Intermediate crusher

A medium crusher and crusher technology, applied in the direction of mechanical material recovery, recycling technology, plastic recycling, etc., can solve the problems of long-term continuous operation of production, high temperature of crushing cavity, and easy wear of tools and screens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

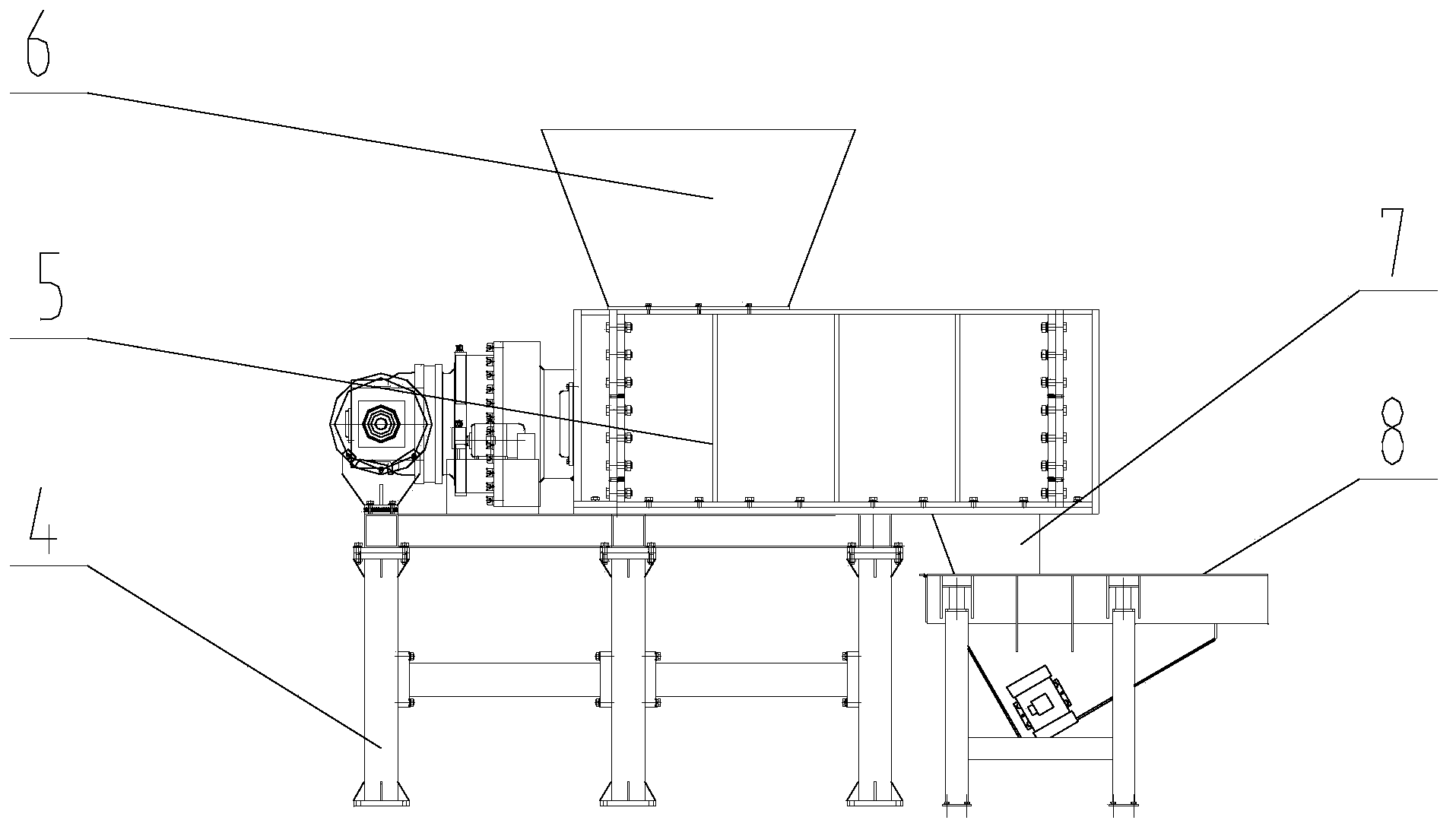

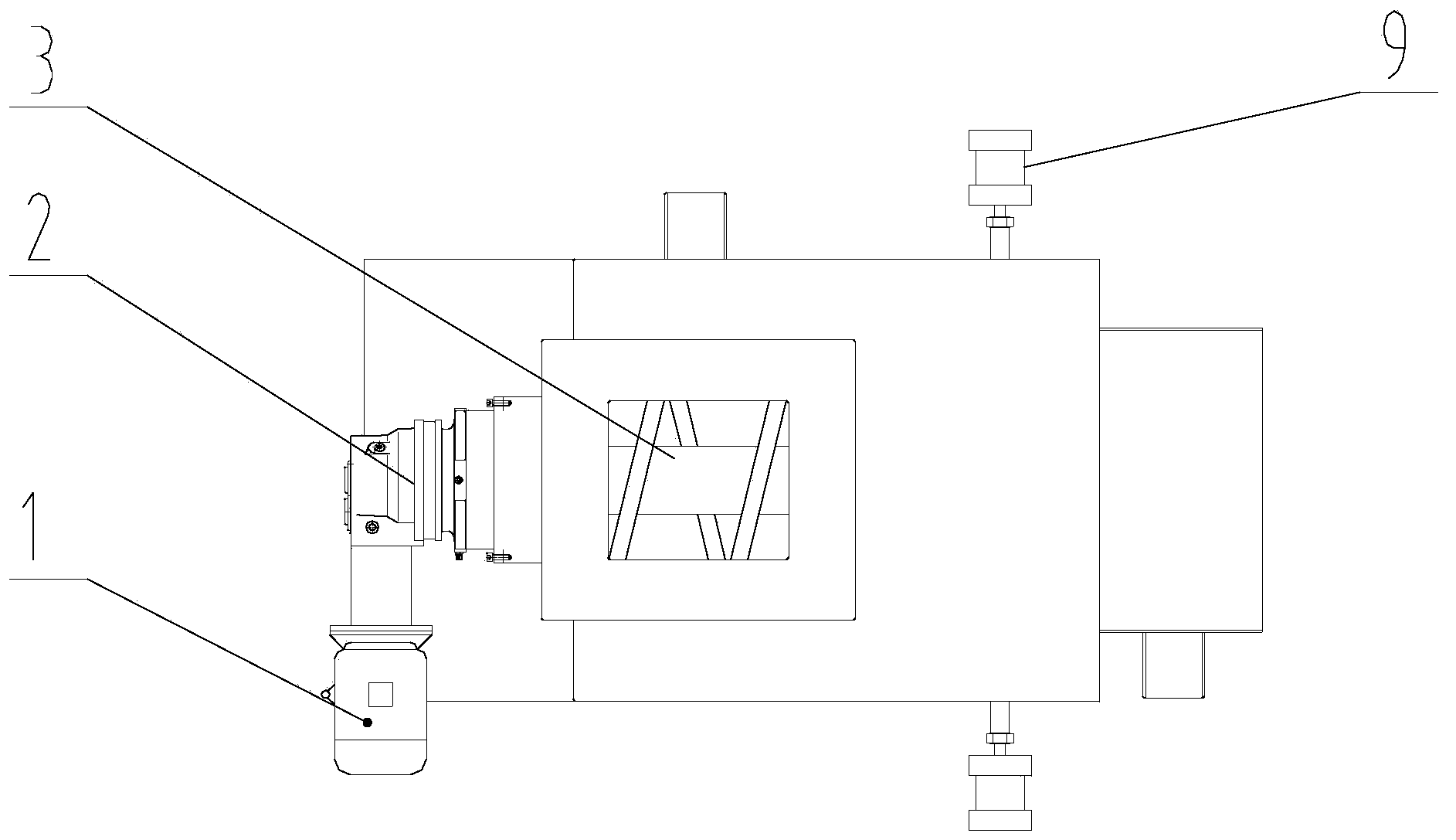

[0026] Such as figure 1 and figure 2 The shown medium crusher includes a machine chamber 5 arranged horizontally, a roller shaft arranged in the machine chamber 5, and a power device for driving the rotation of the roller shaft. The power device is arranged at one end of the roller shaft, and the machine chamber 5 also Equipped with feeding device and discharging device. Specifically, the power device includes a motor 1 and a reducer 2, one end of the motor 1 is connected to one end of the reducer 2, and the motor 1 is used to drive the reducer 2 to rotate. The other end of speed reducer 2 is connected with roller shaft, and roller shaft is helical roller 3, promptly is provided with spiral o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap