Enterprise field sheet material and section bar management method

A technology of on-site management and management methods, applied in the field of on-site management of sheets and profiles in enterprises, can solve problems such as hidden safety hazards, material waste, and error-prone on-site operations, and achieve the effects of improving timeliness, improving management efficiency, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

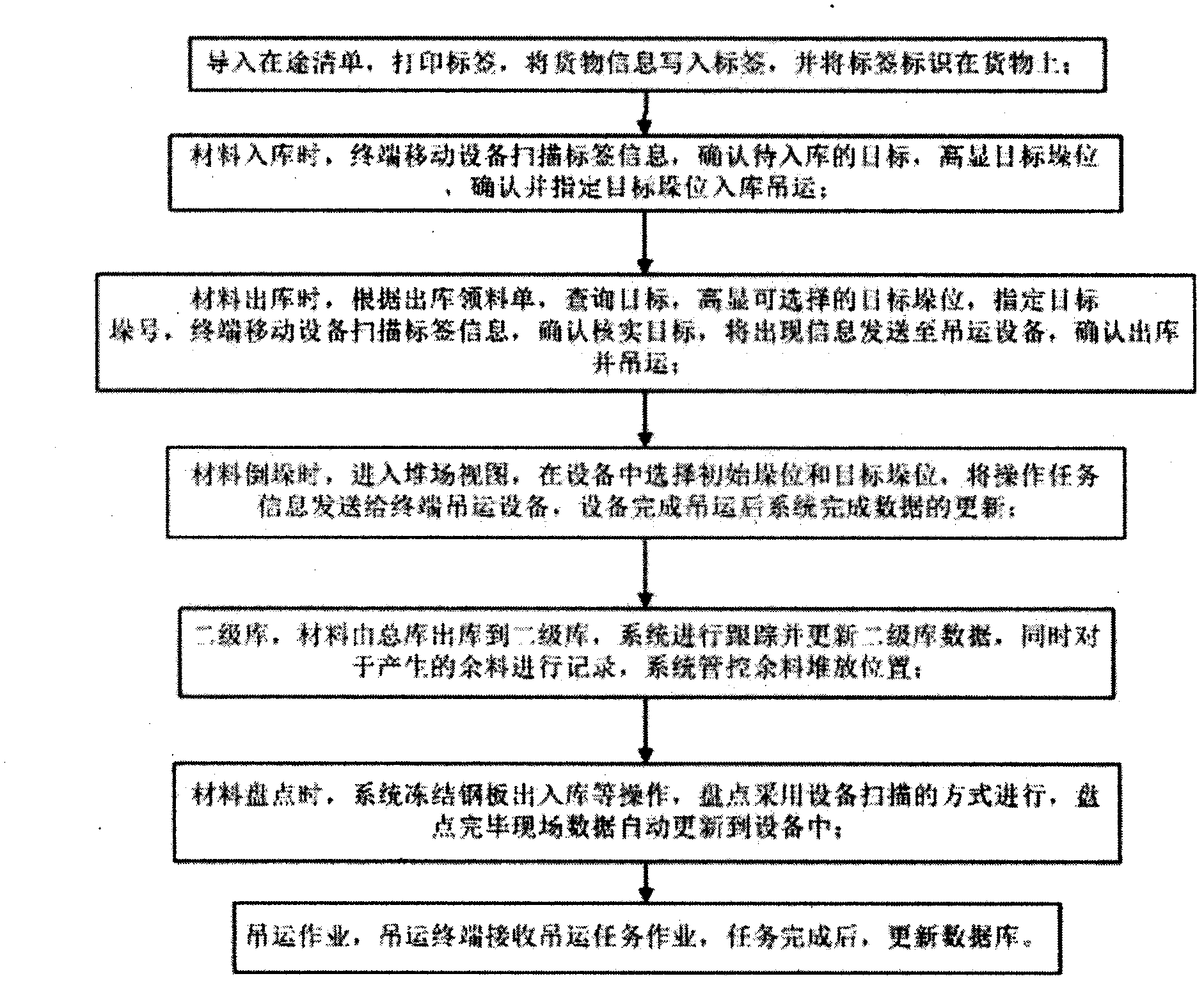

[0029] The embodiment of the present invention provides a management method for on-site management of plates and profiles in an enterprise, which can reduce steel inventory, improve the efficiency of steel storage and inventory, reduce enterprise logistics costs, and track the physical location of each piece of material on site.

