Automatic processing machine of erhu tube

An automatic processing and qin tube technology, which is applied in the direction of wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve the problems of difficult to guarantee processing quality, poor processing consistency, and wood chips polluting the environment, achieving high consistency, Good processing quality and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the technical solution of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the innovation and practicability of the present invention easier to understand.

[0017] The invention innovatively proposes an automatic processing machine for erhu qin tubes, which realizes automatic and high-efficiency processing of erhu qin tubes with a relatively simplified equipment structure, and is convenient for large-scale production of erhu.

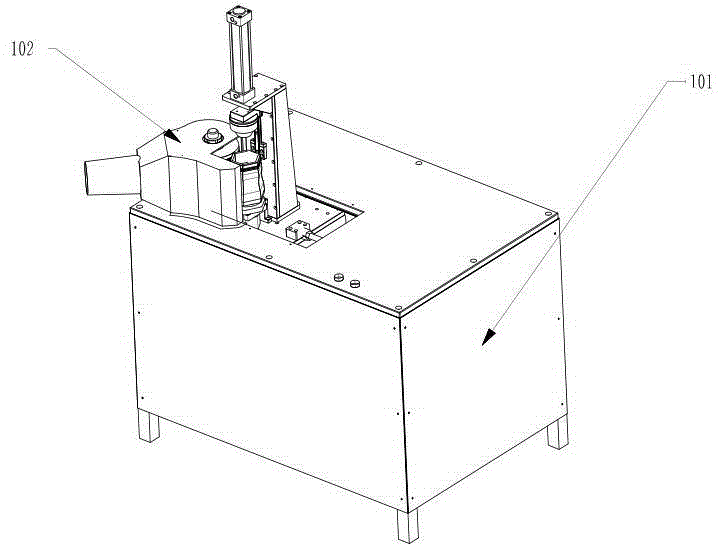

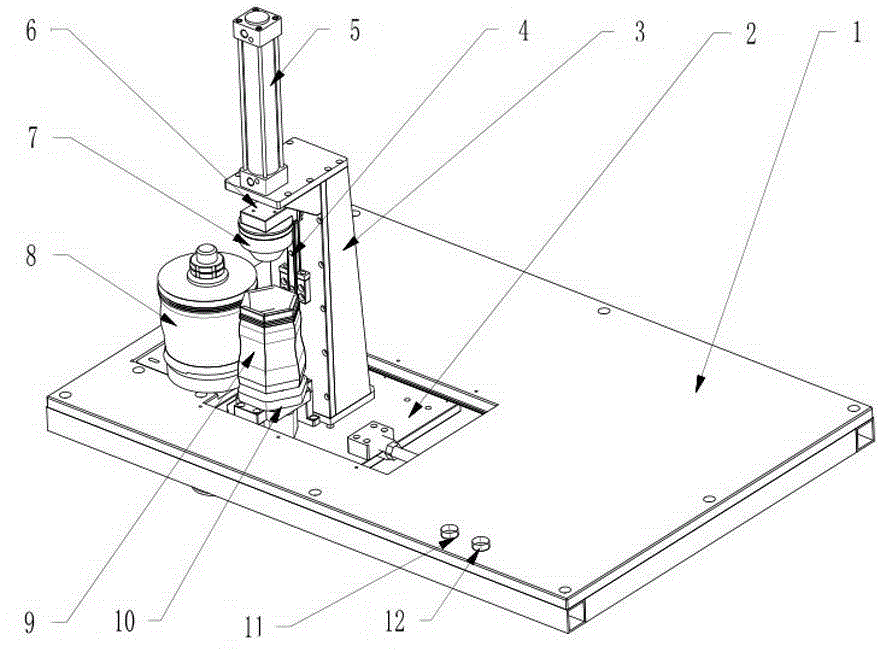

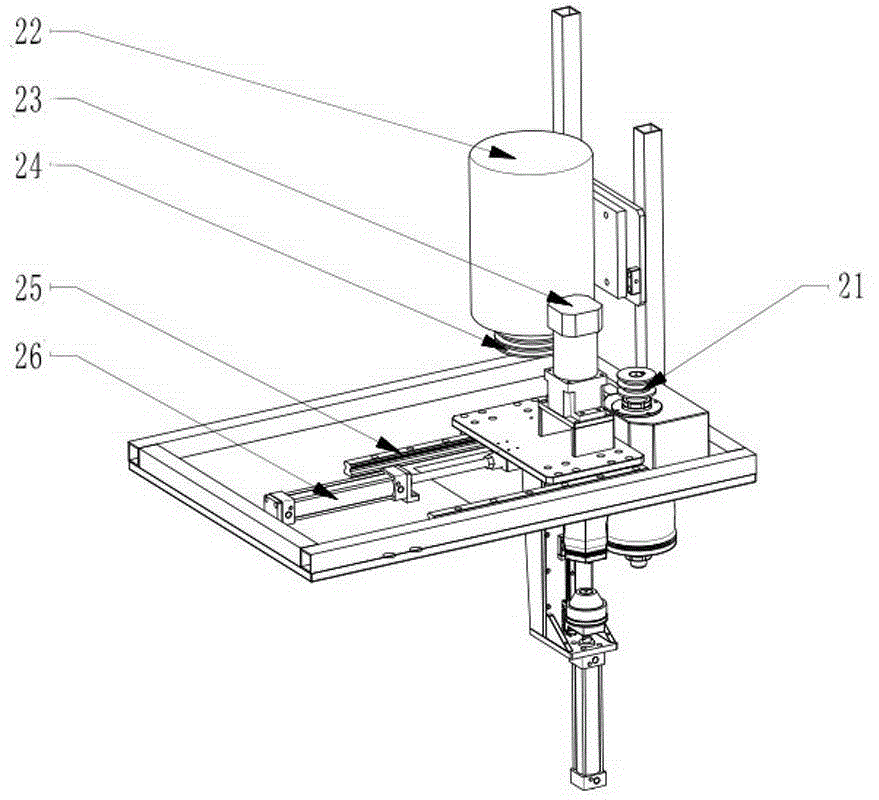

[0018] The automatic processing machine of erhuqin tube of the present invention, as Figure 1 to Figure 3 As shown, it is composed of a work table 101 and a slide unit based on the work table, a vertical pressing unit, a hexagonal positioning plate 10, a forming tool 8, a main motor 22, a servo motor 23, and an exhaust shell 102, wherein the slide unit It includes a moving guide rail 25 embedded in the working table surface 1, a moving cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com