Method and edger for machining of special-shaped glass beveled edges

A special-shaped glass and processing method technology, which is applied to machine tools, grinding racks, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, can solve problems such as labor-intensive, time-consuming, and material-intensive, and achieve improved work efficiency and better performance. The effect of marketing prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to further illustrate the method of the present invention, now describe in detail in conjunction with a preferred embodiment of the present invention shown in the accompanying drawings, but said embodiment is only for illustration and explanation purposes, can not be used to limit the patent protection scope of the present invention .

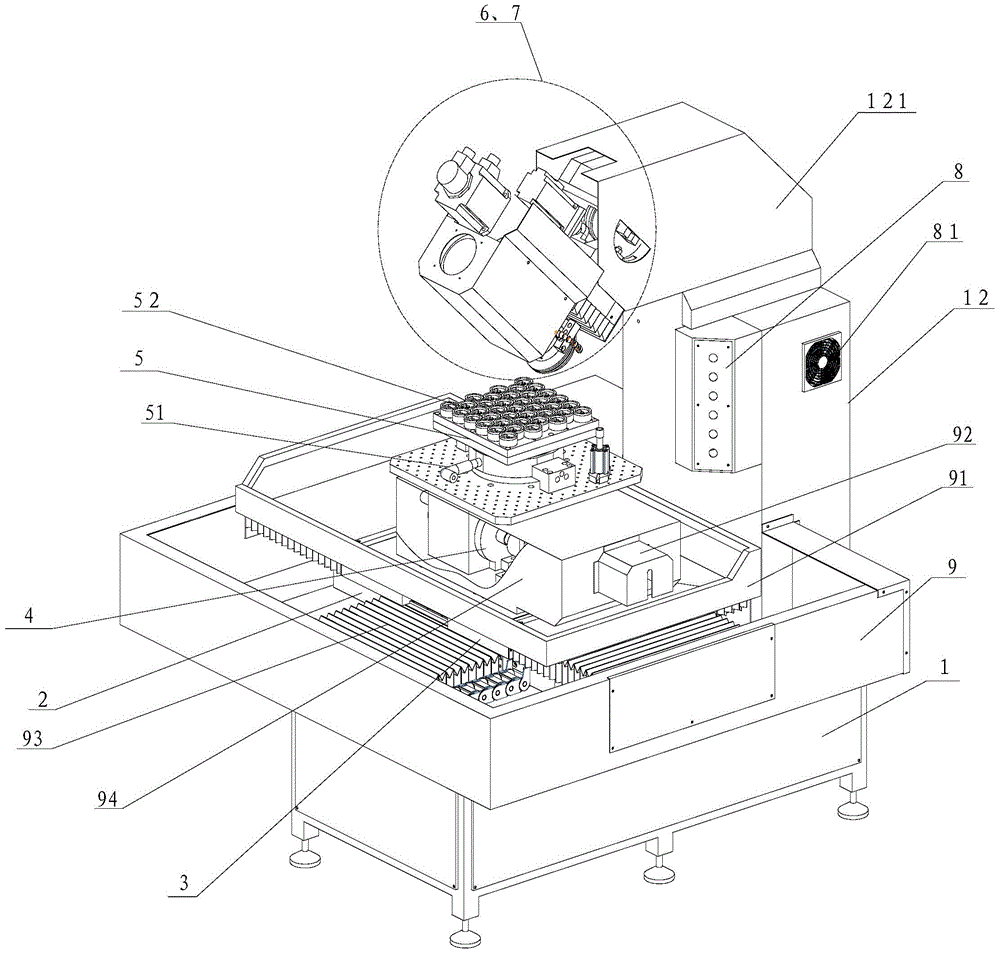

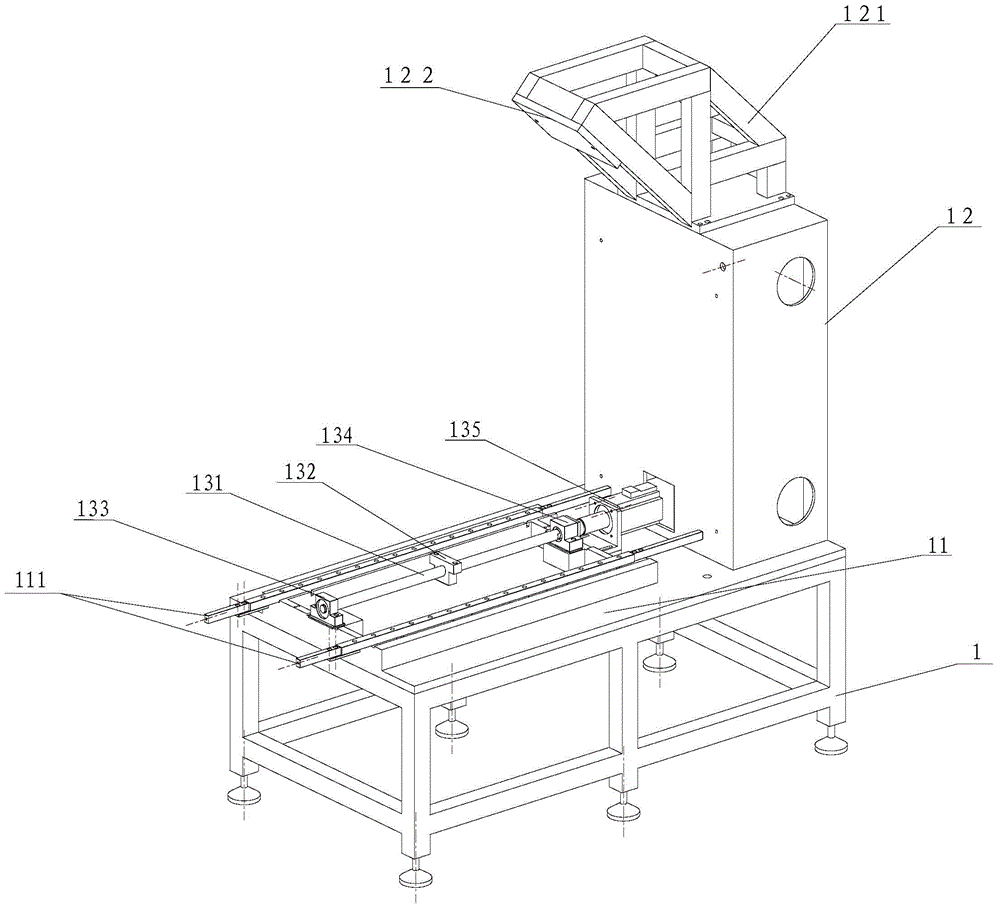

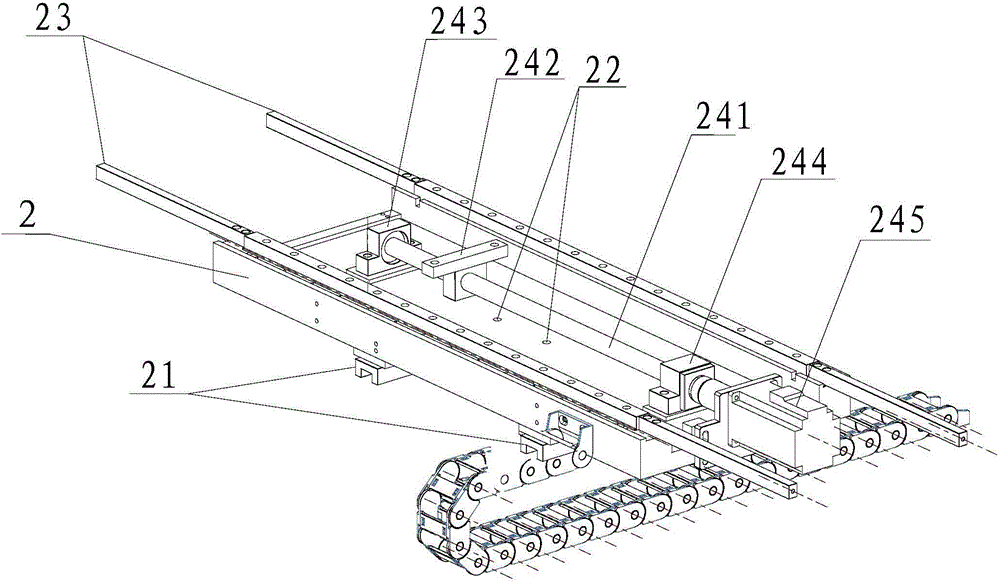

[0073] Such as Figure 1 to Figure 8 As shown, implement a kind of method of processing special-shaped glass bevel, described method comprises the steps:

[0074] ① Prepare a frame 1, the frame 1 includes: a horizontal guide rail pair 11, a column 12, a first horizontal transmission screw pair 13; the horizontal guide rail pair 11 has two guide rails 111, along the Y-axis direction in the same horizontal plane Symmetrically arranged in parallel; the top of the column 12 has a bracket 121 and a seat plate 122; the first horizontal transmission screw pair 13 includes: a first screw 131, a first nut 132, a first screw front suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com