Method for preparing electrowetting display support plate

An electrowetting display and support plate technology, applied in optical components, optics, instruments, etc., can solve the problems of difficulty in controlling the dissolution rate and flatness, and can not fully solve the problem of reflow, and achieve the effect of solving the problem of reflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

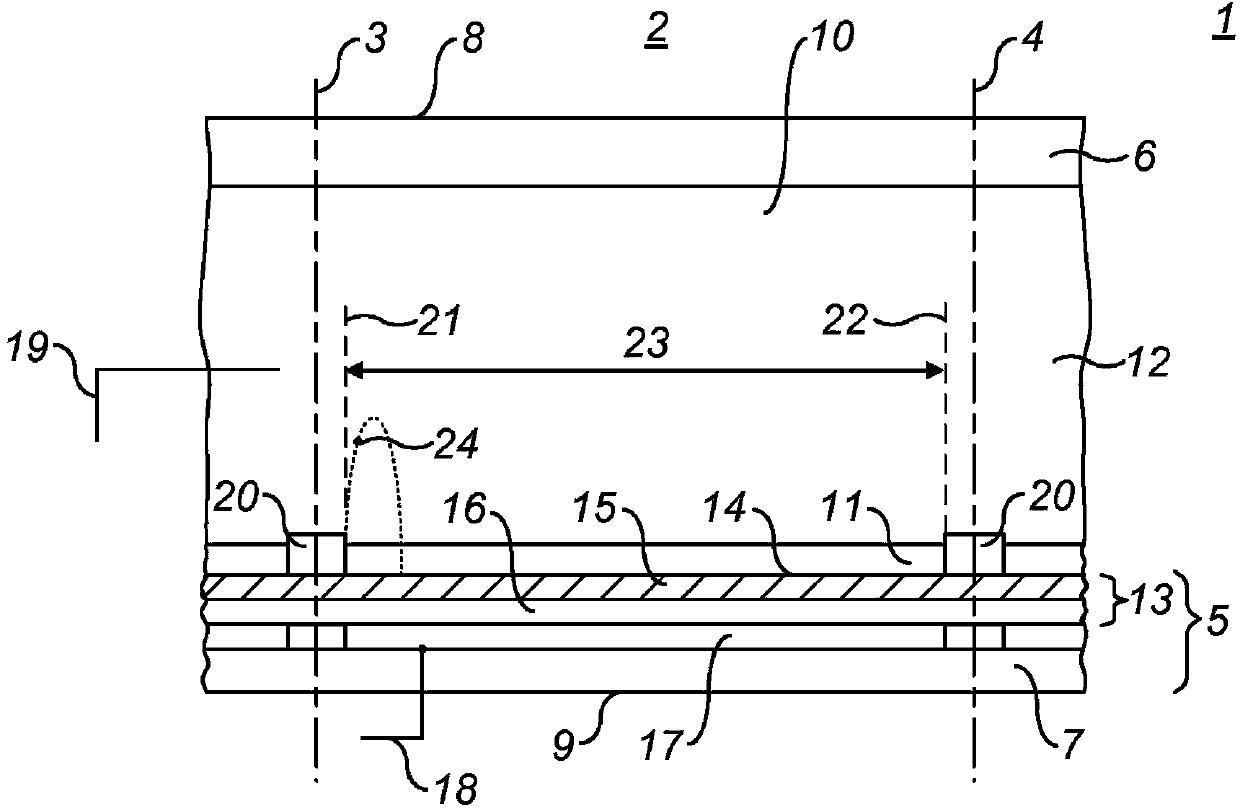

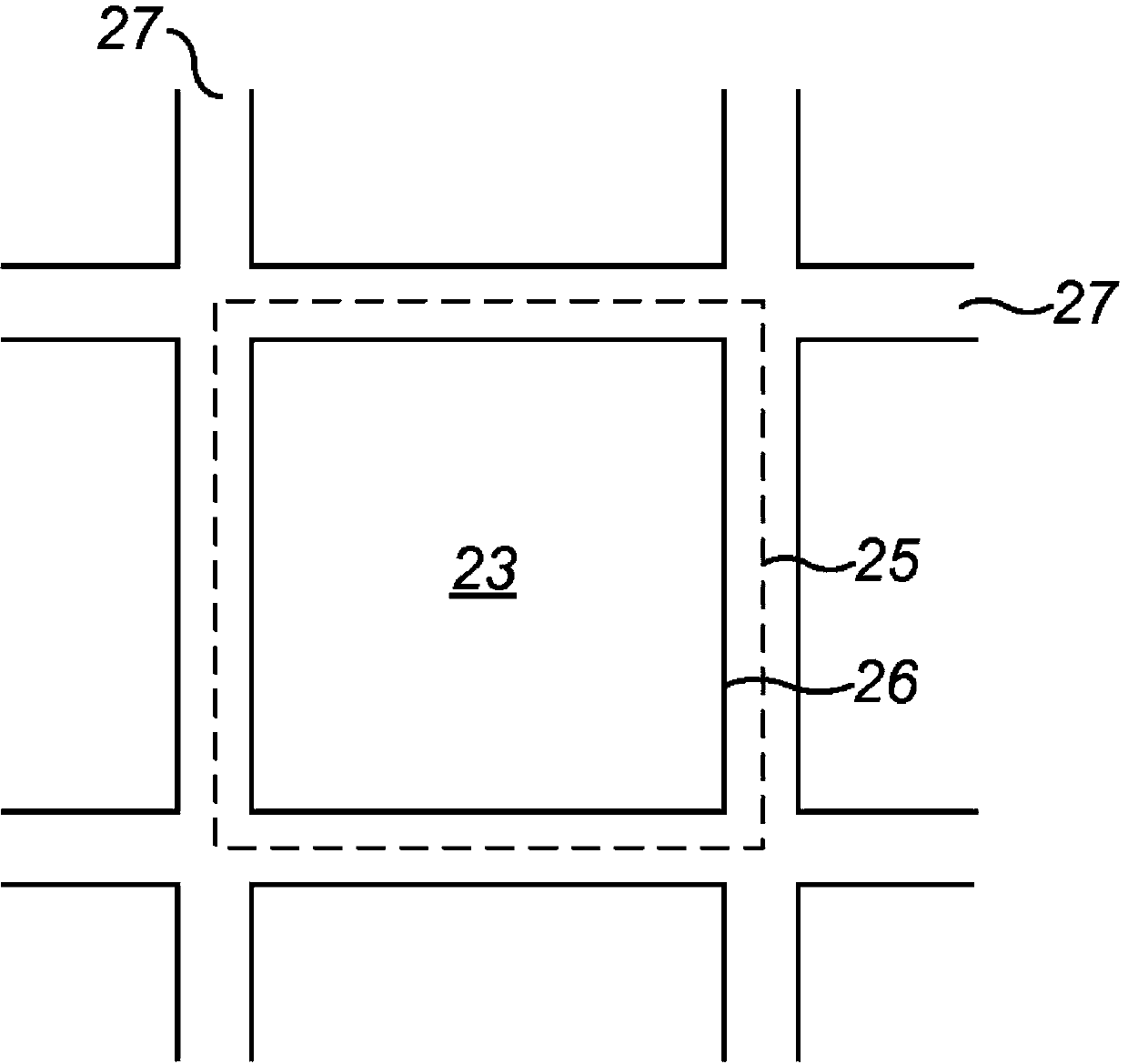

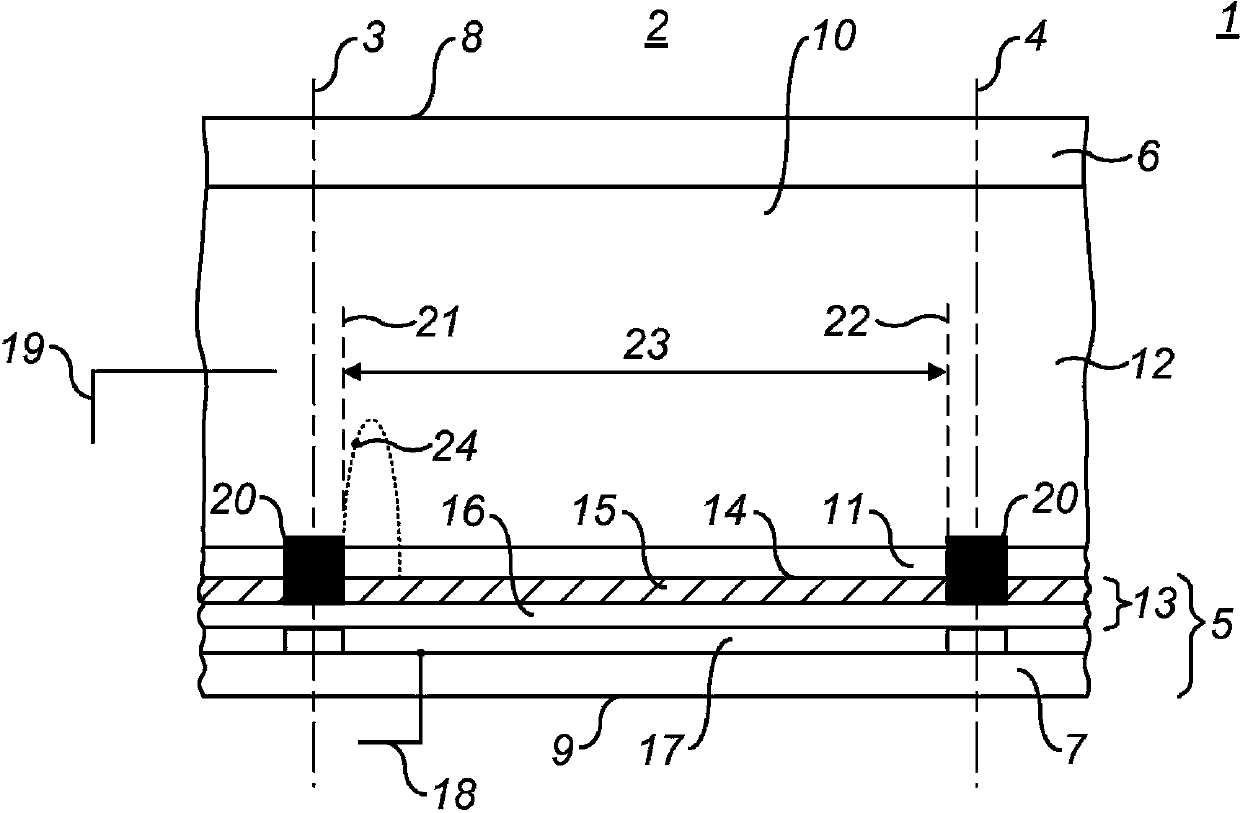

[0030] Figure 1a It is a side view of a pixel structure based on the existing electrowetting display technology, Figure 1c It is a side view of the pixel structure according to a specific embodiment of the present invention. According to the method of the present invention, an electrowetting display structure similar to that of the prior art can be manufactured. One of the most important improvements compared with the prior art is: Such as Figure 1c As shown, the pixel wall 20 is disposed on the first support plate 5 , more specifically, disposed on the dielectric layer 16 or the first electrode 17 instead of the hydrophobic layer 15 . Figure 1b Shown is a top view of the pixel structure.

[0031] Refer to the following Figure 1a-1c , to describe in detail the electrowetting pixel structure according to the present invention, wherein the pixel structure is the basis of constituting an electrowetting pixel unit. refer to Figure 1c , as an exemplary embodiment accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com