Heavy Duty Flexible Support Device

A flexible support and heavy load technology, applied in the field of lithography machines, can solve problems such as damage, shorten the service life, and fatigue of flexible mechanisms, and achieve the effects of avoiding resonance, reducing short-term imaging errors, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

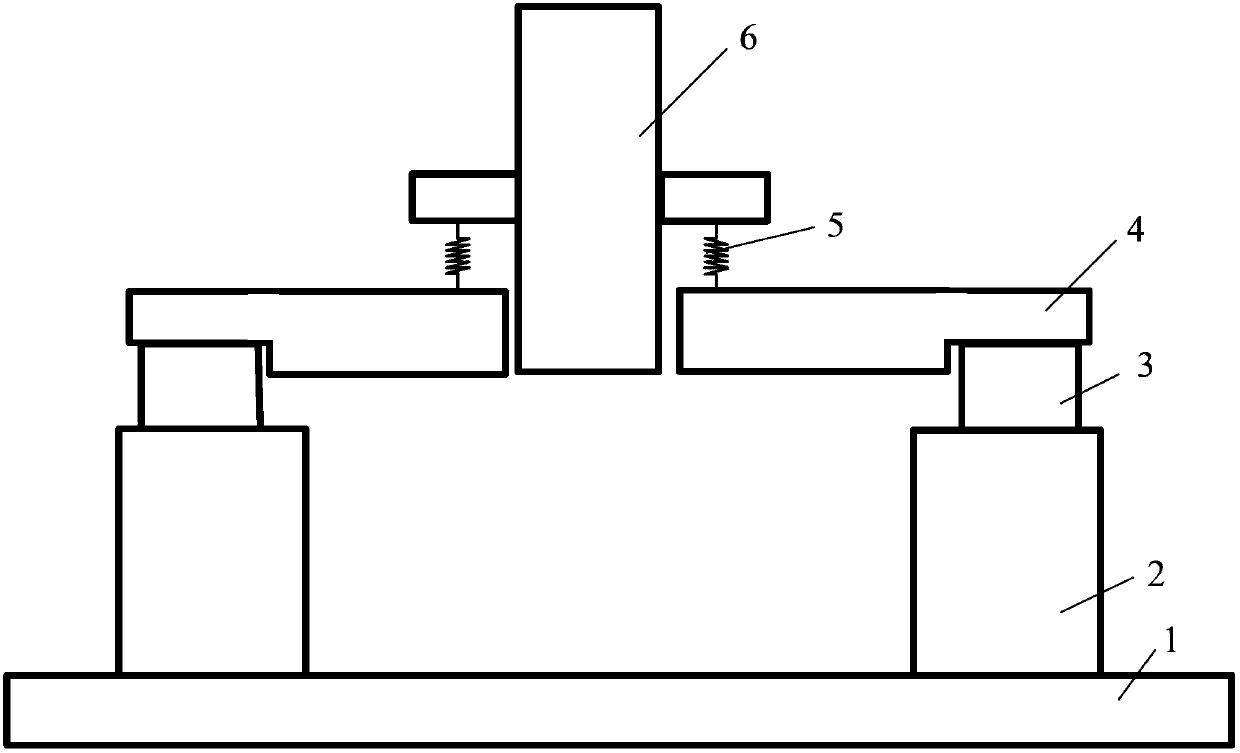

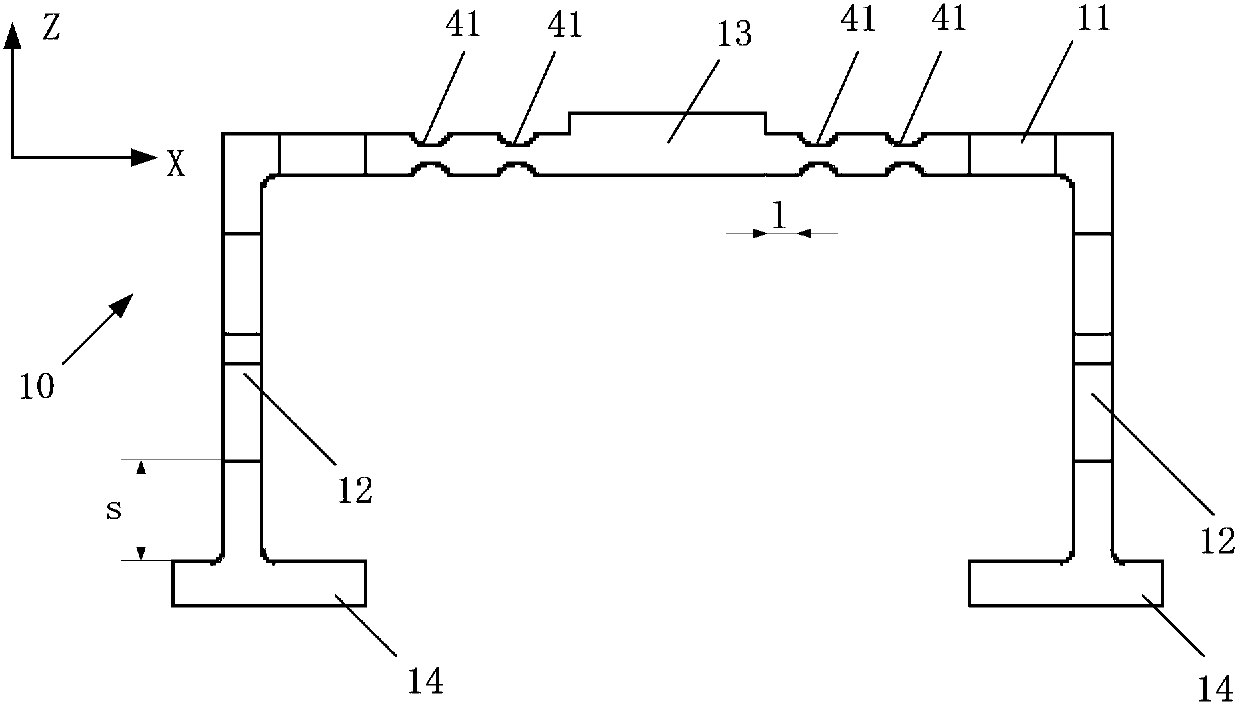

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

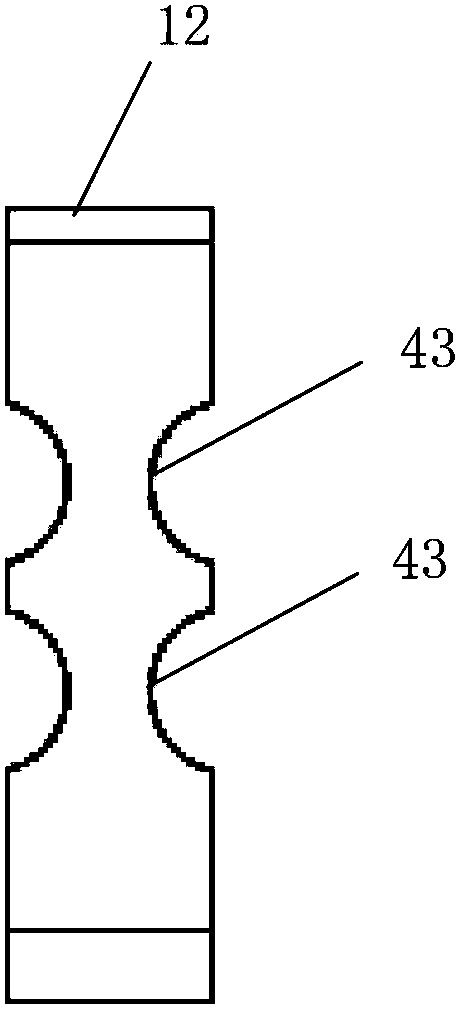

[0032] Please refer to Figure 2-5 , and combined with Figure 7a , the heavy-duty flexible support device of the present invention includes three groups of flexible mechanisms 10, the three groups of flexible mechanisms 10 support the objective lens 20, and are arranged in an isosceles triangle on the main substrate 30 of the photolithography machine. The flexible mechanism 10 comprises: a top crossbeam 11 and two side vertical beams 12, the two ends of the top crossbeam 11 are respectively connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com