Pipeline thermal insulation tube case

A pipe insulation and tube shell technology, which is applied in the direction of pipeline protection, heat preservation, and pipeline protection through heat insulation, etc., can solve the problems of affecting heat preservation effect, increasing production cost, poor heat preservation effect, etc. The effect of low resource and construction operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The present invention will be further described below with reference to the accompanying drawings.

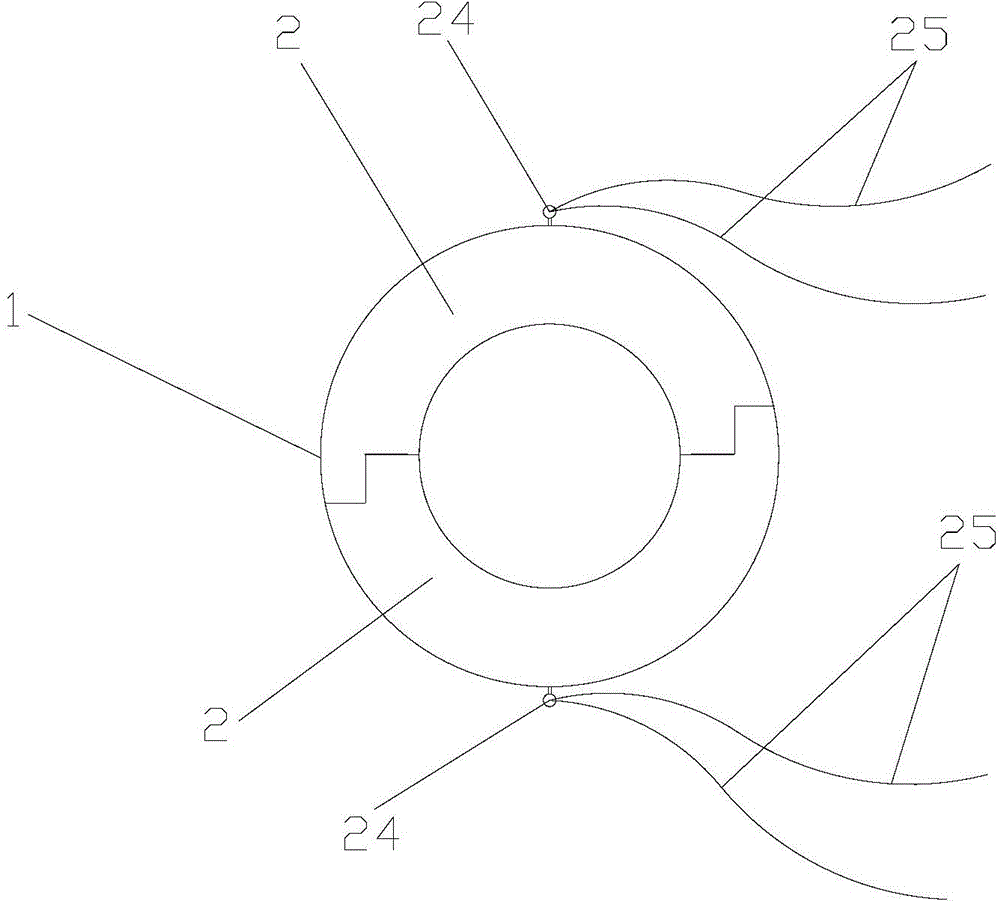

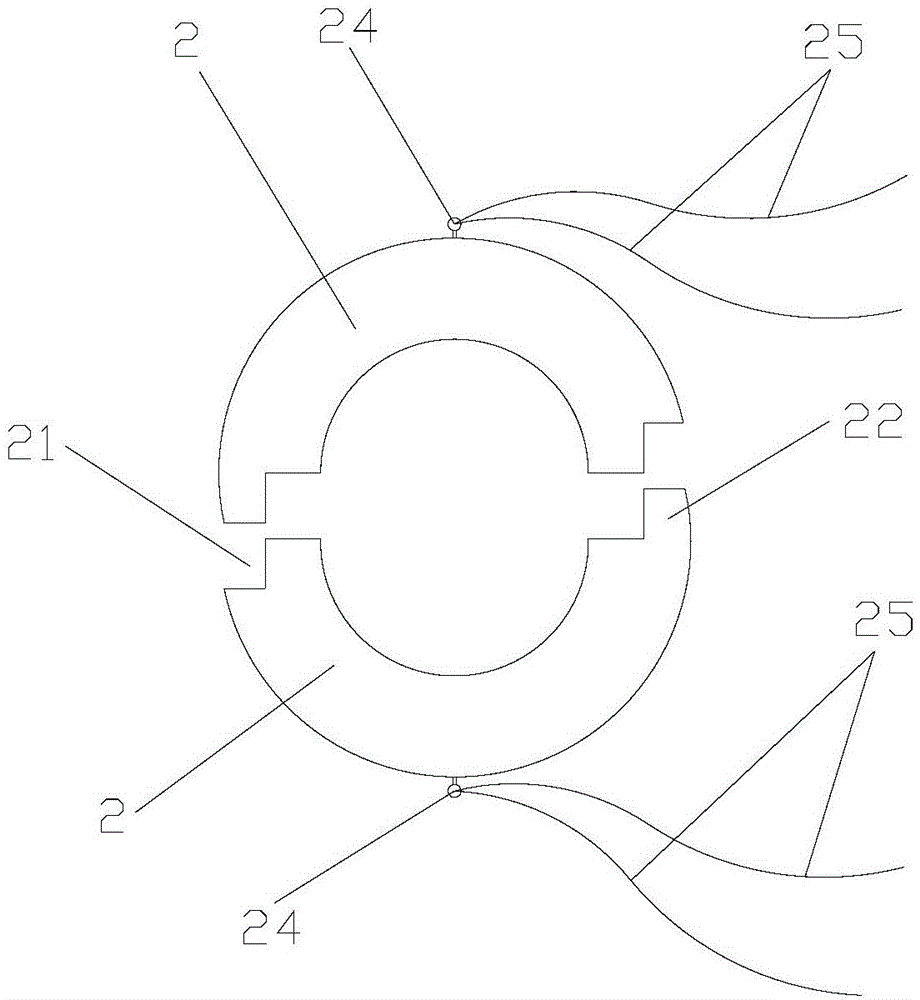

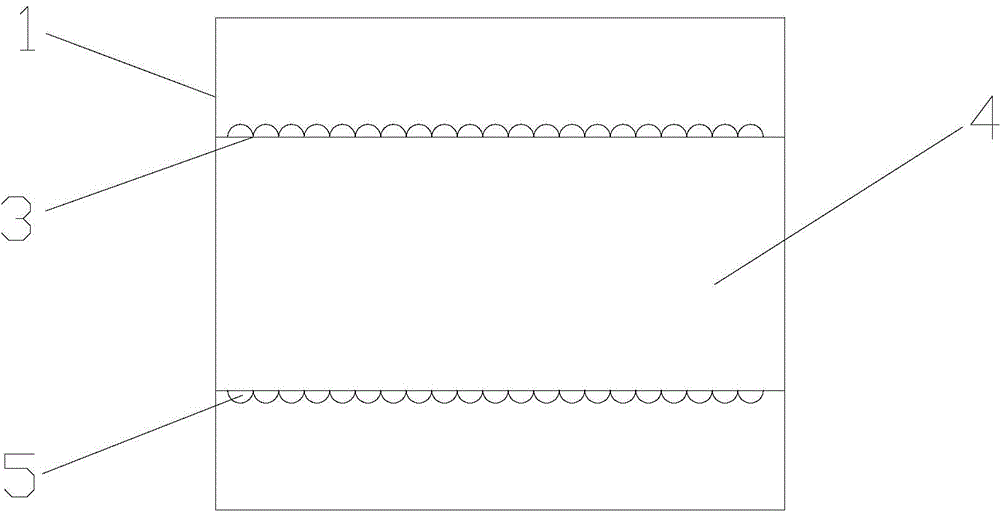

[0029] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a pipe insulation shell includes a shell body 1 with a hollow cylindrical structure, the shell body 1 includes two half shells 2 with the same structure, and the inner surface 3 of the half shell 2 is a shaft The outer end of one end surface of the half shell 2 is provided with a groove 21, and the outer end of the other end surface of the half shell 2 is provided with a convex step 22.

[0030] Wherein, the groove bottom plane of the groove 21 is provided with a tooth-like pattern 23 for filling glue; the step top plane of the convex step 22 is also provided with a tooth-like pattern 23 for filling the glue; The toothed pattern 23 at the bottom of the groove 21 is filled with glue and sealed with adhesive tape; the toothed pattern 23 at the top of the convex step 22 is also filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com