Anti-leakage prefabricated component

A prefabricated component, anti-leakage technology, applied in roof insulation materials, roof drainage, etc., can solve the problems of roof leakage, short service life, high labor intensity, etc., and achieve enhanced waterproofness, long service life, and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

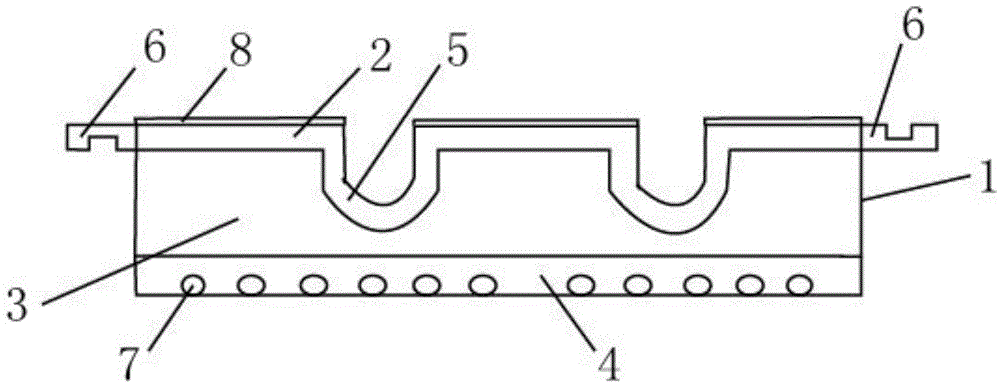

[0018] Embodiment 1: The total width of the prefabricated component base 1 is 800mm, the thickness is 120mm, the outer bottom width of the connecting groove 6 is 80mm, and the height is 40mm, the inner bottom width of the connecting groove 6 is 60mm, and the height is 20mm. Buckle up and down, the prefabricated component base 1 is coated with a 0.8-1mm thick waterproof and heat-insulating layer 8, the excrement body 4 is arranged at the bottom of the prefabricated component base 1, the drainage holes 7 are evenly distributed on the bottom of the excrement body 4, and the grooved cement board Groove 5 of 2 can be filled with cement mortar or bonding glue, and then fill and block waterproof material at the upper end of the pouring body to enhance waterproofness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com