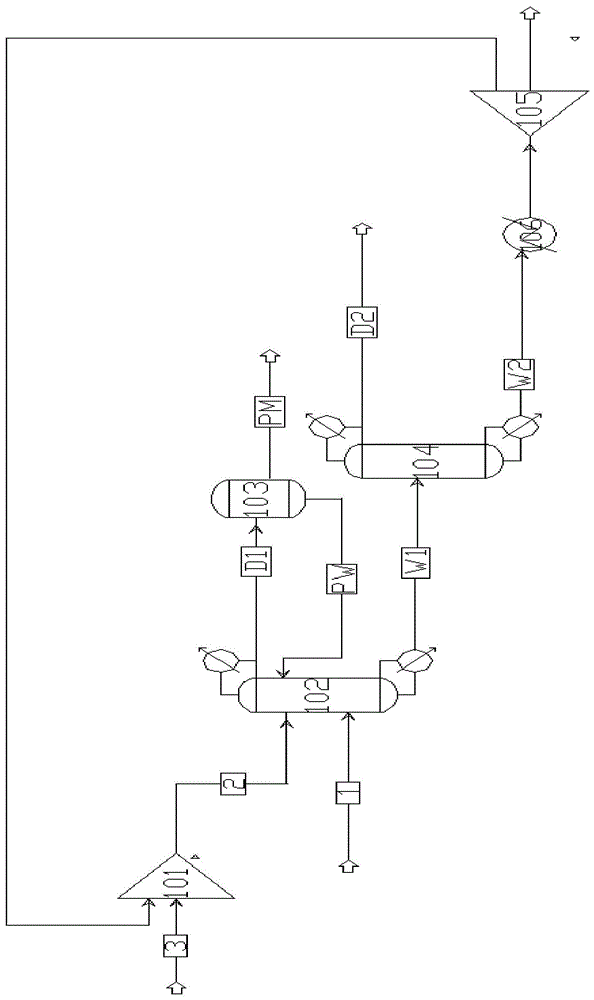

Extractive distillation process of methanol, dichloromethane and water

A technology of dichloromethane and process methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of complicated separation process, inability to realize continuous operation, cumbersome control, etc., and achieve high product purity , Significant practicability and economic benefits, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The massfraction of dichloromethane, methyl alcohol and water in the raw material liquid is 60%, 35%, 5% respectively, and the feed rate is 10000kg / h, and the temperature entering the extractive distillation tower is 25°C; 0.34 times of the feed amount, the feed temperature is 25°C, enter the extractive distillation tower operated at normal pressure for rectification, the reflux ratio of the extractive distillation tower is 1, the tower top temperature is 36°C, and the tower bottom temperature is 79°C . The high-purity dichloromethane mixed liquid (the mass fraction of dichloromethane is 95%) flowing out from the top of the tower is separated in a phase separator under normal pressure at 25° C. to obtain 99.8% of dichloromethane by mass fraction. The methanol rectification tower rectifies the mixture of methanol and water under normal pressure, the top of the tower obtains methanol with a mass fraction of 99.9%, and the bottom of the tower obtains water with a mass frac...

Embodiment 2

[0051] The massfraction of dichloromethane, methyl alcohol and water in the raw material liquid is 70%, 25%, 5% respectively, and the feed rate is 8000kg / h, and the temperature entering the extractive distillation tower is 20 DEG C; 1 times of feed amount, feed temperature is 20 ℃, and flow rate is 4000kg / h, enters the extractive distillation column rectification of normal pressure operation, and the reflux ratio of described extractive distillation column is 0.3, and tower top temperature is 40 ℃, The temperature in the bottom of the tower was 84°C. The high-purity dichloromethane mixed liquid (the mass fraction of dichloromethane is 99%) flowing out from the top of the tower was separated in a phase separator under normal pressure at 20° C. to obtain 99.81% of dichloromethane in mass fraction. The methanol rectification tower rectifies the mixture of methanol and water under normal pressure, the top of the tower obtains methanol with a mass fraction of 99.88%, and the bottom...

Embodiment 3

[0053] The mass fractions of dichloromethane, methanol and water in the raw material liquid are 70%, 22%, and 8% respectively, the feed rate is 10000kg / h, and the temperature entering the extractive distillation tower is 30°C; the quality of the extractant is the raw material liquid 0.6 times of the feed amount, the feed temperature is 30°C, the flow rate is 5200kg / h, enter the extractive distillation tower operated at normal pressure for rectification, the reflux ratio of the extractive distillation tower is 1.5, and the tower top temperature is 34°C , the temperature of the tower kettle was 77°C. The high-purity dichloromethane mixed liquid (95% mass fraction of dichloromethane) flowing out from the top of the tower was separated in a phase separator under normal pressure at 30° C. to obtain 99.76% mass fraction of dichloromethane. The methanol rectification tower rectifies the mixture of methanol and water under normal pressure, the top of the tower obtains methanol with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com