Atomizing device and foam discharging starting atomization water discharging gas recovery method thereof

An atomization device and core tube technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of unsatisfactory atomization drainage effect, unreliable anchoring, and difficulty in salvage, etc., and achieve enhanced fogging. The effect of chemical drainage and gas recovery, recovery of bottom hole energy, and smooth salvage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

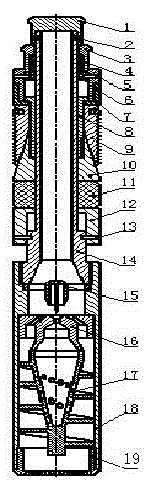

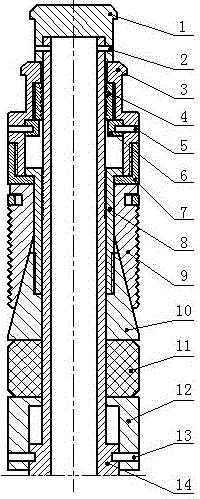

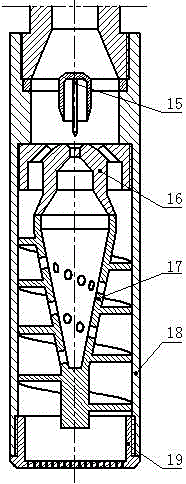

[0040] This embodiment provides an atomization device 24, which can well solve the technical defects of the existing atomization device such as difficulty in fishing, unreliable anchoring and unsatisfactory atomization and drainage effects. The structural features of the atomizing device 24 are as figure 1 , figure 2 and image 3 As shown, the feeding head 1, the first pin 2, the fishing head 3, the lock ring 4, the second pin 5, the shear ring 6, the slip seat 7, the suspension sleeve 8, the slip 9, the cone 10, the rubber tube 11. The pressure bearing sleeve 12, the third pin 13, the core tube 14, the resonator 15, the nozzle 16, the cyclone 17, the outer cylinder 18, the sand filter cylinder 19 and other components.

[0041] The delivery head 1 is fixedly connected to the upper end of the core tube 14 through the first pin 2 . The fishing head 3 is installed under the delivery head 1 . The lock ring 4 and the shear ring 6 are placed in the gap between the core tube 14 ...

Embodiment 2

[0050] Combining the structural features of the above-mentioned atomization device 24 and the working principle of using the atomization device 24 to realize deep atomization drainage and gas recovery with foam row activation, the construction process of drainage gas recovery will be described according to the construction sequence.

[0051] (1) Putting and setting the atomization device

[0052] The atomizing device 24 is lowered from the oil pipe 21 in the well with a steel wire. When lowering, the slip 9 slides down the cone 10 and opens to contact with the inner wall of the oil pipe 21 due to gravity. After lowering to the design position below the effusion liquid level 22, the steel wire is lifted, and the slips 9 are locked on the inner wall of the oil pipe 21. Continue to lift the steel wire, cut off the third pin 13, the core tube 14 drives the parts below the resonator 15 to go up, the inner horse tooth buckle of the lock ring 4 and the outer horse tooth buckle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com