Flexible waterproof casing

A flexible waterproof and casing technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems that the sealing of rubber sealing rings cannot be guaranteed, and the horizontal entry of flange glands cannot be guaranteed, so as to achieve sealing Good performance, good anti-seismic effect, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

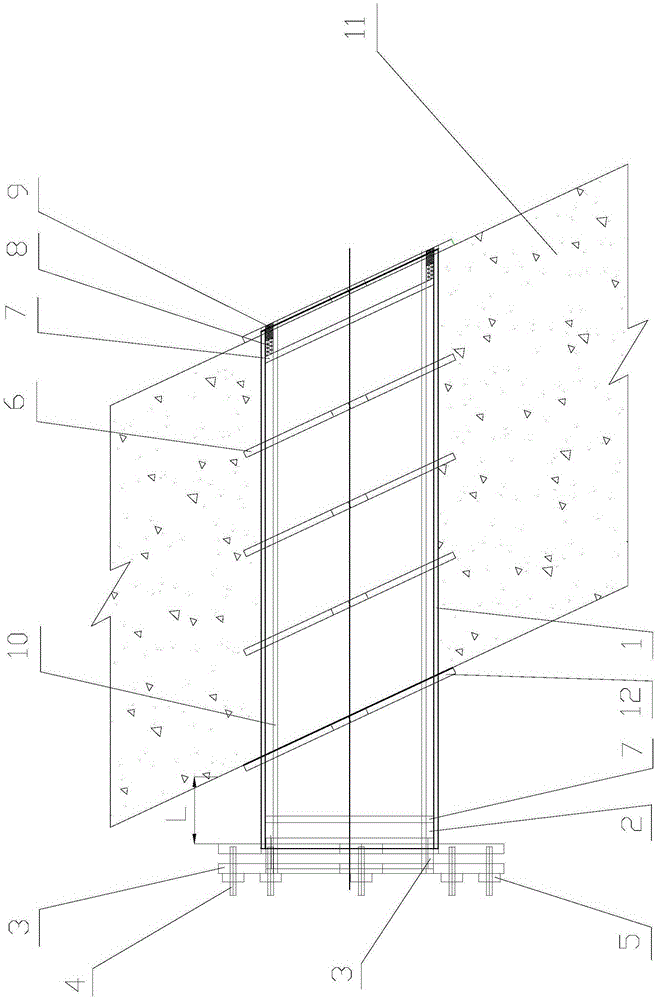

[0021] The technical solution of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings. In the shown embodiment, it is shown as the application of the present invention on the funnel-shaped concrete base 11 (the upper opening is large and the lower opening is small).

[0022] The flexible waterproof casing of the present invention includes a flange casing 1, a steel pipe 10, a rubber sealing ring 2, a flange gland 3, a screw 4, a nut 5, a water stop ring 6, a sealing material support ring 7, a flexible caulking material 8 and Locate flange 12.

[0023] The steel pipe 10 is coaxially arranged in the flange casing 1, and the positioning of the steel pipe 10 is realized by the sealing material supporting ring 7 at both ends, and the sealing material supporting ring 7 is arranged in the ring between the steel pipe 10 and the flange casing 1. cavity. The flange sleeve 1 horizontally traverses the concrete base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com