Toilet floor heating waterproof construction method and toilet floor heating waterproof system

A construction method and toilet technology, which are applied in the field of bathroom floor heating and waterproof construction methods and waterproof systems, can solve problems such as leakage, and achieve the effects of prolonging service life, improving waterproof performance and enhancing heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] One embodiment of the present invention provides a bathroom ground heating waterproof construction method, comprising the following steps:

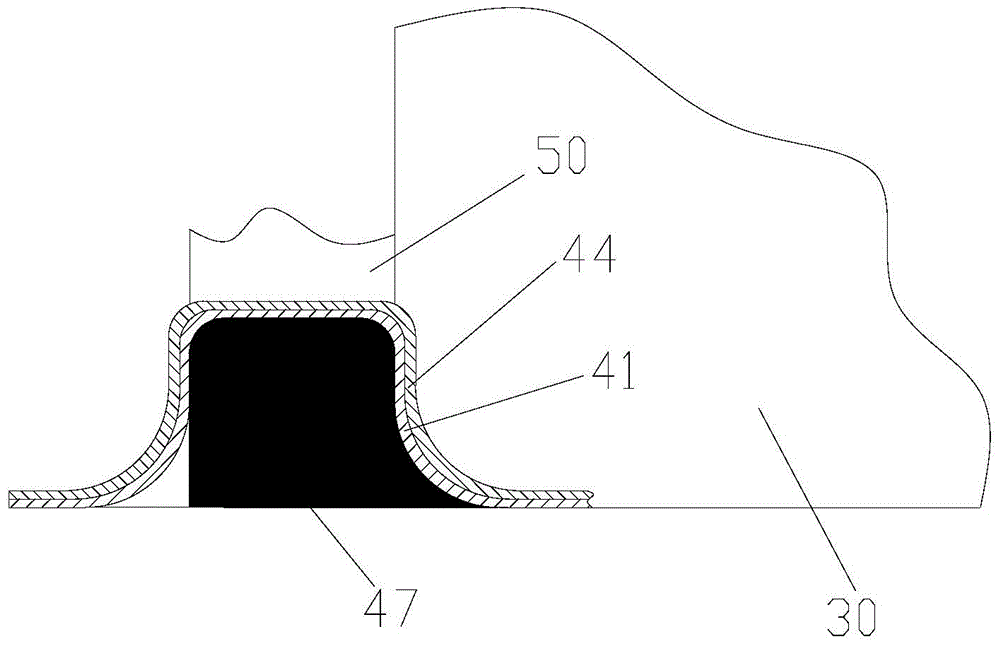

[0044] S1: if figure 1 As shown, the water-stop threshold 47 is set at the doorway 50 of the toilet, and the water-stop threshold 47 can be formed by concrete stacking, and plastering is done 30mm circular arc on the side that is positioned at the toilet.

