A coil terminal conductive sheet structure

A technology of conductive sheet and terminal, which is applied in the field of coil terminal conductive sheet structure, can solve the problems of affecting production efficiency, troublesome winding, low production efficiency, etc., and achieve the effect of convenient tin dipping process and convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the drawings and specific embodiments.

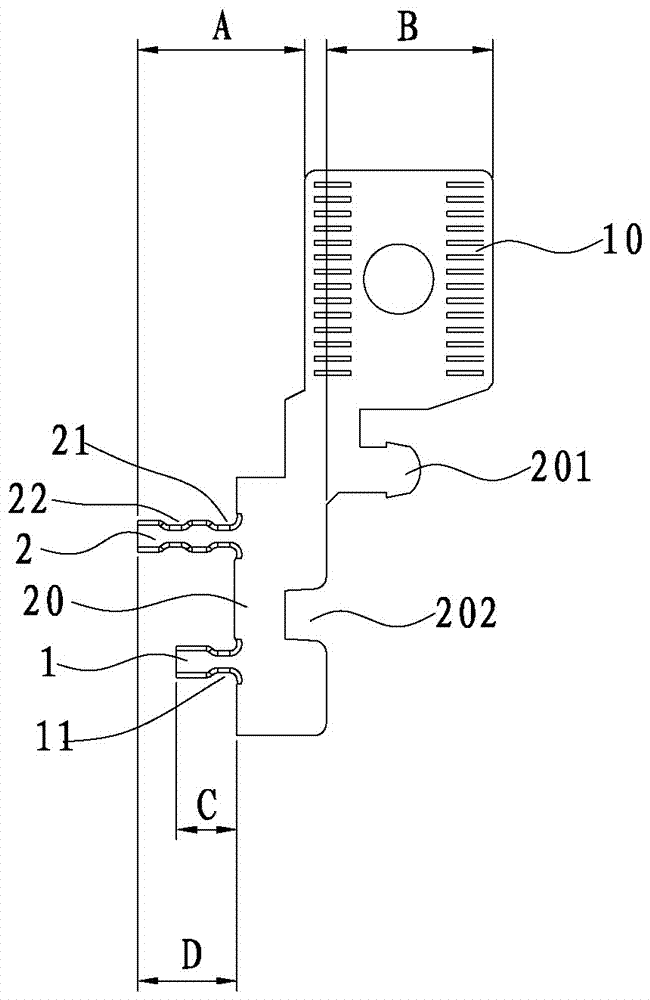

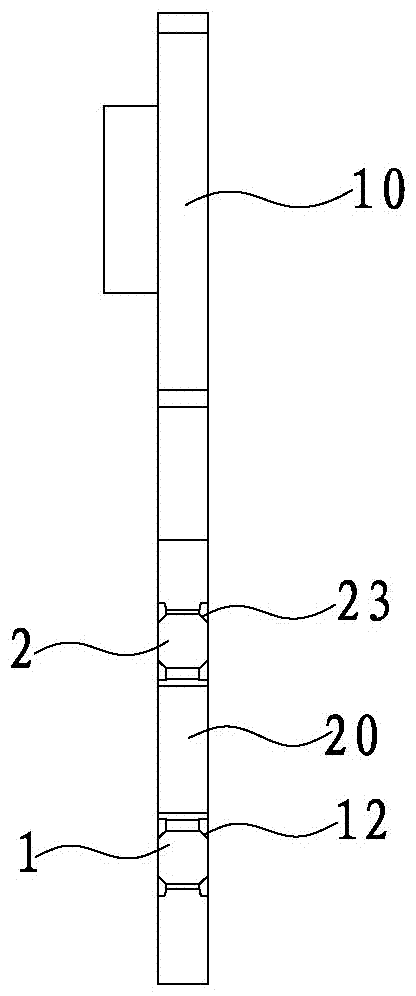

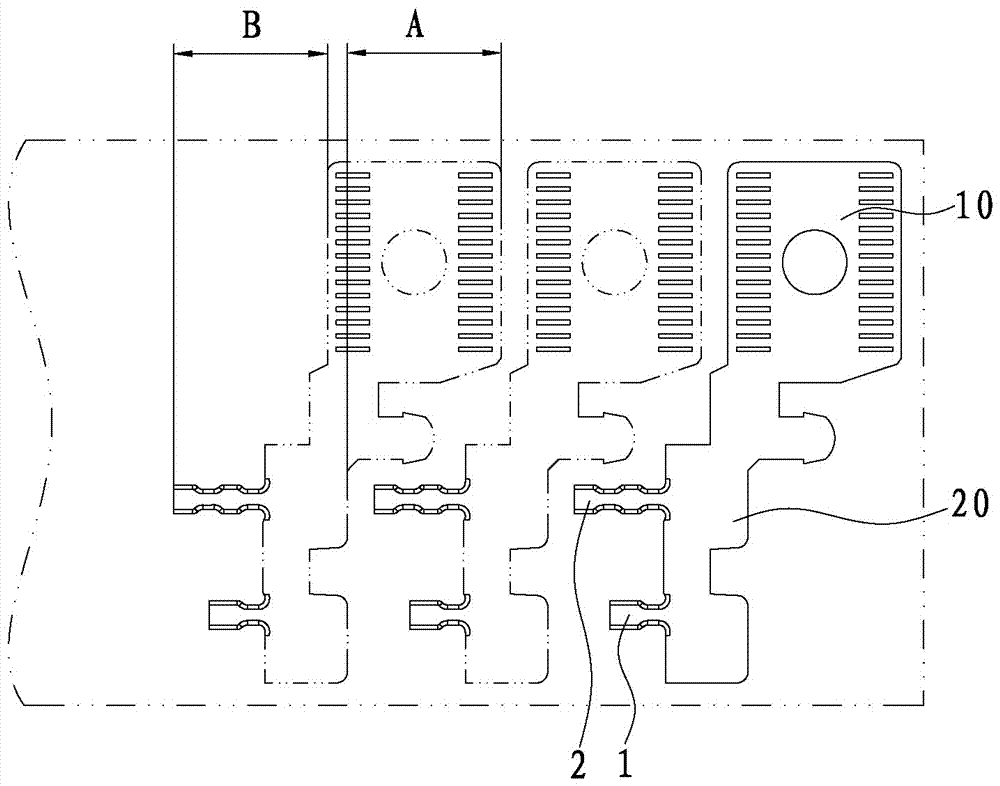

[0038] Refer to Figure 1 to Figure 7 As shown, a coil terminal conductive sheet structure is composed of a contact part 10 and a mounting part 20 integrally formed. A first terminal 1 and a second terminal 2 are formed at intervals between the mounting part 20. The height of the first terminal 1 is smaller than The height of the second terminal 2 is that the second terminal 2 is close to the contact portion 10, and the coil winding wire is first wound on the first terminal 1 and then fixed on the second terminal 2.

[0039] Since the height of the first terminal 1 is smaller than the height of the second terminal 2, there is no block when winding, and the winding is more convenient; the winding of the first terminal 1 can play a pre-tightening effect, so that the first terminal 1 and The winding of the second terminal 2 is in a relatively loose state, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com