A cl grid plate welding manipulator and a welding machine using the manipulator

A technology for welding manipulators and grid plates, applied in the directions of manipulators, welding equipment, welding equipment, etc., can solve problems such as restricting the reduction of production costs, and achieve the effects of improving efficiency, reducing labor intensity, and changing the inconsistency of operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

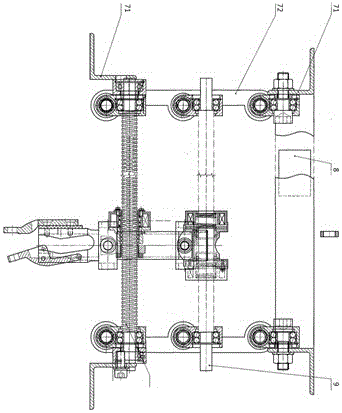

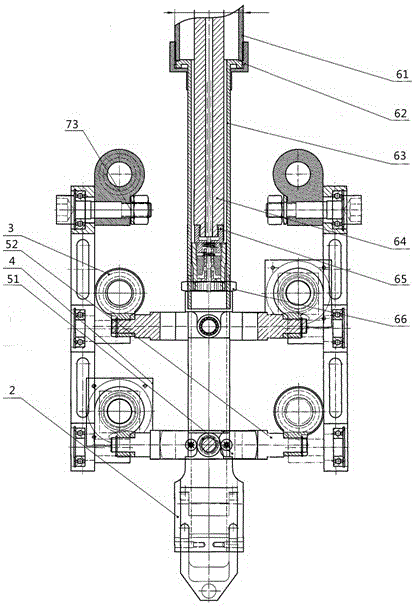

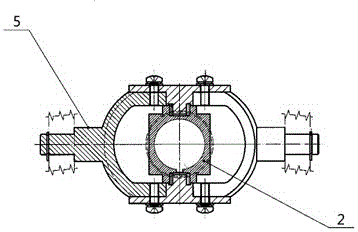

[0056] The present invention provides a CL net frame plate welding manipulator, which includes: a bracket 71, a numerically controlled machine base fixed on the support, a comprehensive broken wire machine head fixed on the numerically controlled machine base, and a hydraulic pressure machine head connected with the comprehensive broken wire machine head. Action cylinder, integrated broken wire head is installed on the numerical control machine base through universal sleeve 5, and numerical control machine base is installed on the support 71 through two short shafts 73, and integrated broken wire machine head is connected with hydraulic action cylinder by connecting sleeve 66.

[0057] The integrated wire-breaking head is composed of the wire-breaking head 2 and the wire-feeding head 1. Pushed by the wire-feeding joint 65 of the hydraulic cylinder, the spring 15 of the wire-feeding head 1 is compressed, and the taper sleeve 14 is pressed forward. Tighten the steel ball 13 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com