Code printing device

A driving device and a coding technology, applied in printing, stamping, etc., can solve the problems of the coding device being uncomfortable and the machine head occupying a large space, etc., and achieve the effects of good stability, average force, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A coding device of the present invention is described in detail below in conjunction with specific embodiments:

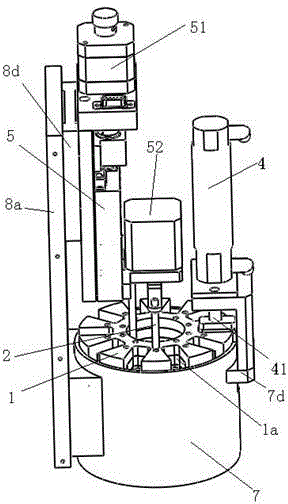

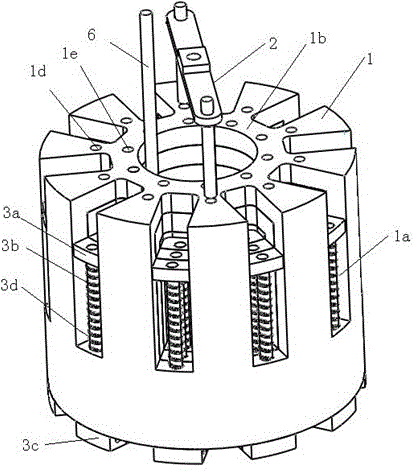

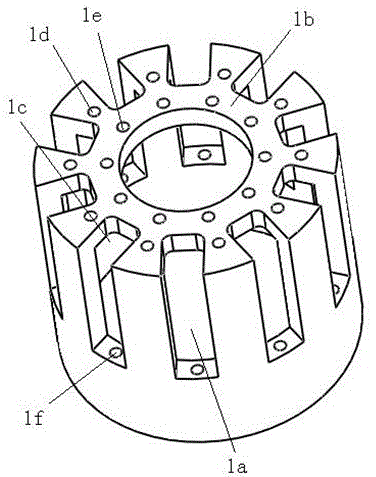

[0038] Such as figure 1 and figure 2 Shown is a coding device disclosed in the present invention, including a coding mechanism for changing codes, and an indenter device 4 for printing predetermined codes to preset positions, wherein the coding mechanism includes at least one A dial 1 with a hollow cylindrical structure, the dial 1 is provided with several installation grooves 1a along the axial direction; a driving rod 2 that drives the dial 1 to rotate around the central axis; and a word that is slidably connected to the dial 1 A code connection assembly, the character code connection assembly includes a blocking piece 3a located in the installation groove 1a, an elastic member 3b is arranged between the blocking piece 3a and the bottom of the installation groove 1a, and is located under the dial 1 The code block 3c on the side, and the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com