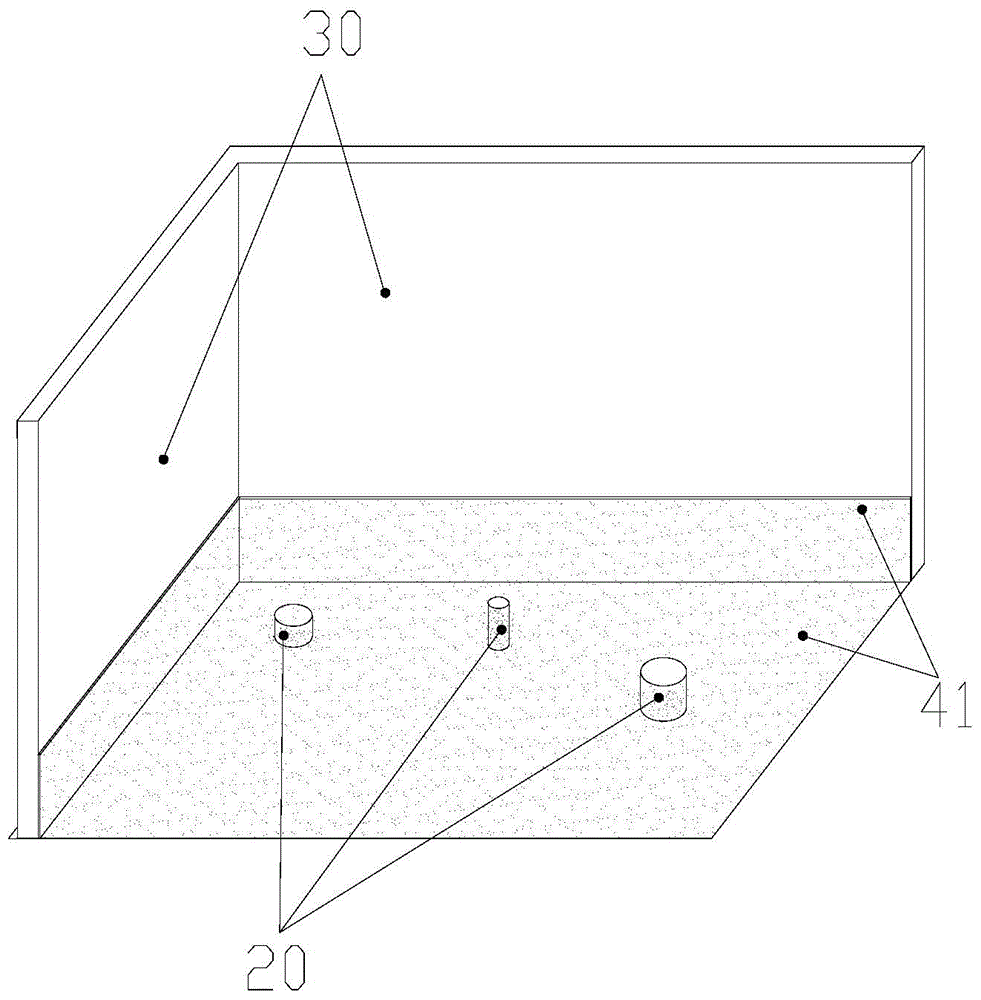

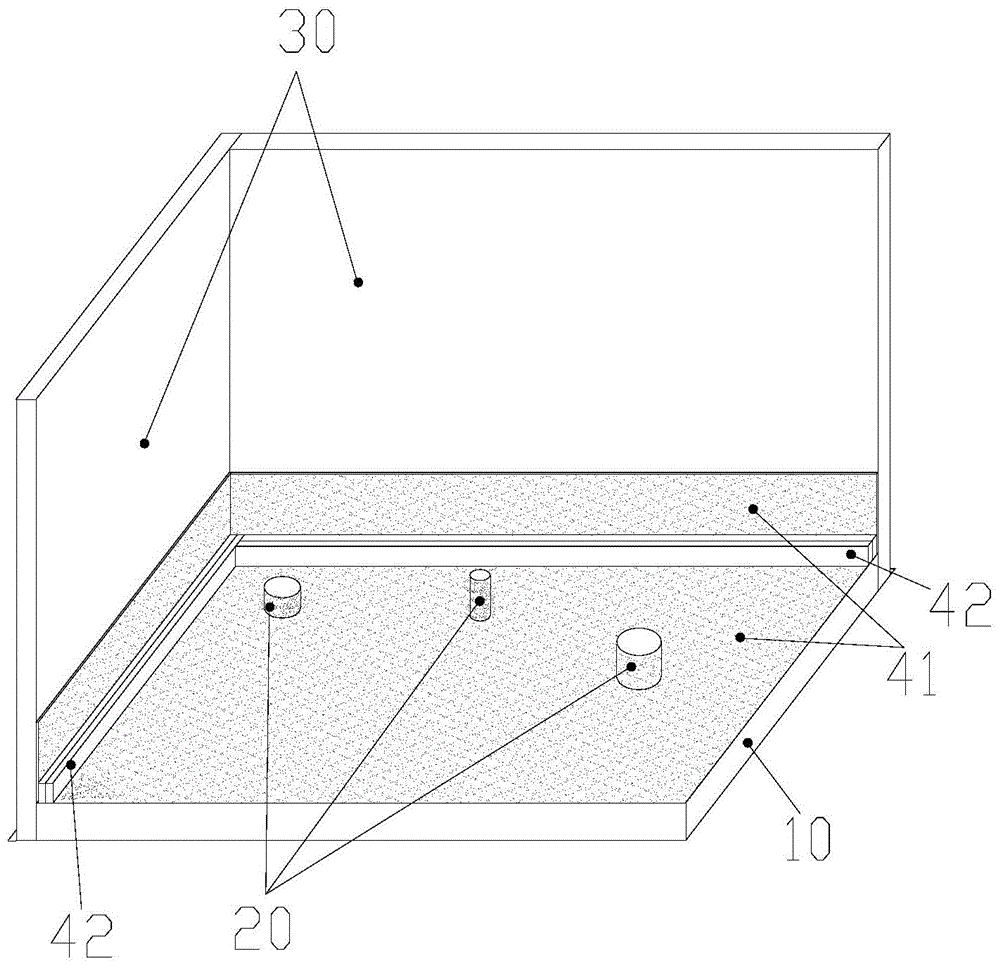

[0045] S2: if figure 2 As shown, the first waterproof layer 41 is laid on the structural basis, so that the first waterproof layer 41 is from the structural foundation to the surrounding wall 30, the water-stop threshold 47, and a plurality of water shedding such as shower bases, washbasins, and toilets. The outer walls of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com