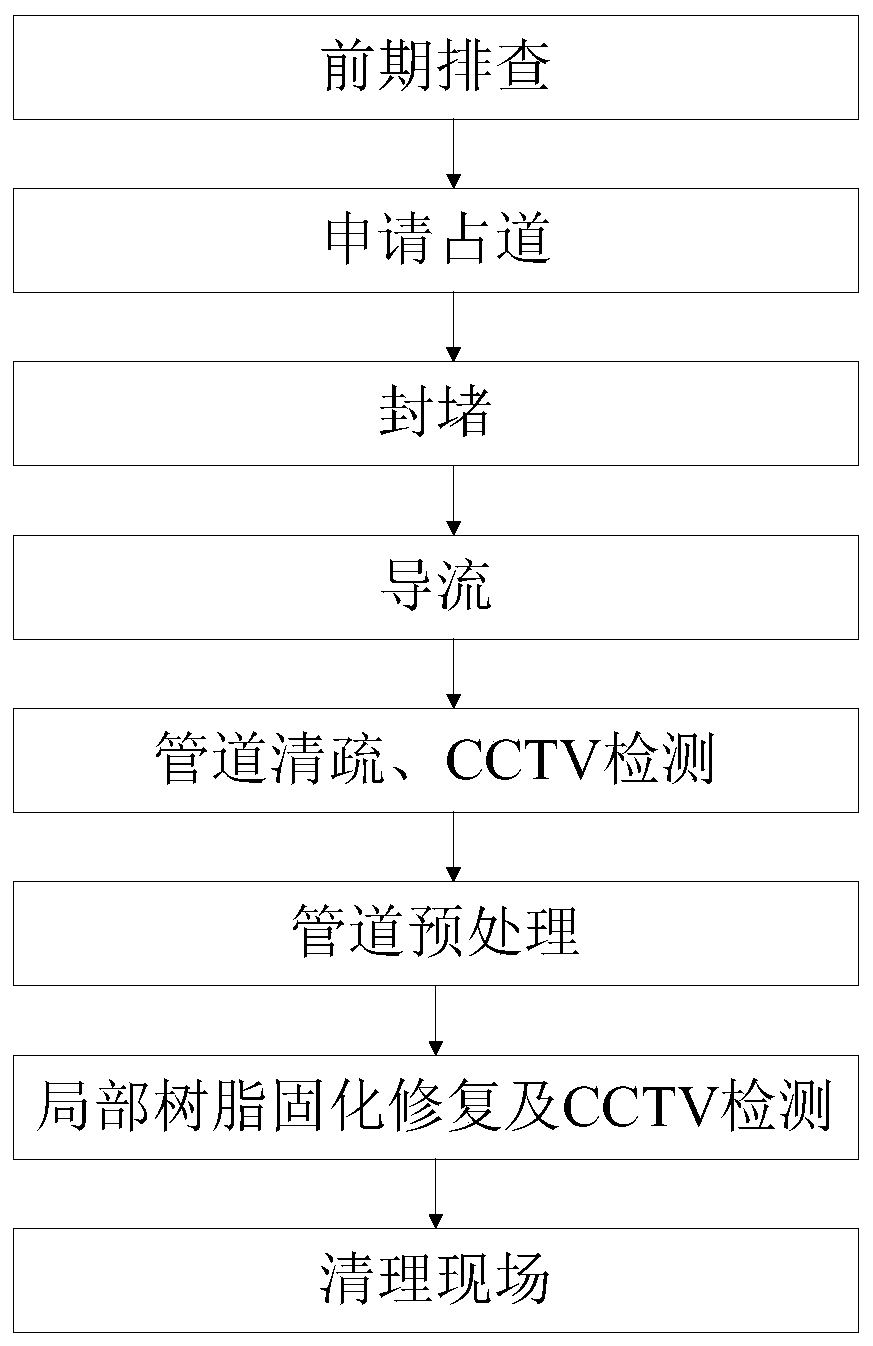

[0029] figure 1 It is a flow chart of an embodiment of a partial resin curing construction process for the reconstruction and expansion of a drainage pipe network according to the present invention. As shown in the figure, the present invention provides a partial resin curing construction process for the reconstruction and expansion of a drainage pipe network, which includes the following steps:

[0030] (1) Preliminary investigation: Conduct CCTV inspection or QV inspection for those without inspection data in the early stage to judge the defects of the pipe section, and use CCTV to inspect and review the internal conditions of the pipeline before repairing.

[0031] (2) Apply for road occupation: According to the design drawings and site survey results, report the corresponding road occupation and structures to be demolished to the supervisor and construction unit.

[0032] (3) Sealing: During the repairing construction of the pipe section, the pipeline is safely blocked, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com