Measuring Method of Stress and Strain of Dedendum Root of Fixed Sun Gear of Planetary Gear System

A technology of fixed center and planetary gear train, applied in the direction of machine gear/transmission mechanism testing, measuring devices, instruments, etc., can solve the problems of many wiring harnesses, complicated installation, inconvenient on-site application, etc., to prevent electromagnetic interference, simple structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

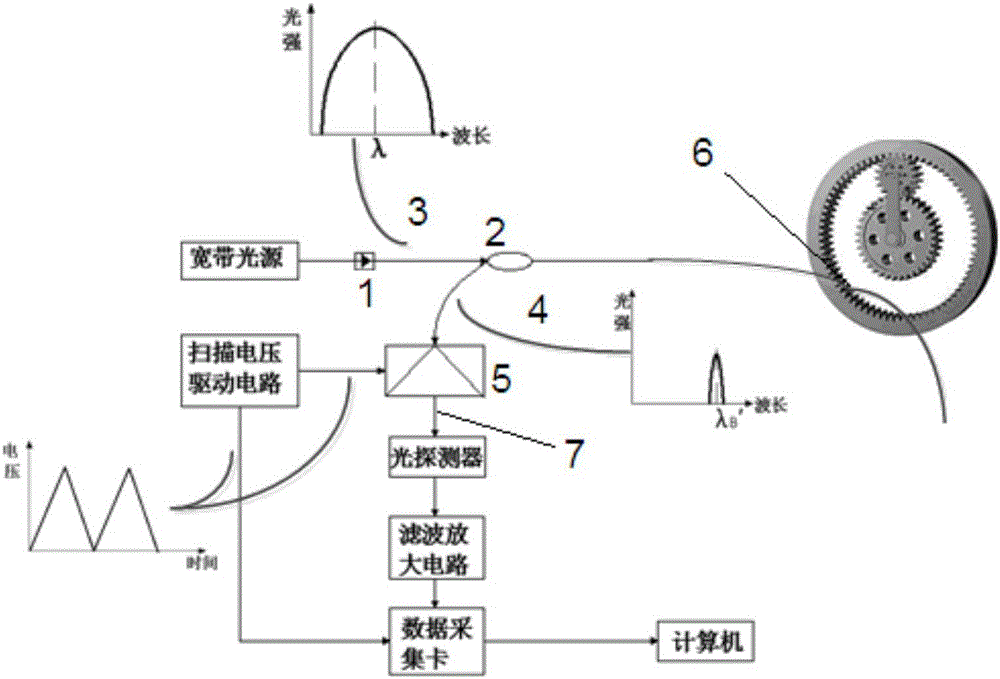

[0029] The Basic Principle of Measuring Stress with Fiber Bragg Grating

[0030] A fiber grating is composed of a core and a cladding. When broadband light is incident into the fiber grating, the incident light wave with a central wavelength that satisfies certain conditions will be reflected. This wavelength is called the Bragg wavelength. The expression for the Bragg wavelength is:

[0031] lambda B =2n eff Λ (1)

[0032] where n eff is the effective refractive index of the fiber core, and Λ is the grating pitch of the fiber grating.

[0033] When the fiber is subjected to axial stress, the grating pitch and refractive index change due to stretching and elastic-optic effects, which in turn causes the fiber Bragg wavelength to shift. The wavelength shift is:

[0034] Δλ B =(1-P e )ελ B (2)

[0035] Equation (2) is the stress sensing model of FBG, where P e is the effective elasto-optic coefficient, which can be obtained from the fiber parameters, and ε is the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com