Ultrahigh-molecular-weight polyethylene composite material with hydrophilicity as well as preparation and application thereof

A technology of ultra-high molecular weight and composite materials, which is applied in the field of preparation of ultra-high molecular weight polyethylene composite materials, which can solve the problems of uncontrollable polyethylene molecular weight distribution, unfavorable industrial production, and lack of stability, and achieve excellent hydrophilicity , good adhesion and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

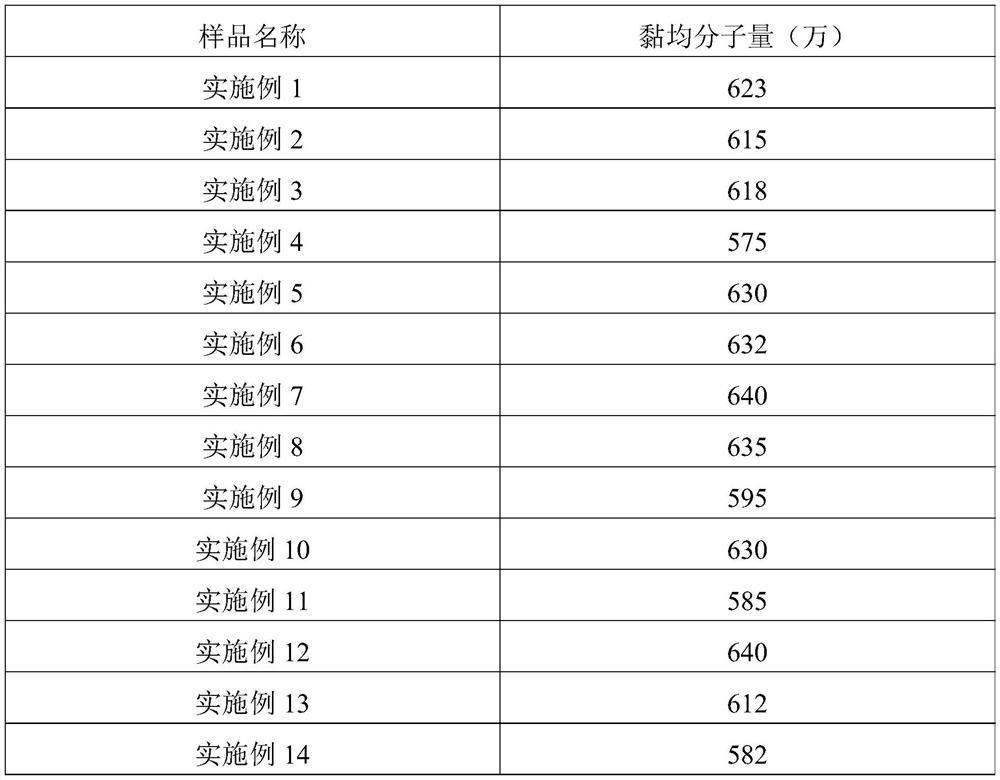

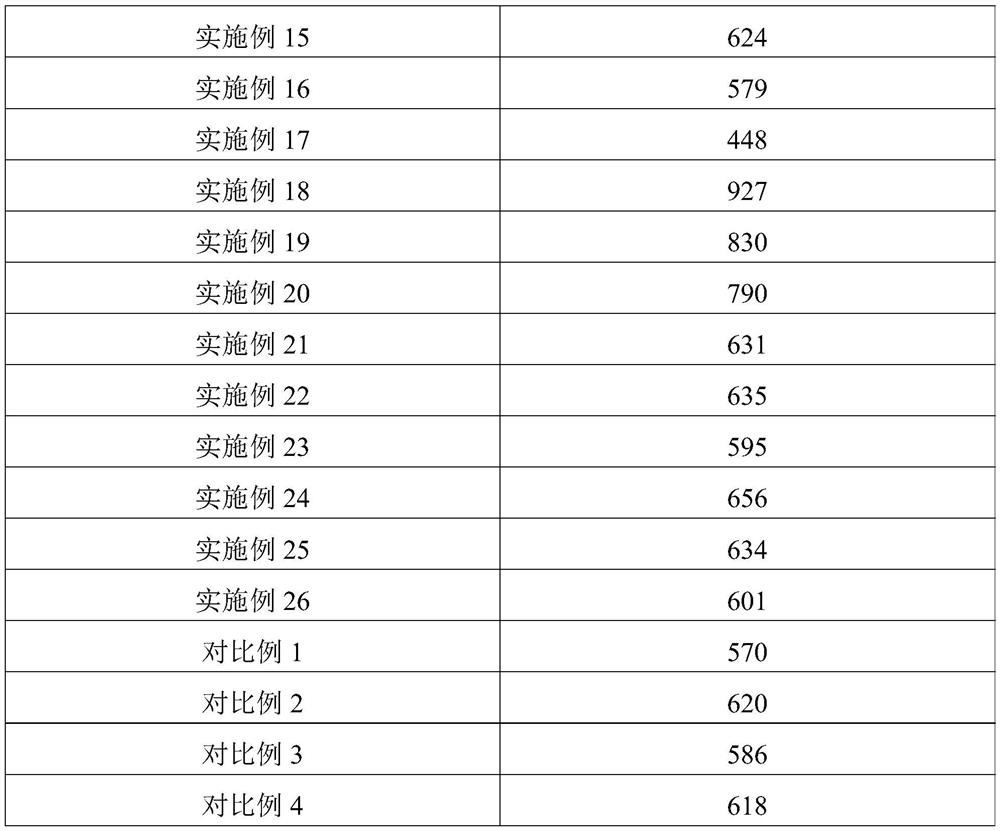

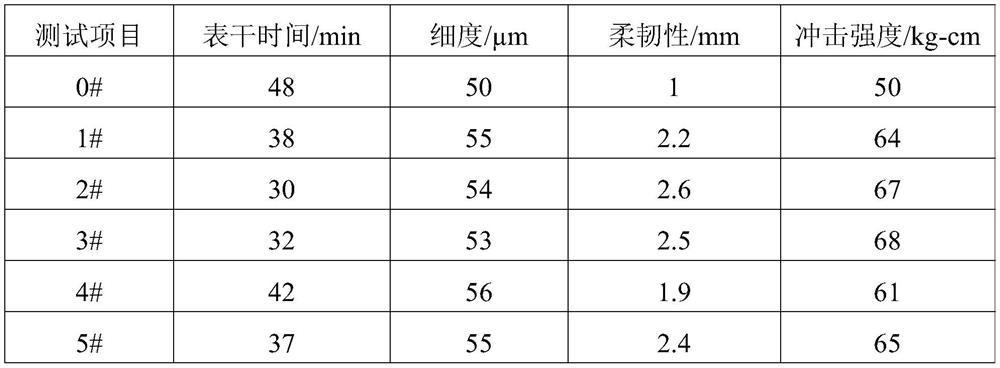

Examples

Embodiment 1

[0038] A hydrophilic ultra-high molecular weight polyethylene composite material prepared by a method comprising the following steps:

[0039] Step (1): in the autoclave of 30L stainless steel, use N 2 Replace 5 times, start vacuuming for 2 hours when heated to 45-50°C in a circulating water bath, and then add 12443g of mixed organic solvent (according to n-hexane: heptane: 1,2-dimethoxyethane: white oil = 20 %: 60%: 10%: 10% mixed, the above is mass percentage), and the mass of ethylene added is 25420g.

[0040] The mass fraction of adding 654.9g is 5% (the implication that the mass fraction is 5% here refers to that a certain amount of cocatalyst mixture is mixed with the above-mentioned organic solvent, so that its mass percentage is 5%.) mixed cocatalyst (according to trimethylaluminum: triethylaluminum: tri-n-butylaluminum=5%: 90%: 5% mixing, the above is the mass percent), finally add the Z-N catalyst of 400mg, be 58 ℃ at polymerization reaction temperature, reaction E...

Embodiment 2

[0052] Compared with Example 1, most of them are the same, except in this example:

[0053] The organic solvent used is a mixture of n-hexane, heptane, 1,2-dimethoxyethane and white oil, and the mass percentages of the four are 75%, 15%, 5% and 5% respectively.

Embodiment 3

[0055] Compared with Example 1, most of them are the same, except in this example:

[0056] The organic solvent used is a mixture of n-hexane, heptane, 1,2-dimethoxyethane and white oil, and the mass percentages of the four are 20%, 70%, 6% and 4% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com