Pre-buried guide rail and its construction method in tunnel pre-buried

A construction method and pre-embedded technology, applied in water conservancy projects, hydroelectric power stations, hydroelectric power generation and other directions, can solve problems such as insufficient operating space, and achieve the effects of ensuring installation accuracy, improving efficiency, and saving human and financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

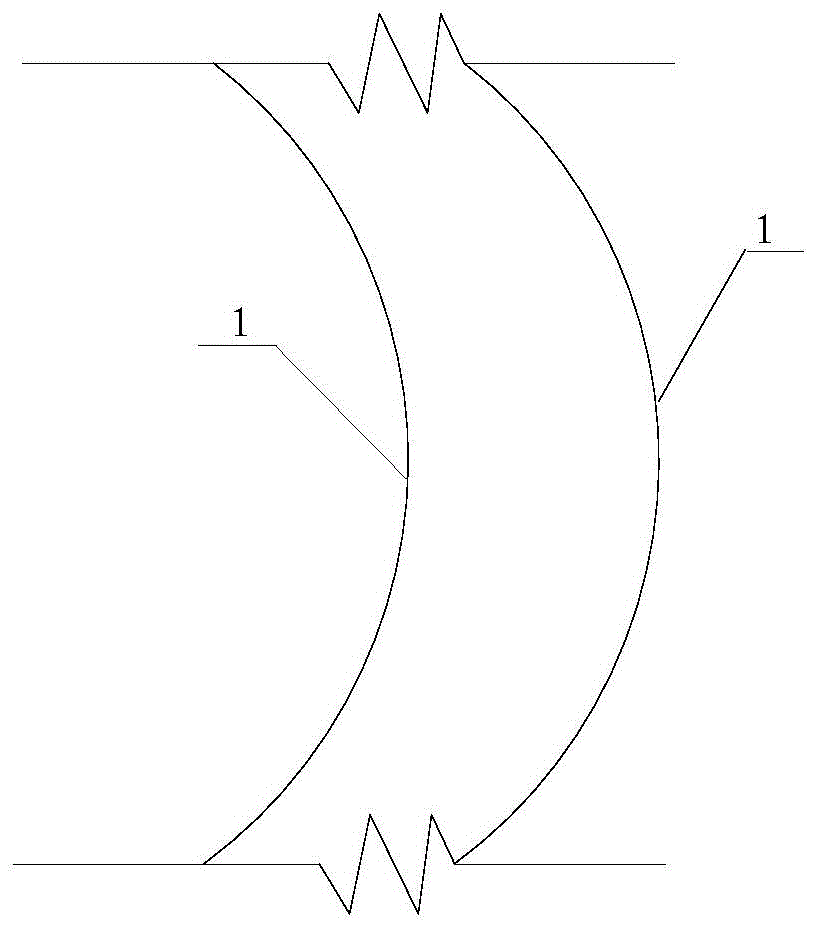

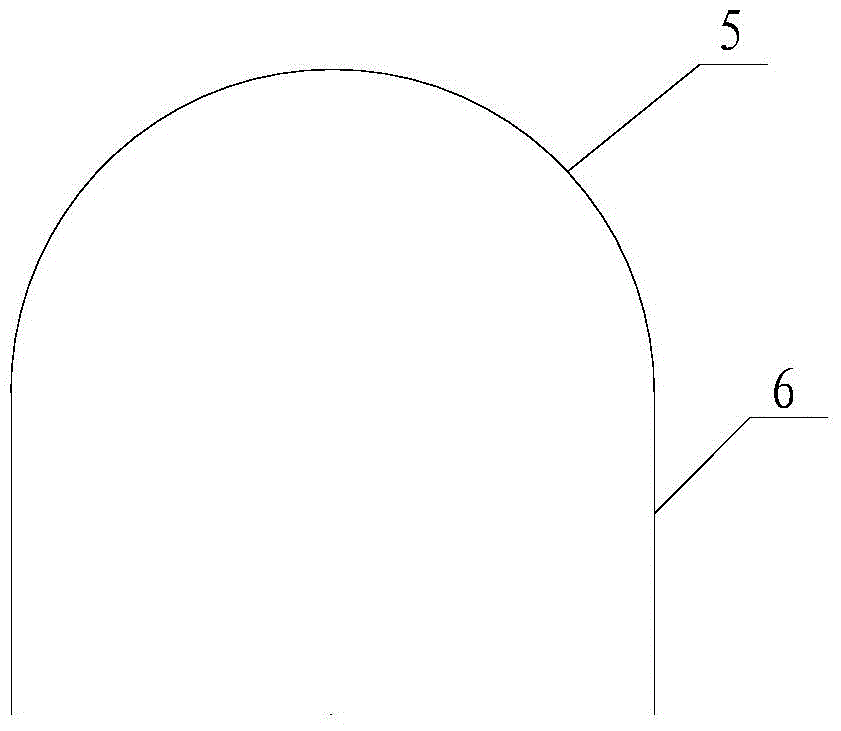

[0020] see Figure 1 ~ Figure 4 , the pre-embedded guide rail of the present invention consists of two steel bars 1 as a group, which are formed into a ring shape after bending and welding, and are laid on the surface of the entire shield-lined circular cavern before