Bowl support type automatic glaze coating device

A bowl holder and automatic technology, which is applied in the field of automatic glazing devices for daily-use ceramics, can solve the problems of high labor intensity, complex structure, and low efficiency for workers, and achieve the effects of high glazing efficiency, small size, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

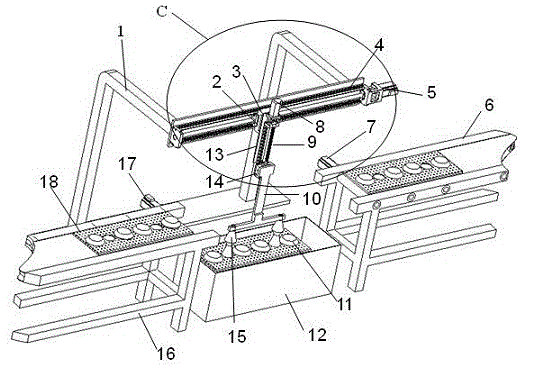

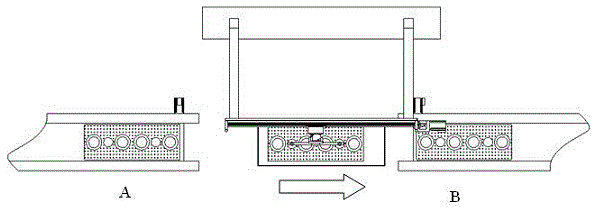

[0024] control figure 2 , 3 First, determine the position of the bowl blank 11. The bowl blank 11 is placed in the groove on the bowl holder 18, and the bowl holder 18 is placed on the transmission frame 2 16. Driven by the transmission frame 2 motor 17, the frame 2 9 will The bowl holder 18 and the bowl base 11 are sent to the station A, thereby completing the preliminary preparation of the glazing of the bowl base 11.

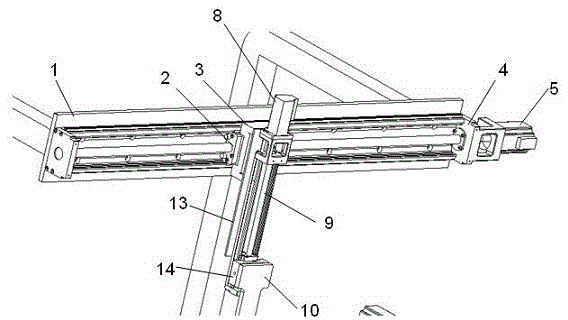

[0025] control figure 1 , the lateral movement mechanism is installed on the support 1, when the bowl base 11 is in the station A, the lateral movement motor 5 acts to drive the slider one 2, the connection block one 3, and the connection block one 3 passes through the second mounting plate 13 of the frame Drive the longitudinal movement mechanism to move to the top of the bowl blank 11 at station A, then the longitudinal movement motor 8 acts to drive the slider 2 14 to move, and the slider 2 14 drives the suction cup mounting plate 10 to move downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com