PAR lamp fixed focus detection device and fixed focus detection method thereof

A detection device and detection method technology, applied in the direction of measurement device, optical instrument test, machine/structural component test, etc., can solve the problem of unqualified fixed focus products cannot be reworked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The design will be further described below in conjunction with the accompanying drawings of the description.

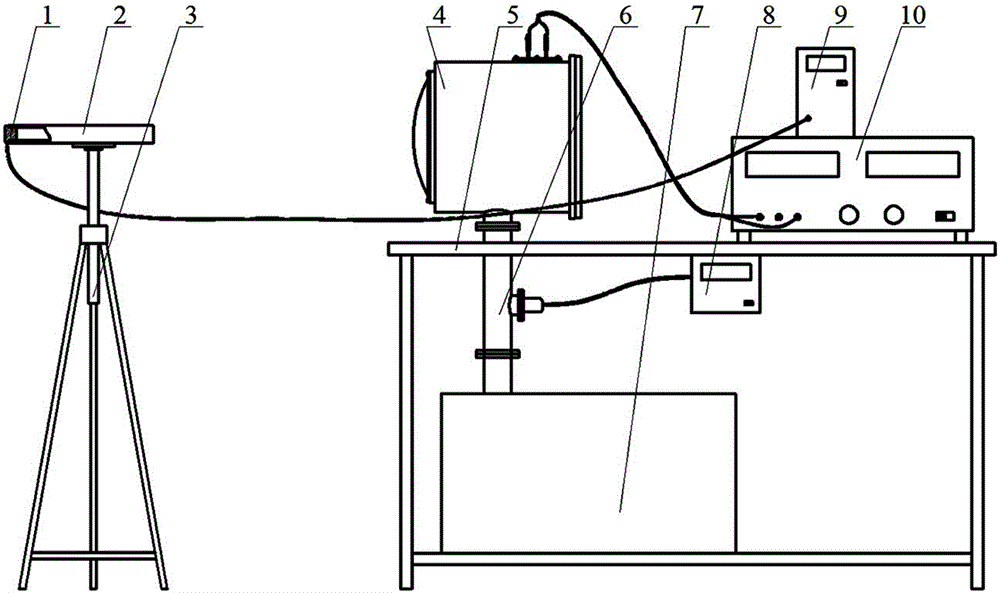

[0025] One, first set forth the composition of the fixed-focus detection device used in the present invention, including the following three aspects:

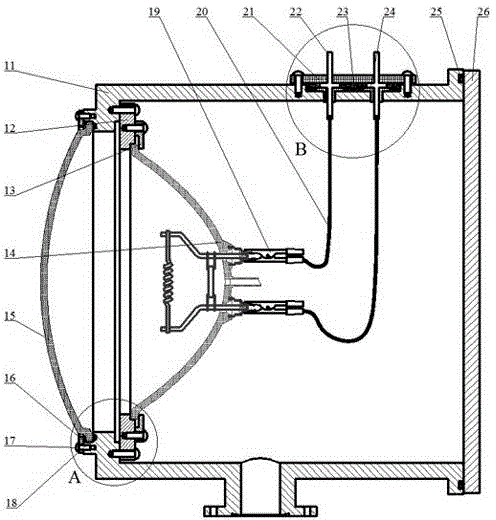

[0026] A, the assembly of vacuum test chamber 4

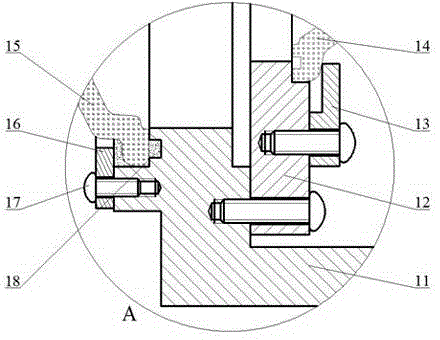

[0027] see Figure 2~Figure 4 , the vacuum test chamber 4 is composed of a test chamber body 11, a lamp mounting bracket 12, a lamp fixing bracket 13, a lamp assembly 14, a glass screen 15, a glass screen cover plate 16, screws 17, a glass screen sealing ring 18, an alligator clip 19, and a wire 20. Insulation cover plate 21, connection terminal 22, sealant 23, insulation sleeve 24, test cabin movable door 25, movable door sealing ring 26 constitute.

[0028] see figure 2 , the lamp mounting bracket 12 and the lamp fixing bracket 13 are used in conjunction with the lamp assembly 14, that is, according to the specifications of the lamp assembly 14 to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com