concrete pouring to form a ring road, and the head and tail ends of the pre-embedded guide rail are connected To the prefabricated anchor groove 9, the bell mouth 10 is pre-installed between the two ports of the anchor groove 9. Among the figure, 7 is the cavity wall, and 8 is the concrete bottom plate.

[0021] The distance between the two steel bars 1 is 100mm-120mm.

[0022] The steel bar 1 adopts Φ12mm~Φ14mm rebar.

[0023] The construction method of the pre-embedded guide rail in the pre-embedded tunnel includes the following steps:

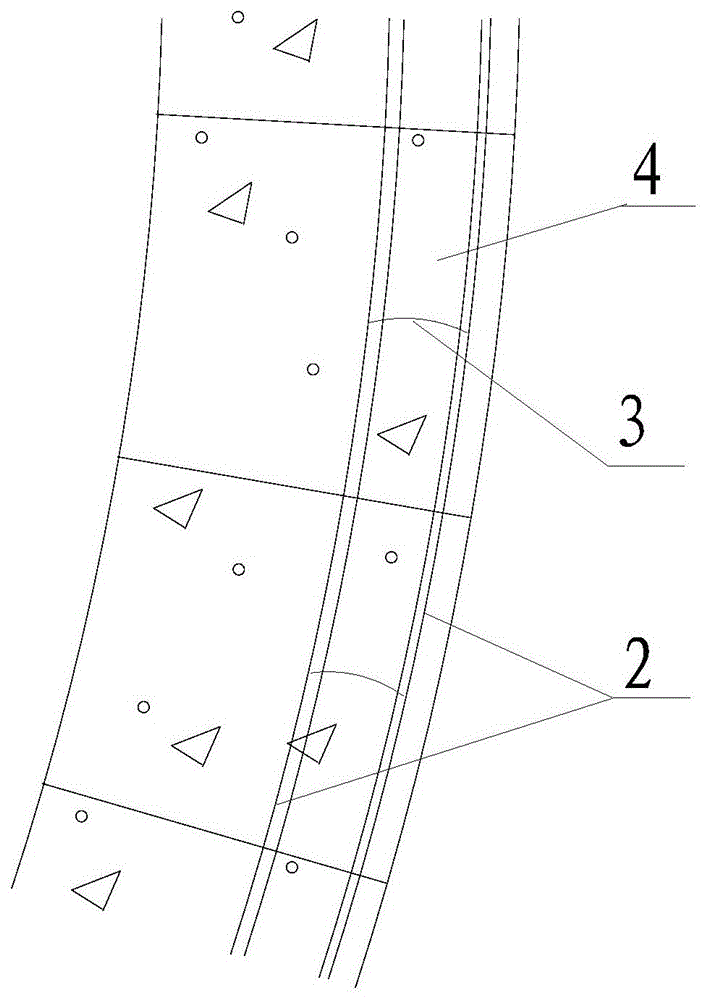

[0024] 1) Determine the installation centerline of each bellows 4 in the tunnel through measurement and positioning, and determine the installation position of the embedded g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com