Glue scraping equipment

A kind of equipment and glue removal technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as reduced success rate, scrapped workpieces, unstable quality of glue removal, etc., to maintain stability , reduce resistance and external force, improve success rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The implementation of the present invention is described below through specific specific examples. Those skilled in the art can easily understand other advantages and effects of the present invention from the specific structural features of the squeegee device disclosed in this example.

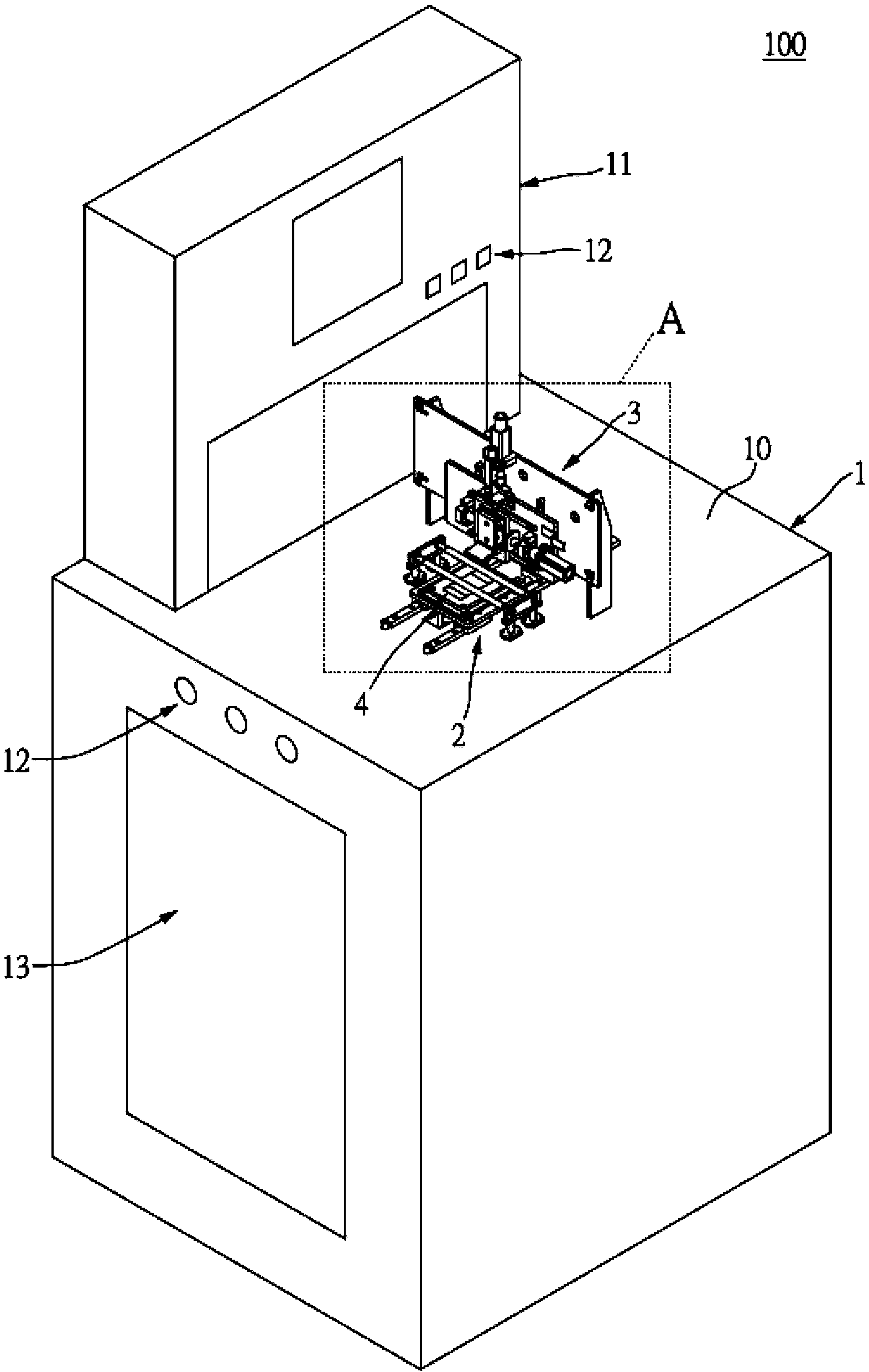

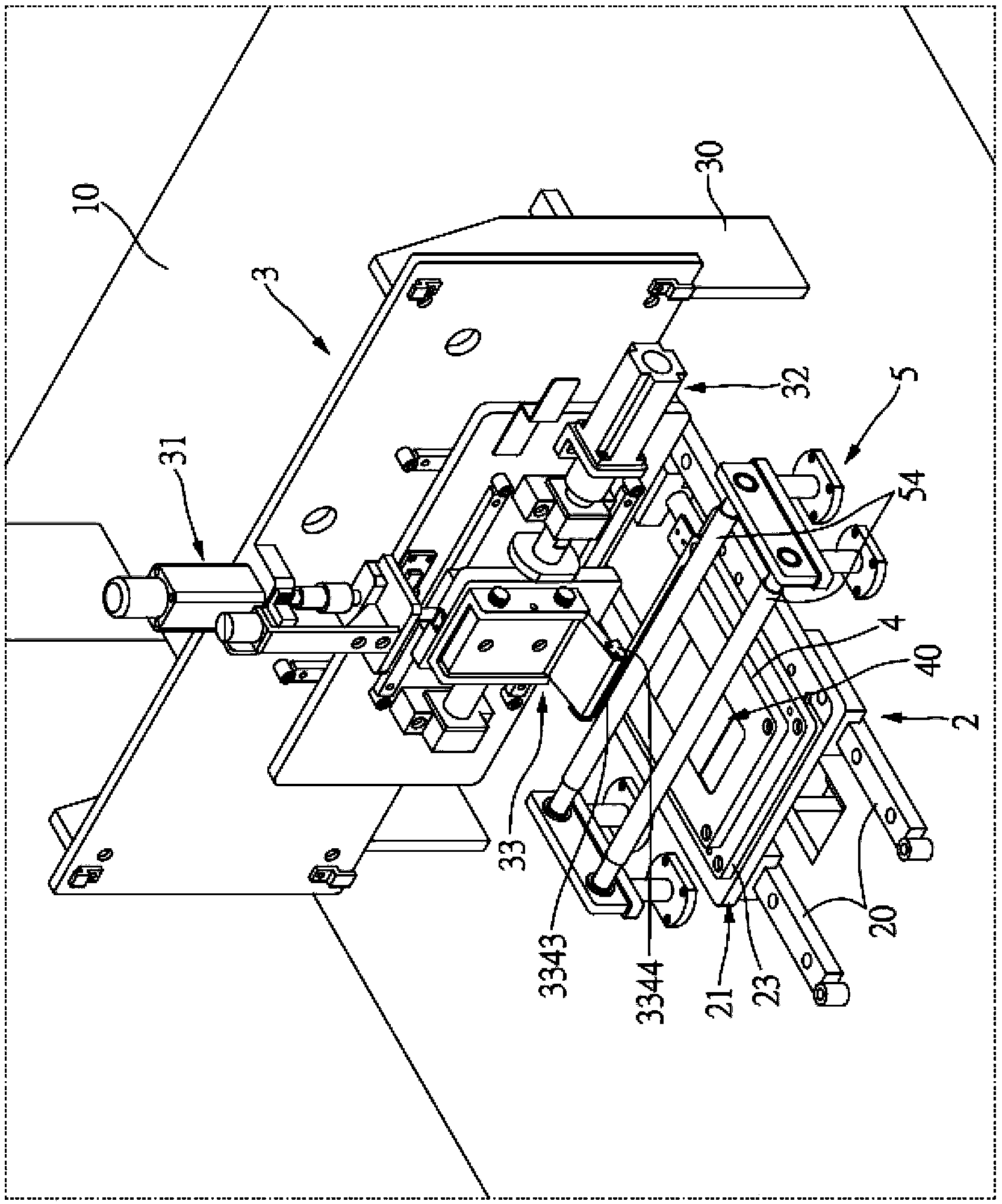

[0060] see figure 1 , which is a three-dimensional schematic view of the squeegee equipment of the present invention, the squeegee equipment 100 includes a machine body 1 , a linear displacement device 2 , a scraper transmission device 3 and a platform jig 4 .

