A compound control method and device for the temperature of crude oil heating furnace

A crude oil heating furnace and composite control technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as failure to achieve production goals, and achieve the effect of improving economic and social benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

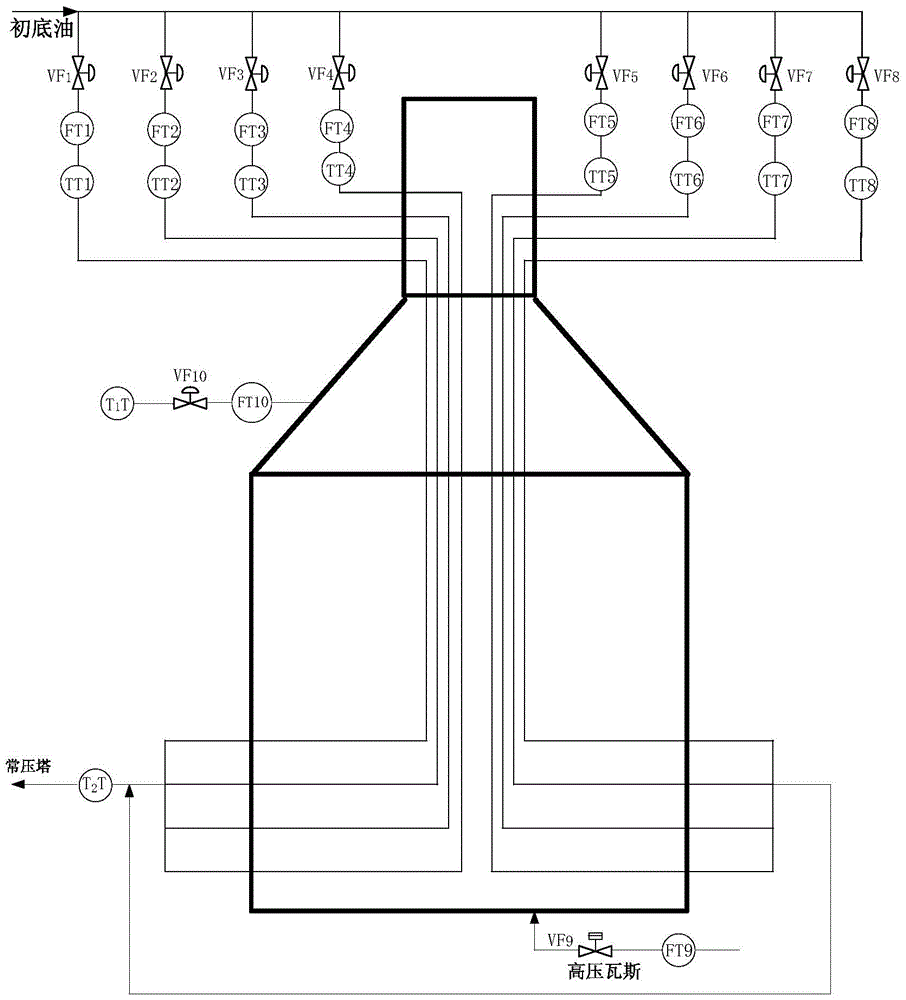

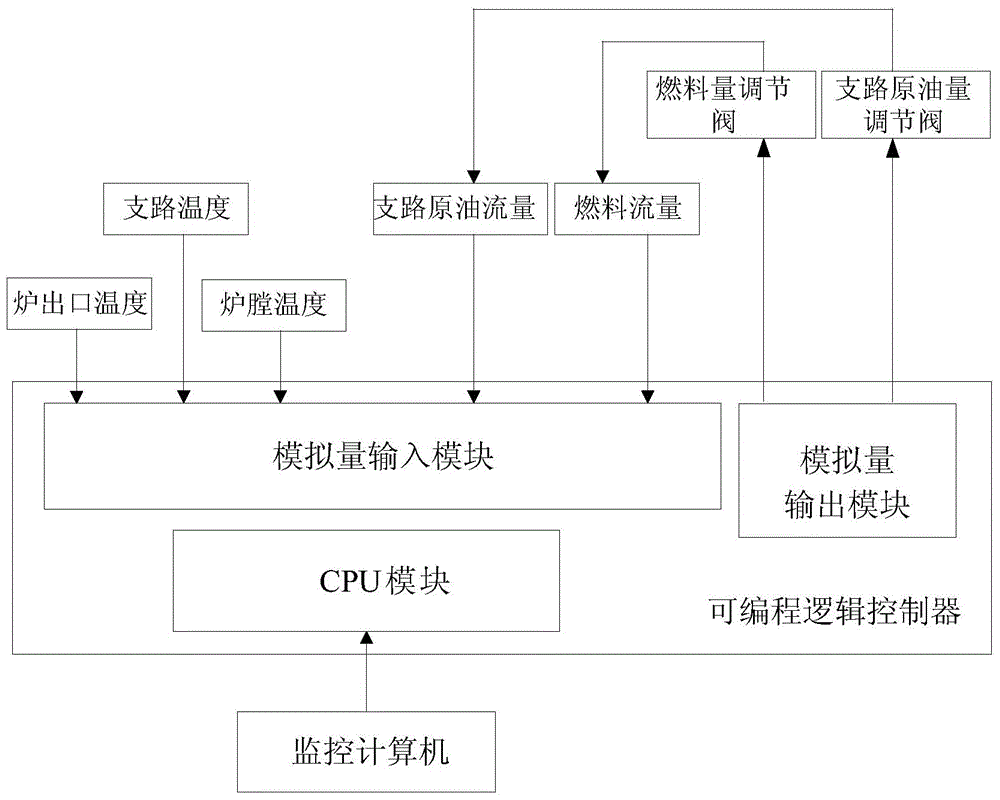

[0036] Take the crude oil heating furnace of a certain enterprise as an example, such as figure 1 As shown, the material from the initial distillation tower is divided into 8 channels and enters the heating furnace for heating. The original control scheme of the enterprise is a cascade control of the furnace temperature and the furnace outlet temperature. The fluctuation range of the furnace outlet temperature is ±2°C. The temperature deviation between them can reach about 10°C at most; the over-vaporization rate is required to be 1-3%, and the over-vaporization rate measured on site sometimes exceeds 4%. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com