Hook type peanut harvester

A peanut harvester and hook-type technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., to achieve the effects of saving harvesting costs, reducing energy consumption, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

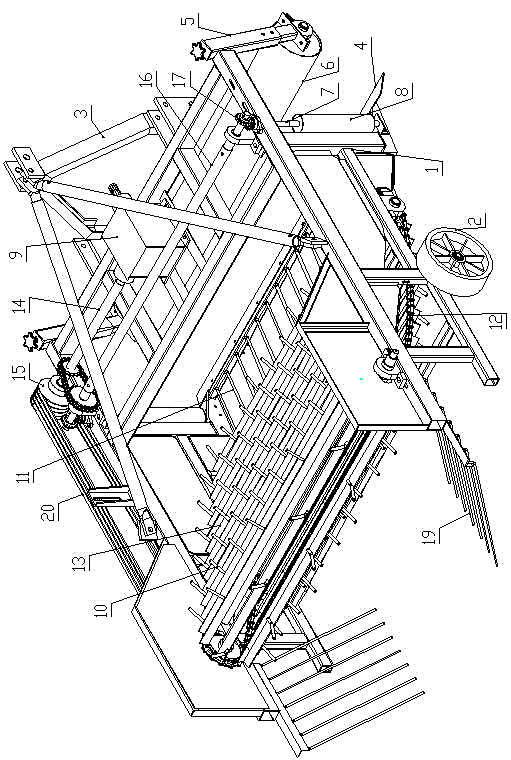

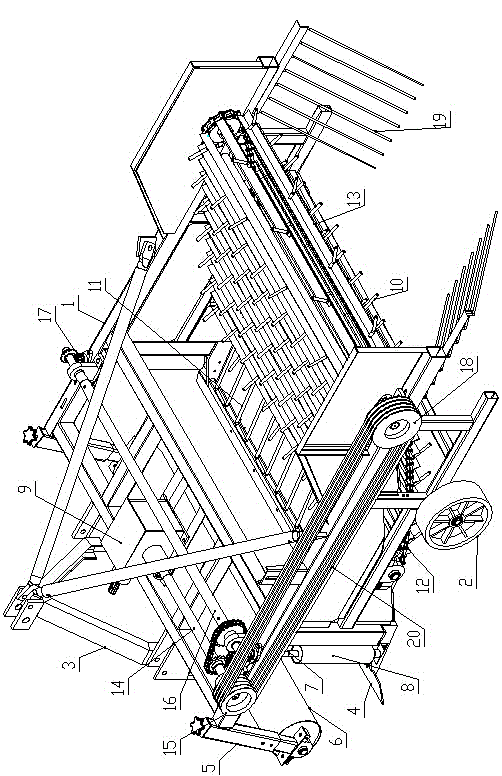

[0023] Such as figure 1 and figure 2 As shown, the hook-hung type peanut harvester of the present invention comprises a frame 1, the lower side of the rear part of the frame 1 is provided with a walking wheel 2, the upper part of the front end of the frame 1 is provided with a traction suspension frame 3 and a power speed regulating mechanism 9, and the frame 1. The lower part of the front end is provided with a blade 4 with a low front and a high rear. The front end of the frame 1 is provided with a height-adjustable bracket 5 located in front of the blade 4. The lower part of the bracket 5 is provided with a depth-fixing roller 6. Two vertical shafts 7 are vertically arranged behind the blade 4 respectively. The vertical shaft 7 is provided with an anti-winding seedling separating roller 8. The upper end of the vertical shaft 7 is connected to the power speed regulating mechanism 9. The roller shutter conveyor chain ladder is evenly provided with curved hook rods 10 for ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com