Transporting trolley for indoor GIS (Gas Insulated Switchgear) equipment and use method of transporting trolley

A technology of trolley and equipment, which is applied in the field of auxiliary equipment during the transfer of indoor GIS equipment. It can solve the problems of hoisting the car to the installation position, high safety risks, and low construction efficiency, so as to achieve low processing and production costs, improve work efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

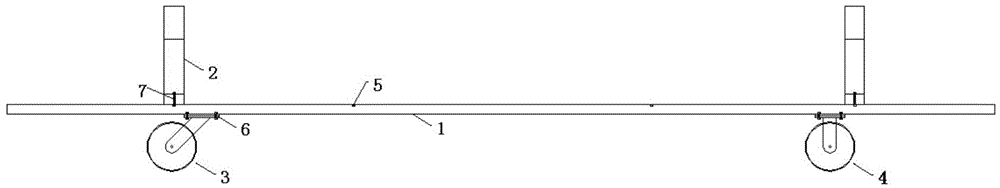

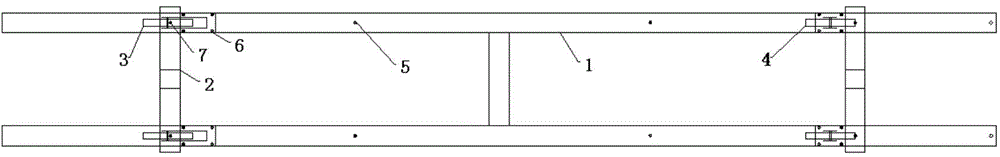

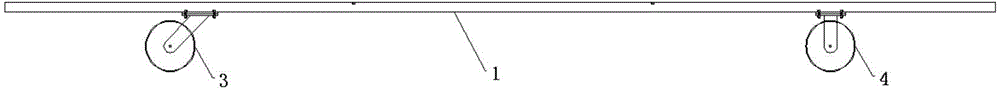

[0028] The GIS equipment transfer trolley is mainly assembled by the base, rails, support frame, support and fixing equipment, and large load-bearing rollers (see the attached figure 1 ).

[0029] Car base (see attached figure 2 , attached image 3 ) is composed of two long channel steels ([14 channel steels) and three fixed short channel steels. The two long channel steels are arranged in parallel, and the two short channel steels are perpendicular to the long channel steels. Different positions on the long channel steel of the base are provided with screw holes for adjusting the mounting screw holes 5 and load wheel screw holes 6 for adjusting the positions of the two support frames and the load wheel positions. The track of the trolley is made of [10 channel steel, which is composed of multiple channel steel welded according to the actual length, and fixed by welding with threaded steel bars. There are 2 axial load-bearing wheels and 2 universal load-bearing wheels with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com