A kind of novolac epoxy coating with chemical medium resistance and preparation method thereof

A phenolic epoxy and phenolic epoxy technology, applied in the field of coatings, can solve the problems of harsh requirements, the coating is prone to blistering, peeling off, affecting the anti-corrosion effect, etc., and achieves good salt spray resistance, strong acid and alkali resistance, The effect of high solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A kind of preparation method of the novolac epoxy paint with chemical medium resistance performance, the concrete operation steps of described method are:

[0055] (1) Preparation of component A:

[0056] a. Add novolak epoxy resin and modifier in proportion to the container, stir and mix evenly;

[0057] b. Add coupling agent and defoamer in proportion in turn under stirring, stir and mix evenly;

[0058] c. Then add modified fillers in proportion under stirring, stir at high speed with a high-speed mixer to reach a fineness of 50-100um, and then add functional thixotropic agent and solvent;

[0059] d. After being uniformly dispersed at high speed, it can be made into component A in the coating;

[0060] (2) Preparation of component B:

[0061] Mix the amine curing agent and solvent in component B according to a certain ratio and stir evenly to make component B of the acid and alkali resistant coating;

[0062] The novolac epoxy coating is obtained after mixing th...

Embodiment

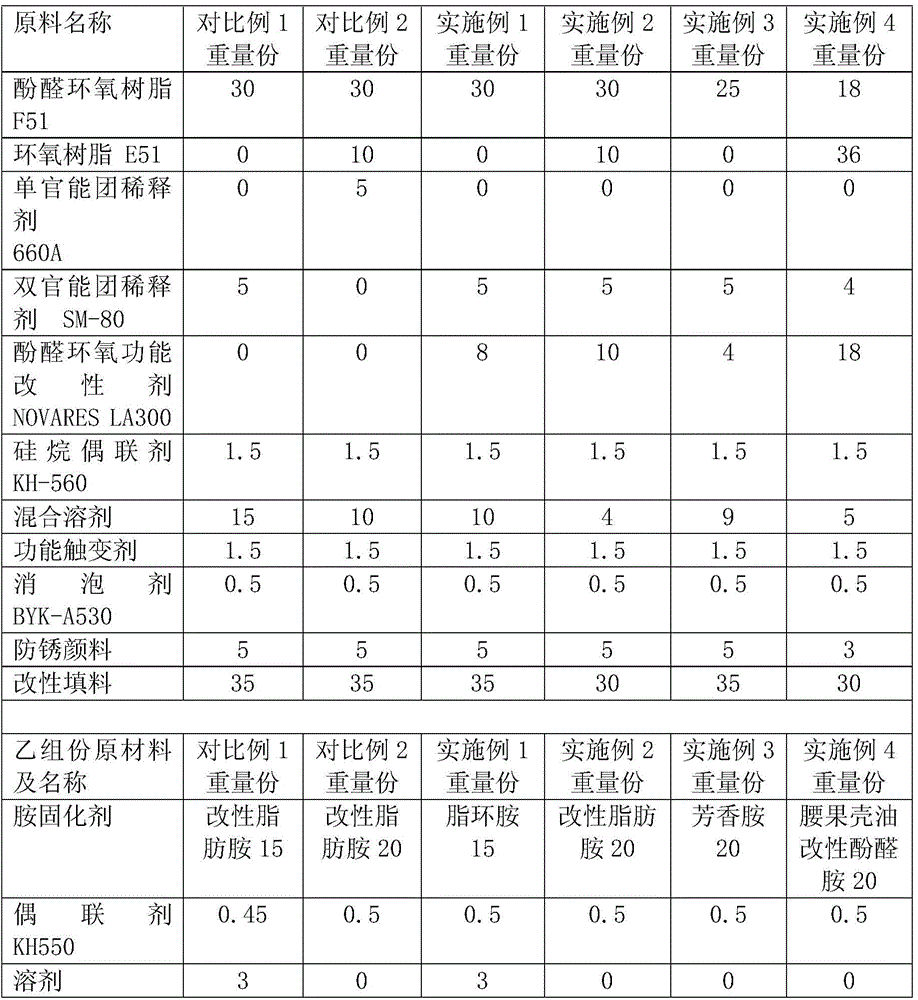

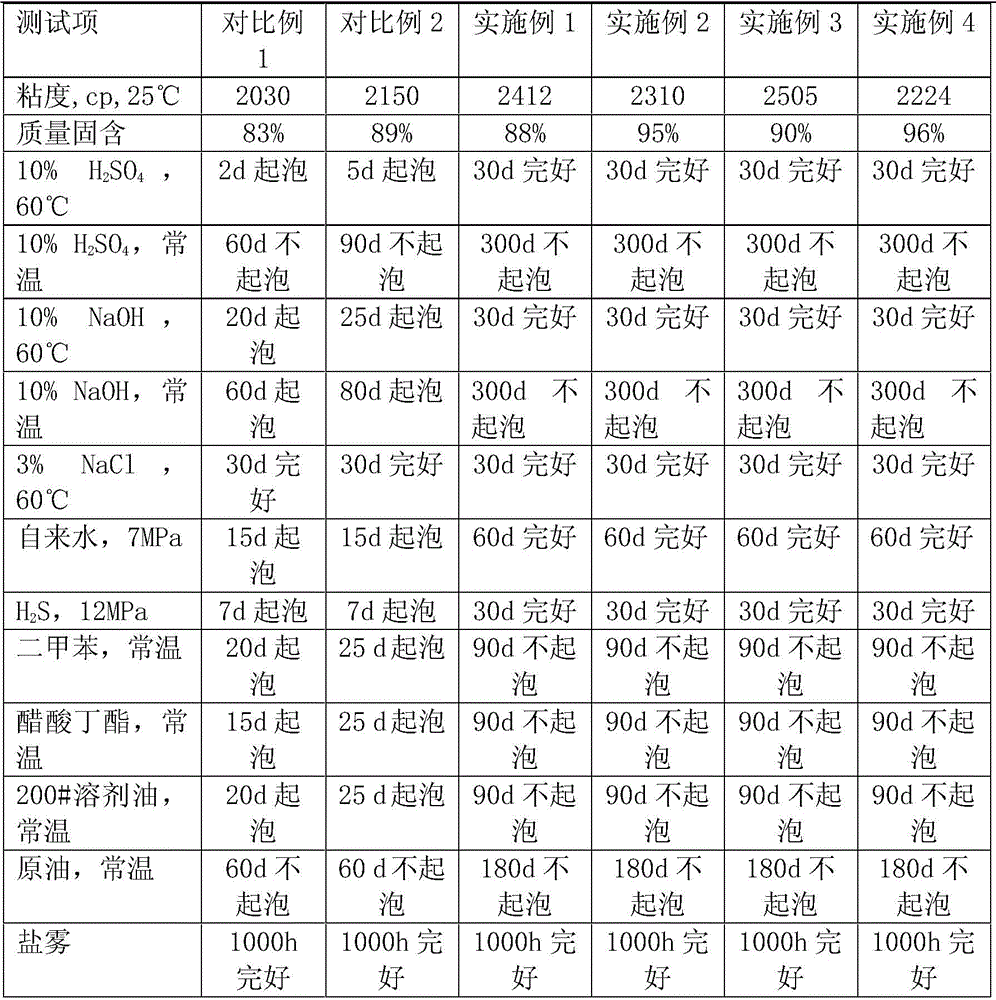

[0064] To further describe the present invention and illustrate composition and weight as follows:

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com