Spraying powder used for household appliance evaporator and preparation method thereof

A technology of spraying powder and evaporator, which is applied in the direction of powder coating, coating, polyester coating, etc. It can solve the problems of missed spraying or secondary spraying, waste of manpower and resources, and low powdering rate, so as to improve the powdering rate , Improve fluidity, reduce the effect of spraying thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

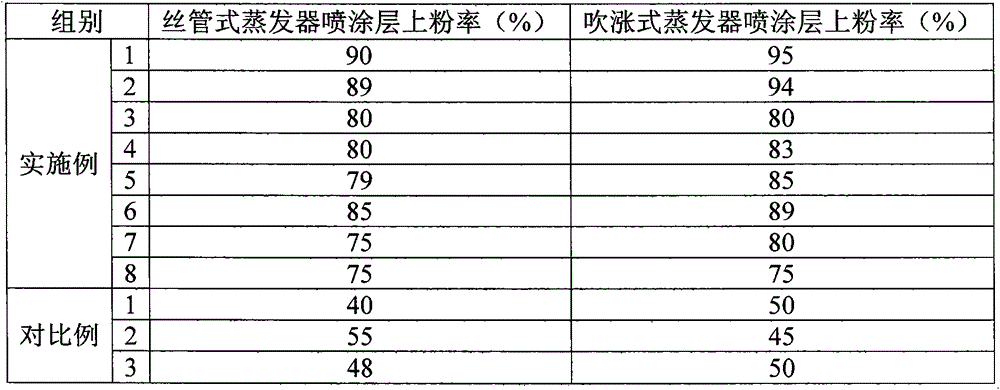

[0048] According to the conventional methods in this field, the spray powders of Examples 1-8 and the products of Comparative Examples 1-3 are used for spraying of wire tube evaporators and blown evaporators, and after spraying, they are baked and cured at a temperature of 155°C. After 15 minutes, measure the thickness of the sprayed layer if a qualified product is obtained. If a non-qualified product is obtained, repeat the spraying, and bake and cure under the same conditions until it is qualified. The sprayed coating thickness of all qualified products was detected, and the results are shown in Table 4.

[0049] Table 4 Spray coating thickness of wire tube evaporator and blown evaporator

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com