Adjustable step drill bit

A step drill bit, adjustable technology, applied in the direction of step drill, repair drill, drilling tool accessories, etc., can solve problems such as inability to adjust, and achieve the effect of ensuring concentricity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

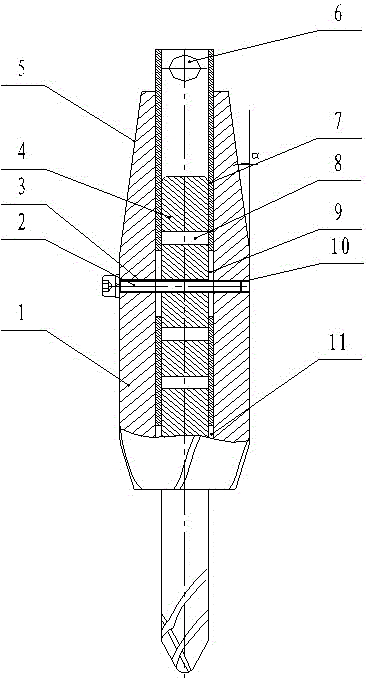

[0010] Such as figure 1 As shown, an adjustable stepped drill bit includes: a large drill bit 1, an adjusting screw 2, a small drill bit 4, and a sleeve 7. The whole big drill bit 1 is a cylindrical structure, and its center is provided with a circular through hole 11, and the circular through hole 11 runs through the whole big drill bit 1 longitudinally; Hole 10; one end of the big drill bit 1 is provided with a conical surface 5 for tight fit with the machine tool spindle; the other end is the cutting edge of the big drill bit 1. The small drill bit 4 is located in the circular through hole 11 of the large drill bit 1, and can move up and down in the entire circular through hole 11; on the small drill bit 4, 2 to 5 through holes 8 of the same size are evenly and parallelly arranged horizontally. The sleeve 7 is sleeved on the outer surface of the small dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com