[0030] The method for managing boards and profiles provided by the embodiments of the present invention on site will be described in detail below with reference to the accompanying drawings.

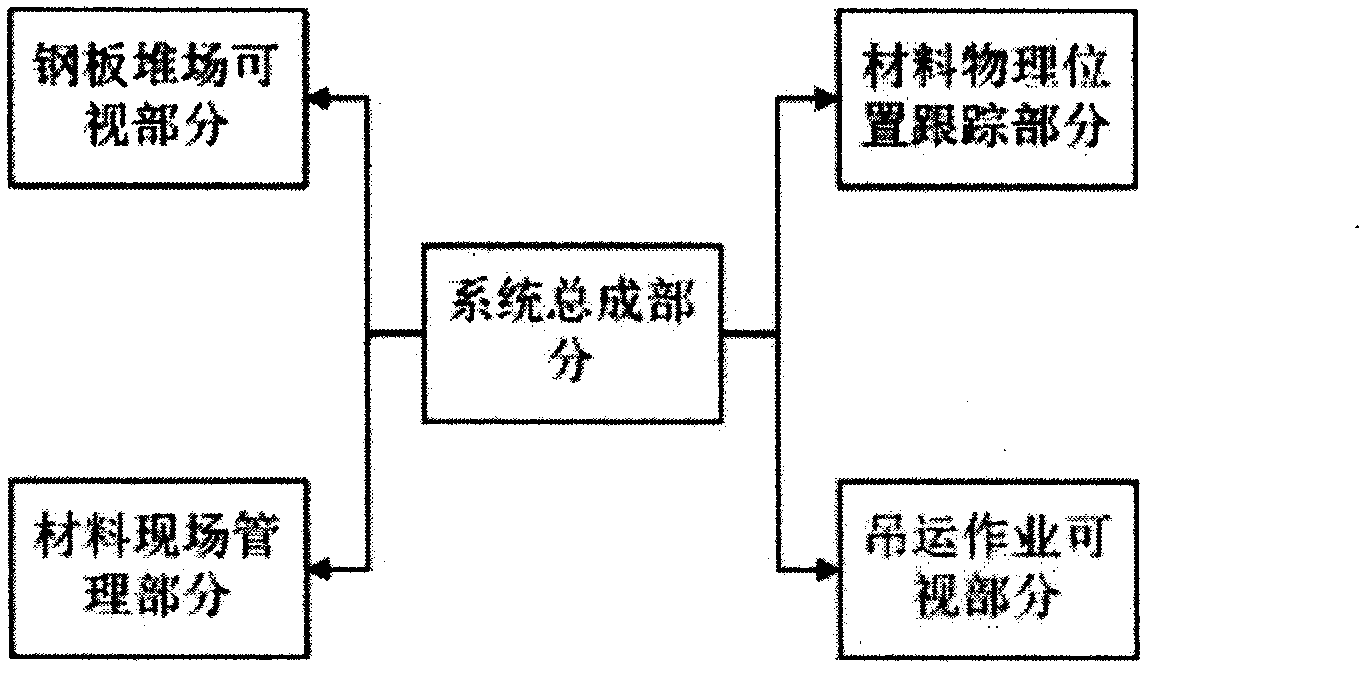

[0031] Such as figure 1 As shown, a management method for on-site management of plates and profiles provided by an embodiment of the present invention is characterized in that it includes a visible part of the steel plate stockyard, a material on-site management part, a material physical position tracking part, and a lifting operation controllable part. Visual parts and system assembly parts;

[0032] The visible part of the steel plate storage yard: the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com