Treatment method for upper stratum of underground gasification channel and method for building underground gasification furnace

A technology of underground gasification and treatment method, which is applied in coal gasification, underground mining, construction, etc. It can solve the problems of extinguishing the flame, lowering the temperature of the gasification furnace, and affecting the gasification effect, so as to reduce the collapse rate and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described below with reference to the drawings.

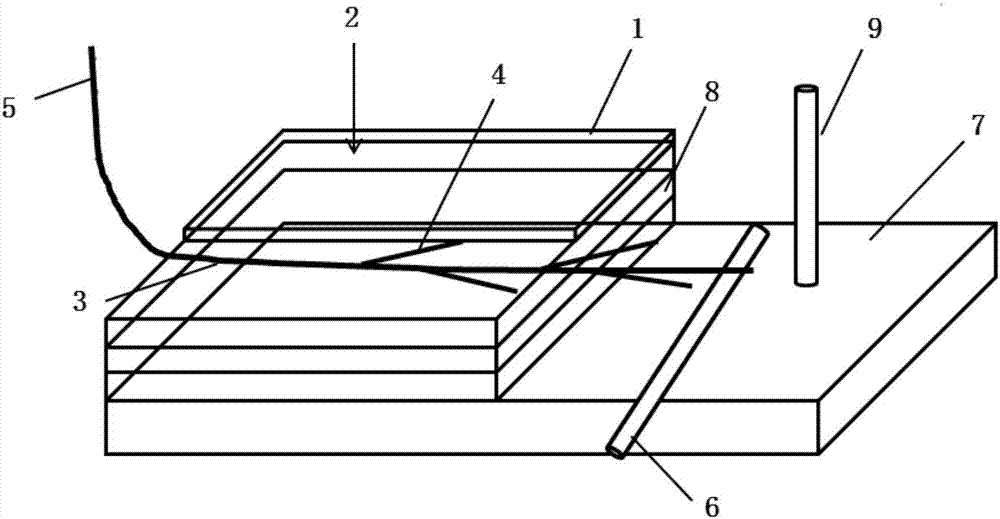

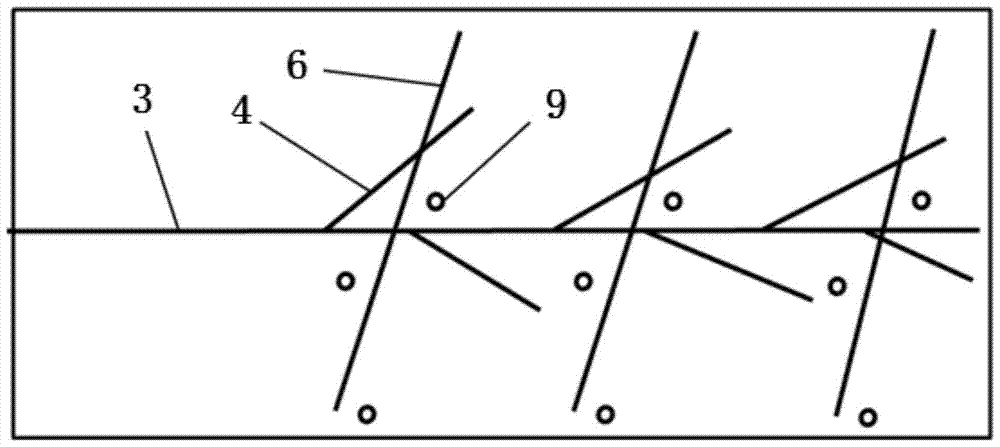

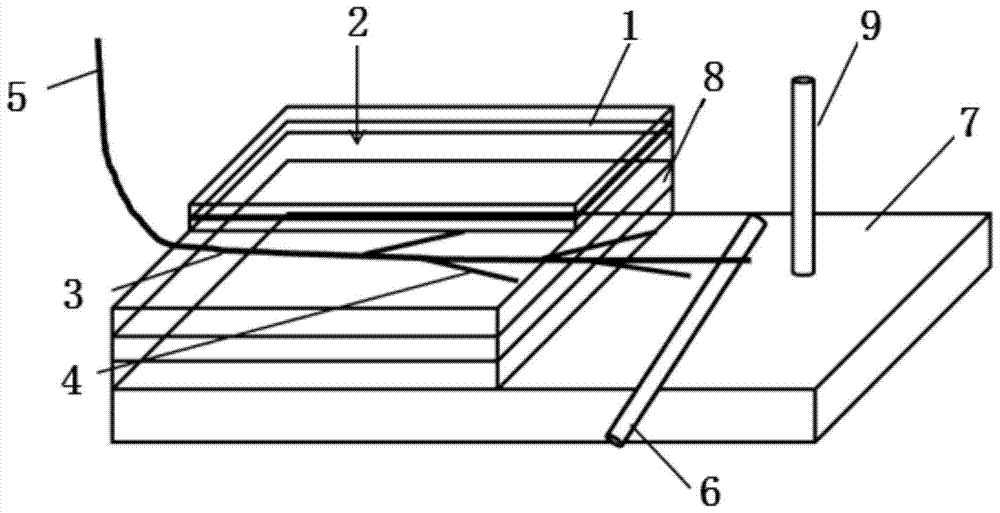

[0023] Such as figure 1 and image 3 As shown, in the two embodiments of the present invention, the formations include formations to be exploited (such as coal seams 7 or oil shale formations, etc., which can produce corresponding syngas / oil formations through processes such as gasification), and the formations located in the formations to be exploited. The strata above the stratum. further reference figure 1 and image 3 , in the following two embodiments, the stratum to be mined is the coal seam 7, that is, the stratum where the underground gasification passage is located is the coal seam 7, so in the coal seam 7, underground coal gasification is carried out from the underground gasification passage to the coal seams 7 on both sides The process, that is, the underground gasification channel is the coal seam 7 underground gasification channel. The stratum above the strata to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com