Air-liquid full hybrid self-pulse washing device

A cleaning device and full-mixing technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of non-adjustable ratio of water and air, inability to use, short service life, etc., and achieve reduction The effect of initial investment cost, not easy to damage, and avoiding unsafe hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing.

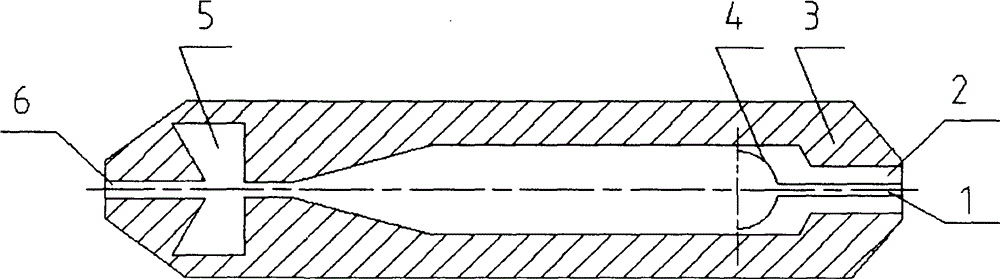

[0011] Referring to the accompanying drawings, a gas-liquid fully mixed self-pulse cleaning device includes a housing 3, the housing 3 is provided with an atomization cavity, and an atomization flow guide structure 4 is arranged in the middle of one end of the atomization cavity, and the flow guide structure The circumferential dimension of the edge of the atomization cavity is smaller than the circumferential dimension of the side wall of the atomization cavity, and the medium water inlet 1 and the compressed air inlet 2 arranged at one end of the atomization cavity are respectively connected with the atomization guide structure 4 and the cavity of the atomization cavity connected, the diameter of the cavity side wall at the other end of the atomization cavity gradually decreases toward the end of the outlet 6 opened on the housing 3, and is located in the housing 3 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com