Substrate and process for mounting chip on substrate

A substrate and chip technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high surface flatness requirements of substrate pads, failure of solder joints of LED chips in formal installation, and yellowing of substrate reflective layers, etc., to achieve improved Solder joint reliability, reduced risk of solder joint failure, effect of reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with regard to the method for mounting LED chips on a flexible substrate and the flexible substrate formed therefrom. However, those skilled in the art can understand that the present invention is not limited to mounting LED chips on a flexible substrate, but can be extended to mounting any type of electronic chip on any substrate.

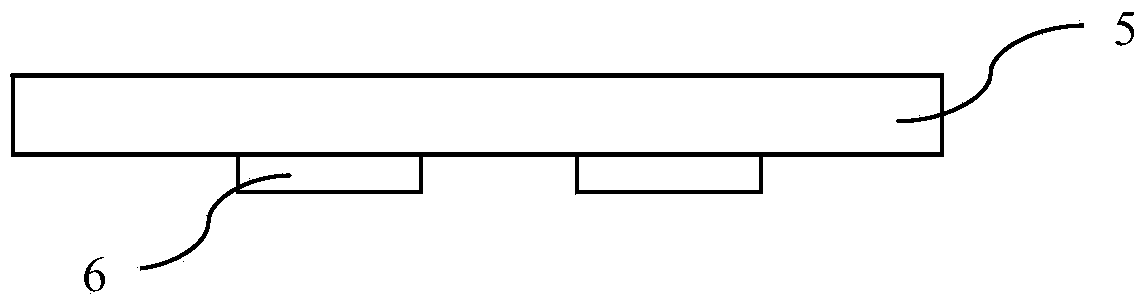

[0031] figure 1 Schematically shows an LED chip 5 to be mounted on a flexible substrate, which is, for example, a front-mounted LED chip. As shown in the figure, the LED chip 5 includes two spaced apart electrodes 6 . The electrodes are used to connect with the flexible substrate. In a non-limiting embodiment, the size of the electrodes 6 is about 100 μm, the distance between the two electrodes is greater than 150 μm, and there is a height difference between them of 5-15 μm. The material of the surface layer of the electrode 6 is usually Au.

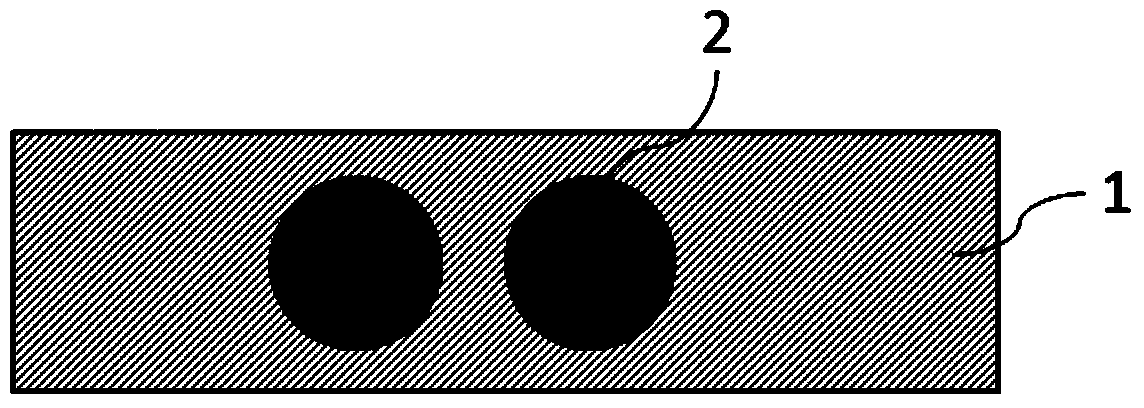

[0032] Figure 2a A substrate 1 is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com