Angular high-voltage plug

A high-voltage plug, angled technology, applied in the connection of permanent deformation, two-part connection device, electrical components, etc., can solve the problem that the connector system can no longer be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

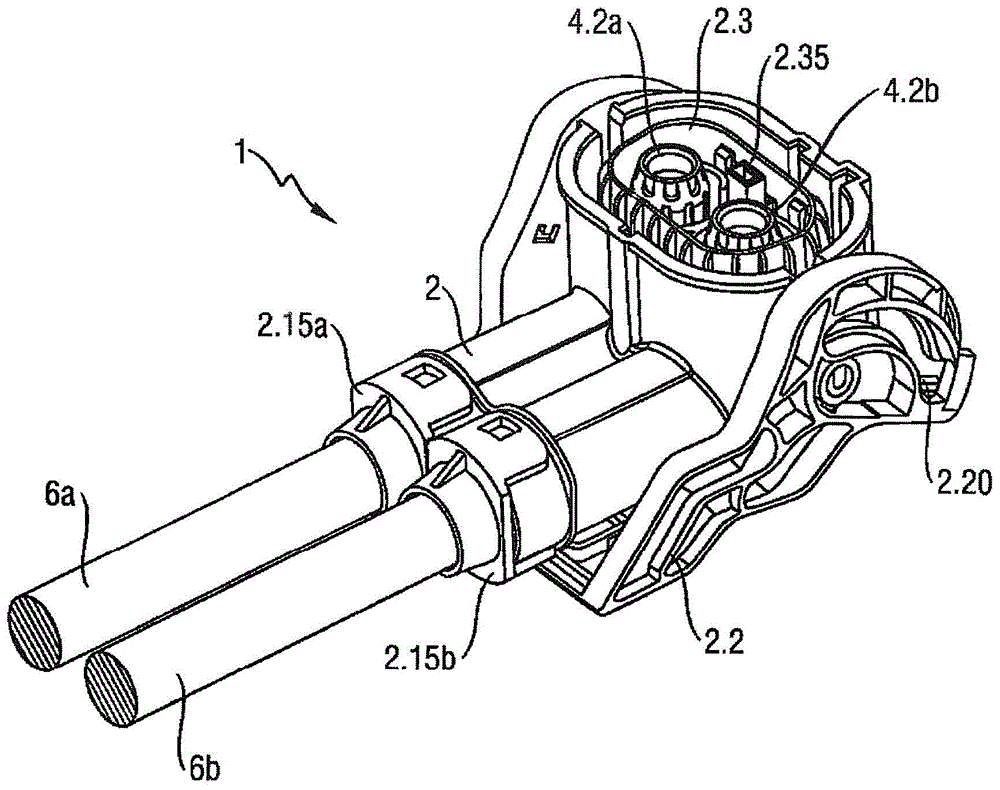

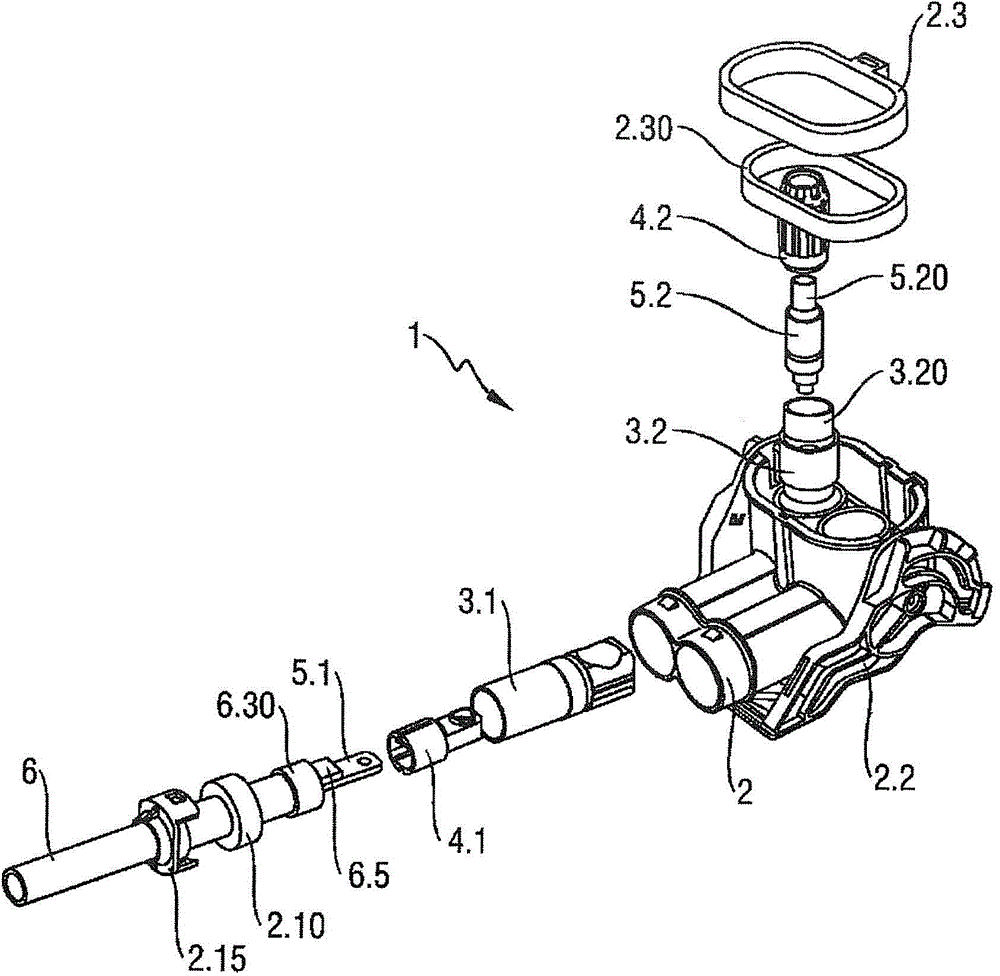

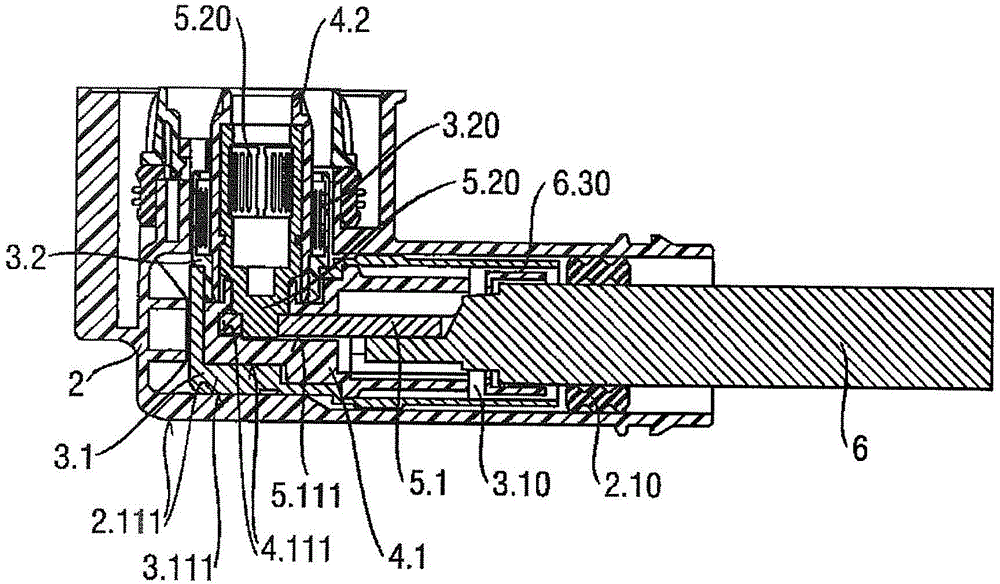

[0072] figure 1An angled high voltage plug 1 according to the invention is shown. The angled high-voltage plug 1 according to the invention is designed as a double plug and is connected accordingly to the two conductors 6a, 6b of the on-board power supply of the motor vehicle. On the conductor side, the housing 2 of the plug 1 is closed with two covers 2.15a, 2.15b. The cover parts 2.15a, 2.15b can be snapped onto the housing 2 and at the same time the cover parts 2.15a, 2.15b are respectively positioned with a seal (not shown) in order to prevent media from entering the corresponding connection point of the plug and one of the conductors infiltrate. A locking bracket 2.2 is fastened to the housing 2, which should in particular facilitate the assembly of the angled high-voltage plug 1 in a correspondingly configured (not shown) plug receptacle. The illustrated locking bow 2.2 additionally has a part of a latching part 2.20, by means of which part of the latching part 2.20 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com