Welding assistant column

A technology of welding pillars and pillars, which is applied in the direction of pillars, pier pillars, pillars, etc., can solve the problems of poor earthquake resistance, poor joint strength, complex process, etc., and achieve the effect of improving safety reliability and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

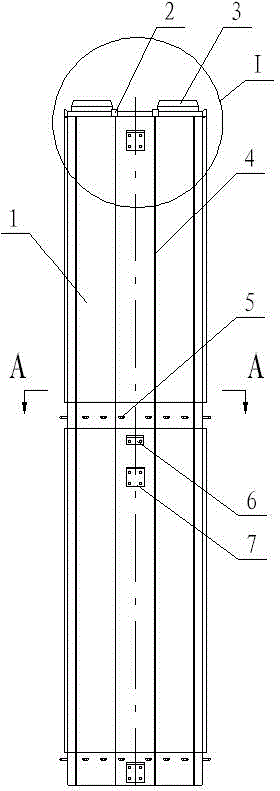

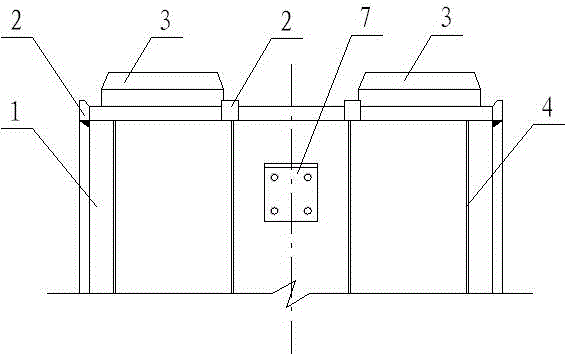

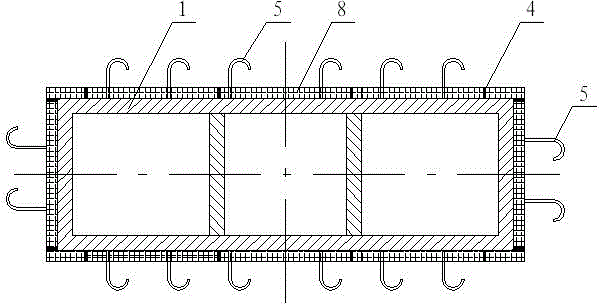

[0012] Such as figure 1 , figure 2 , image 3 As shown in the figure, there is a kind of helper column, the column body 1 adopts a closed box-shaped structure formed by welding steel plates, and the shape of the column is any one of rectangle, T-shape, X-shape or L-shape. The box structure is used to facilitate the connection of components such as square floor slabs or girders with the column body 1 . The shape of the column is rectangular, T-shaped, X-shaped or L-shaped, which is to facilitate the installation of the welding post in different positions, and to connect with other components better and faster.

[0013] The outside of the upper end of the column body 1 of the welding post is previously welded with a welding plate 2 in the factory, and the welding plate 2 is used for guiding, improving strength and helping positioning. The inner side of the upper end of the column body 1 is provided with a column core head 3, the column core head 3 is made of a steel plate or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com