Self-propelled hollow grouting expansion anchor rod and construction method thereof

A technology of grouting bolts and expansion bolts, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of increasing bonding force and anchoring force, poor anchoring effect of grouting bolts, etc., and achieves The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

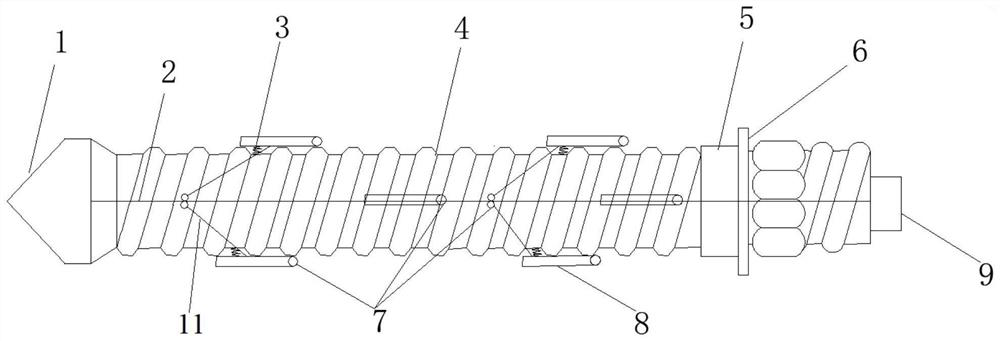

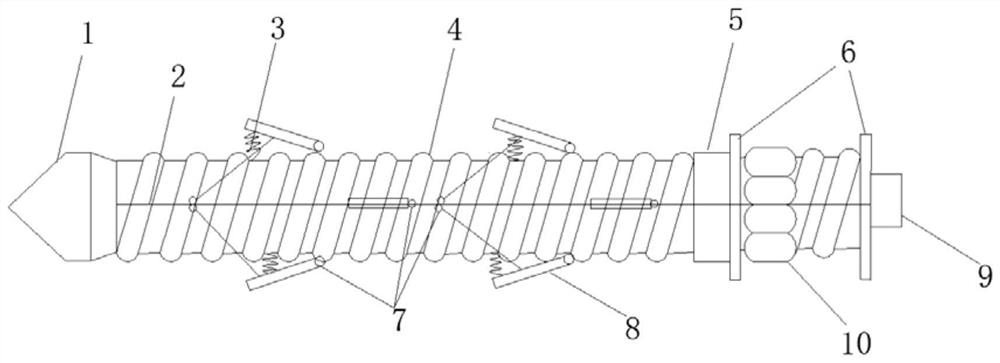

[0034] like figure 1 and figure 2 As shown, a self-propelled hollow grouting expansion anchor rod of the present invention includes a drill bit 1, an inner pull rod 2, a spring 3, an outer rod body 4, a grout stopper 5, an anchor backing plate 6, a hinge device 7, a plate shaped inverted Hook 8, valve 9 and nut 10.

[0035] One end of the hollow grouting anchor body is connected with a self-advancing drill bit 1, and the grout outlet of the drill bit 1 is connected with the grouting channel of the grouting anchor body, and the outer surface of the grouting anchor body is provided with plate-shaped inversions distributed in a cross. Hook 8, the grouting bolt body is radially processed with multiple grouting holes communicating with the grouting channel, the connecting rod 11 between the inner tie rod 2 and the plate-shaped barb 8 passes through the grouting hole, and the other end is connected with a grouting hole device, a grout stopper 5 is installed on the rear rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com