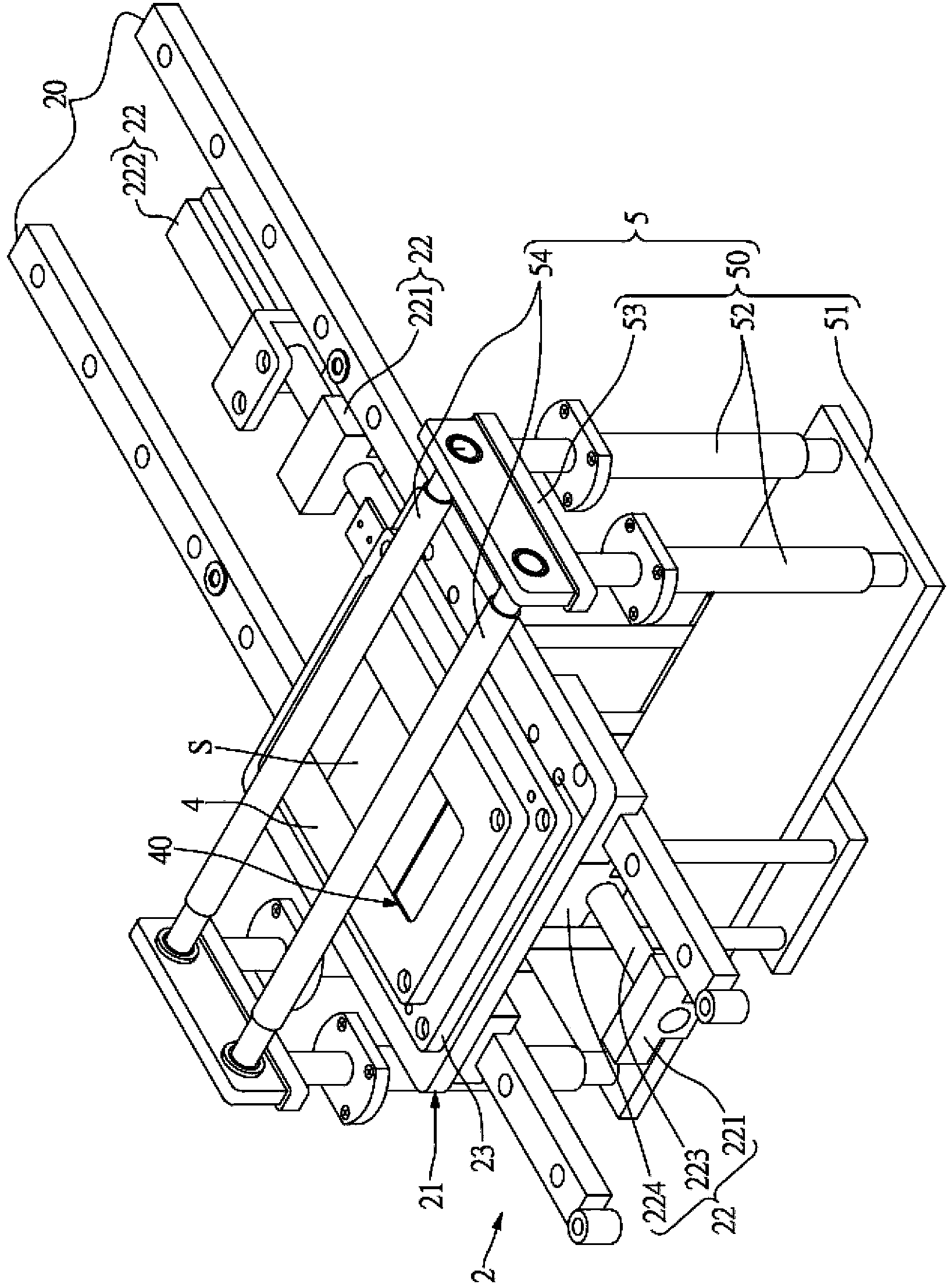

[0061] Among them, the scraper transmission device 3 is arranged on the body 1 and has a scraper assembly 33 that can move horizontally and vertically; the linear displacement device 2 is arranged on the body 1; the platform jig 4 is arranged on the linear displacement device 2 and can be linearly displaced The device 2 is driven to be displaced from one side of the scraper transmission device 3 to the other side.

[0062] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com