A kind of water-based polyurethane adhesive for fast-drying flexible packaging composite film and preparation method thereof

A water-based polyurethane and flexible packaging technology, applied in adhesives and other directions, can solve the problems of complex preparation process, high energy consumption, easy shrinkage, etc., and achieve the effects of simple process, high solid content and fast drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

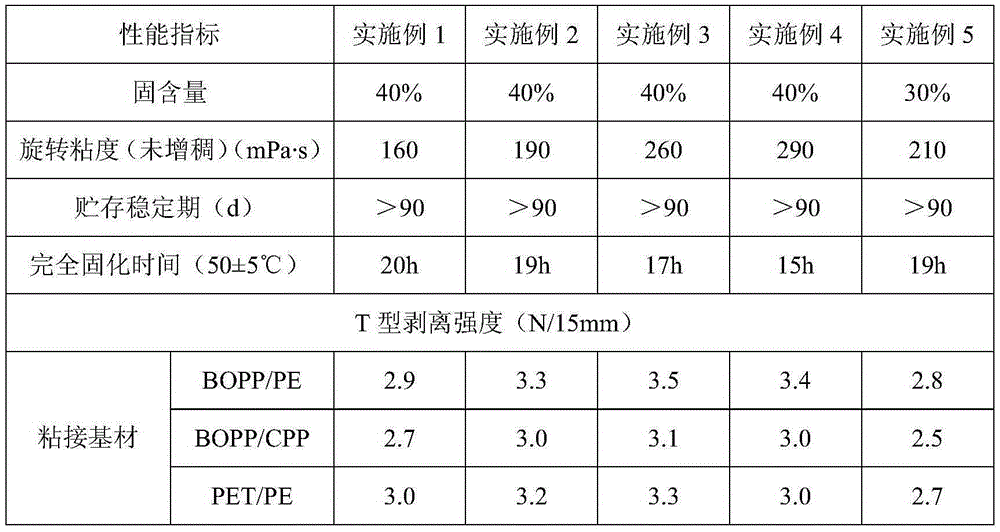

Examples

Embodiment 1

[0032] This embodiment prepares the water-based polyurethane adhesive of fast-drying flexible packaging composite film according to the following steps:

[0033] First, polyoxypropylene diol-2000 (N220) and 2,2'-dihydroxypropionic acid (DMPA) were dehydrated for 2.0 hours at a vacuum of 0.10 MPa and 90°C. Add 50g N220 and 5gDMPA into a 500ml four-neck flask equipped with a stirrer, condenser, air guide tube and thermometer, mix and stir, and introduce N 2 , Stir and mix at 75°C for 20min. Cool down to 65°C, add 25g of liquefied MDI and 0.15g of dibutyltin dilaurate under reflux conditions, keep warm and reflux for 4h; heat up to 75°C, add 2g of bisphenol A, 1.5g of trimethylolpropane (TMP), React for 3 hours; cool down to 40°C, first add 15g of acetone to reduce viscosity, then add 4g of triethylamine for neutralization and salt formation for 0.5h; slowly add 135g of deionized water under stirring for high-speed emulsification for 0.5h, and then vacuum decompression to dehydr...

Embodiment 2

[0035]This embodiment prepares water-based polyurethane adhesive in the same manner as in Example 1, the difference is that: 25g liquefied MDI is replaced by 15g liquefied MDI and 6gTDI, 5gDMPA is replaced by 4gDMPA, and the amount of deionized water is adjusted so that the solid content is 40 %. Finally, a translucent and bluish emulsion is obtained, which is the water-based polyurethane adhesive.

Embodiment 3

[0037] This embodiment prepares water-based polyurethane adhesive in the same manner as in Example 1, the difference being: 50gN220 is replaced by 9gN330 (polyoxypropylene triol-3000, trifunctionality) and 25gN220, and the addition of deionized water is adjusted so that the theoretical The solid content is 40%. Finally, a white emulsion is obtained, which is a water-based polyurethane adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com