Refrigerator illumination structure and assembly positioning method of refrigerator illumination structure

A technology for lighting structures and refrigerators, which is applied to lighting devices, lighting and heating equipment, household refrigeration devices, etc. It can solve problems such as difficult assembly, reduced assembly efficiency, and positional deviation of lampshades, so as to reduce production costs and ensure relative accuracy. , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

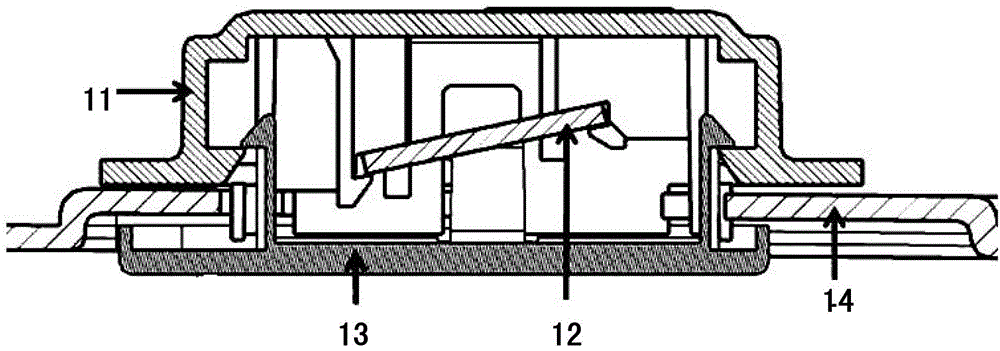

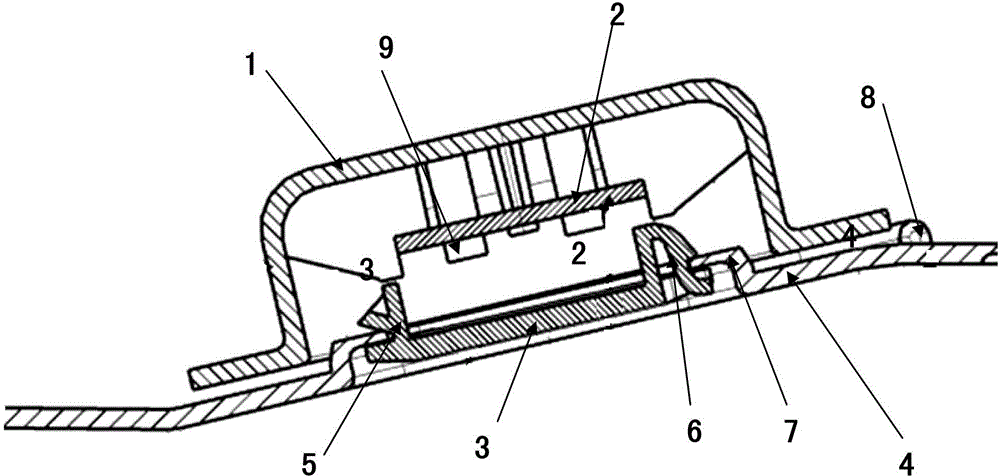

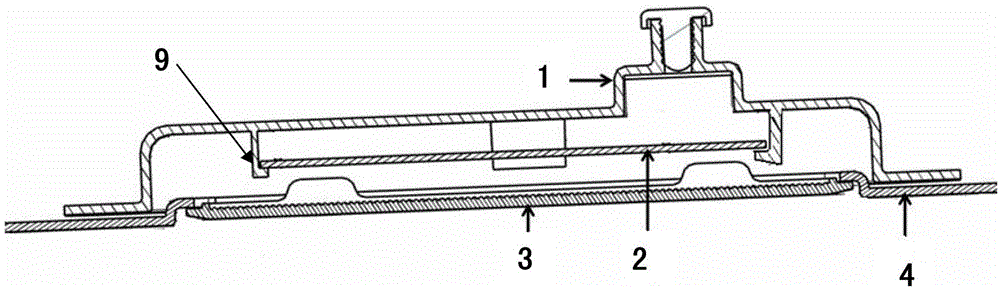

[0032] Please also see Figure 2 to Figure 5 , figure 2 It is a longitudinal sectional view of a refrigerator lighting structure disclosed by the present invention. image 3 It is a transverse sectional view of a refrigerator lighting structure disclosed by the present invention. Figure 4 It is a structural schematic diagram of a lampshade in a refrigerator lighting structure disclosed by the present invention. Figure 5 It is a structural schematic diagram of fixing the pre-embedded box and the positioning rib in a refrigerator lighting structure disclosed by the present invention. As shown in the figure, a refrigerator lighting structure is set on the inner liner 4 of the refrigerator. The lampshade 3 and the embedded box 1 are fixedly arranged on the inner container 4, and the lampshade 3 and the inner container 4 are connected and fixed.

[0033] By connecting and fixing the lampshade 3 and the inner container 4, there is no direct assembly relationship between the l...

Embodiment 2

[0046]The rest is the same as that of Embodiment 1, except that the hooks on both sides of the lampshade 3 are elastic hooks 6, which facilitates the assembly and disassembly of the lampshade.

Embodiment 3

[0048] The rest are the same as in Embodiment 1, except that the lampshade 3 can be directly fixed on the lower side of the inner container, the lampshade and the embedded box are respectively arranged on both sides of the inner container, and the embedded box and the lampshade are indirectly fixed through the inner container. Avoid the problem that the lampshade cannot be assembled and cause the cabinet to be scrapped, and reduce the production cost.

[0049] The invention discloses a refrigerator lighting structure and an assembly and positioning method thereof. By connecting and fixing the lampshade and the inner container, there is no direct assembly relationship between the lampshade and the pre-embedded box, so the forming thickness of the inner container does not affect the assembly of the lampshade. Improve the assembly efficiency, avoid the problem that the lampshade cannot be assembled and cause the box to be scrapped, and reduce the production cost.

[0050] At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com