Automatic oil-water separating device and method

An oil-water separation device and automatic technology, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high cost, complicated operation procedures and low efficiency of biological methods, and achieve excellent mechanical properties, simple device structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

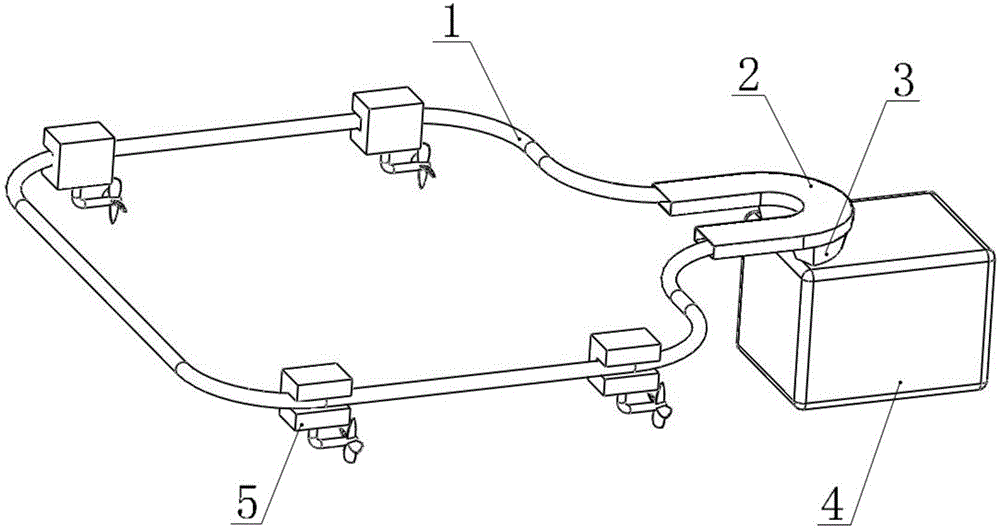

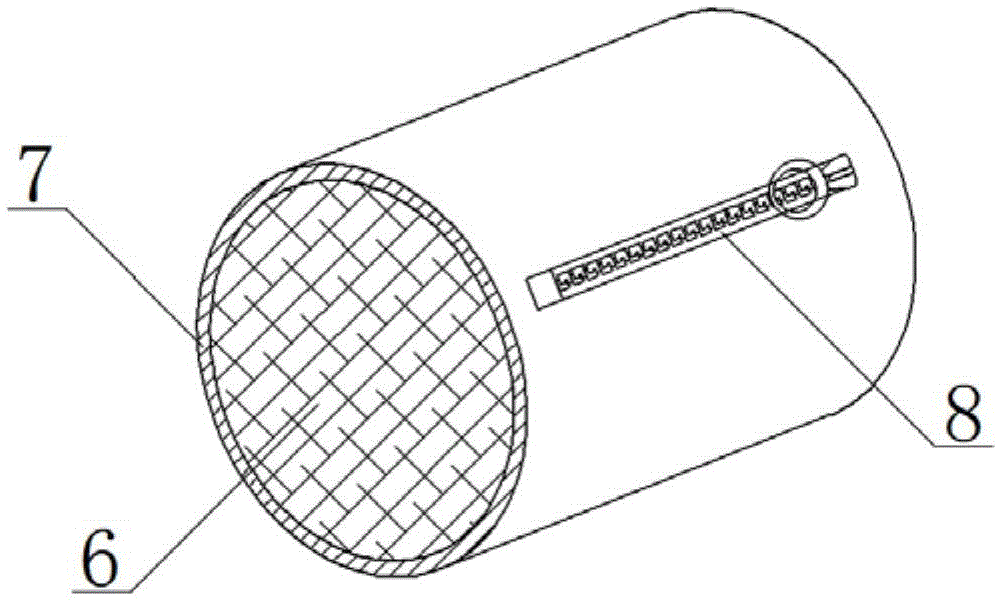

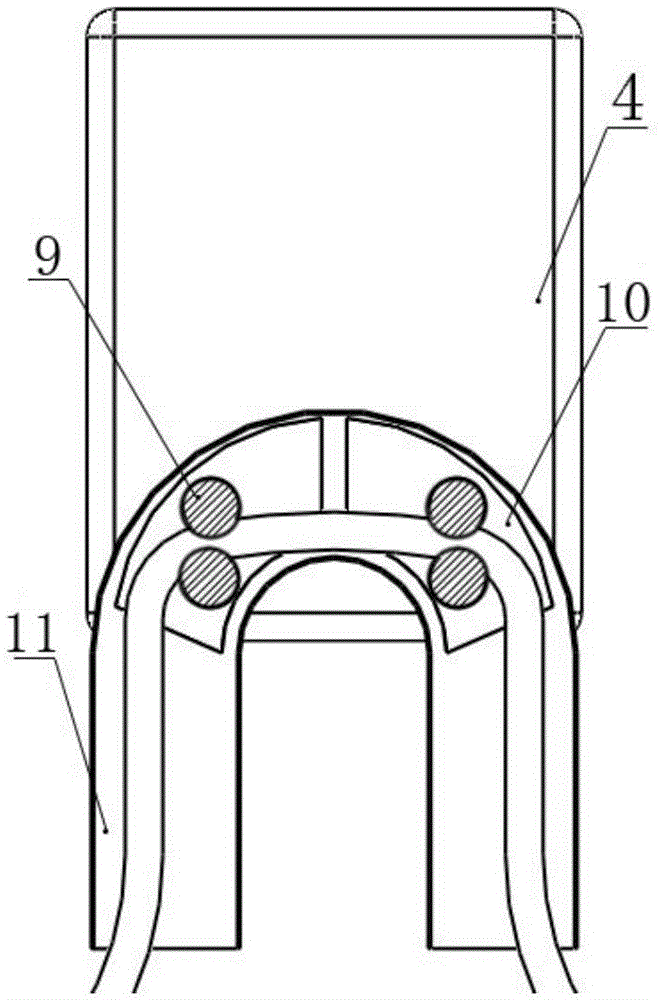

[0027] A kind of automatic oil-water separation device of the present invention, as figure 1 As shown, it mainly includes oil suction rope 1, oil suction rope transmission channel 2, oil guide tank 3, oil storage tank 4 and remote control guide rail 5. Among them, the oil-absorbing rope 1 is composed of a natural fiber inner core 6, ultra-fine polypropylene fiber felt 7 and an open zipper 8; the oil-absorbing rope transmission channel 2, the oil guide groove 3 and the oil storage tank 4 are an integrated structure, and the oil-absorbing rope transmission channel 2 is composed of rollers 9 , The oil guide opening 10 and the channel wall 11 are composed. A part of the oil-absorbing rope 1 is placed in the oil-absorbing rope transmission channel 2, and the reciprocating motion is generated through the transmission of the roller 9; the remote control guide rail 5 is composed of a guide rail bearing 12, a floating block 13 and a remote control propeller 14, and several remote contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com