Million-kilowatt nuclear turbine pedestal plate finish milling processing method

A steam turbine and base frame technology, which is applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of base frame plate flatness and surface quality processing accuracy, and achieve the effect of eliminating tool marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

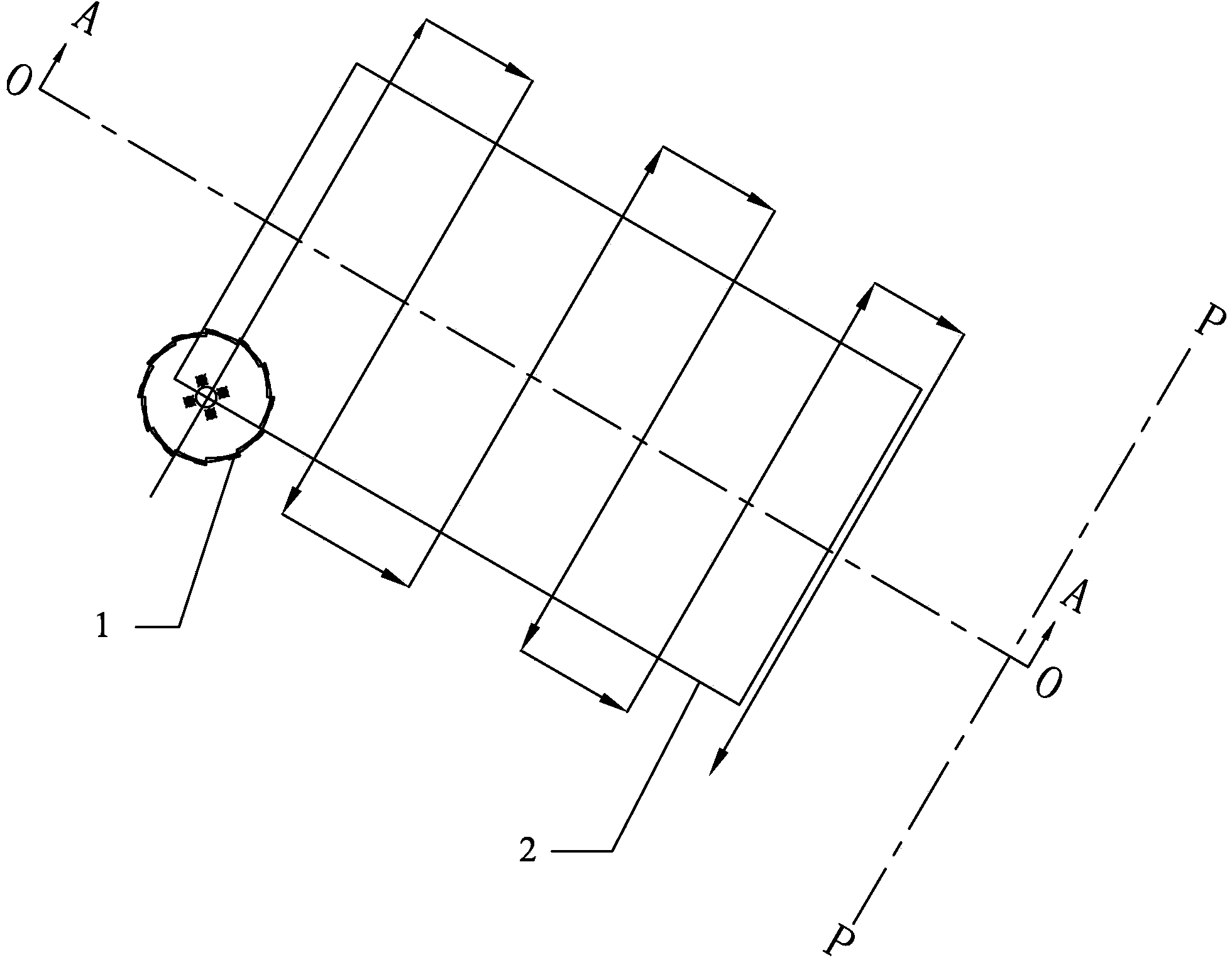

[0018] Specific implementation mode one: as figure 1 , figure 2 Shown, a kind of finishing milling processing method of the pedestal plate of a nuclear power steam turbine comprises the following steps:

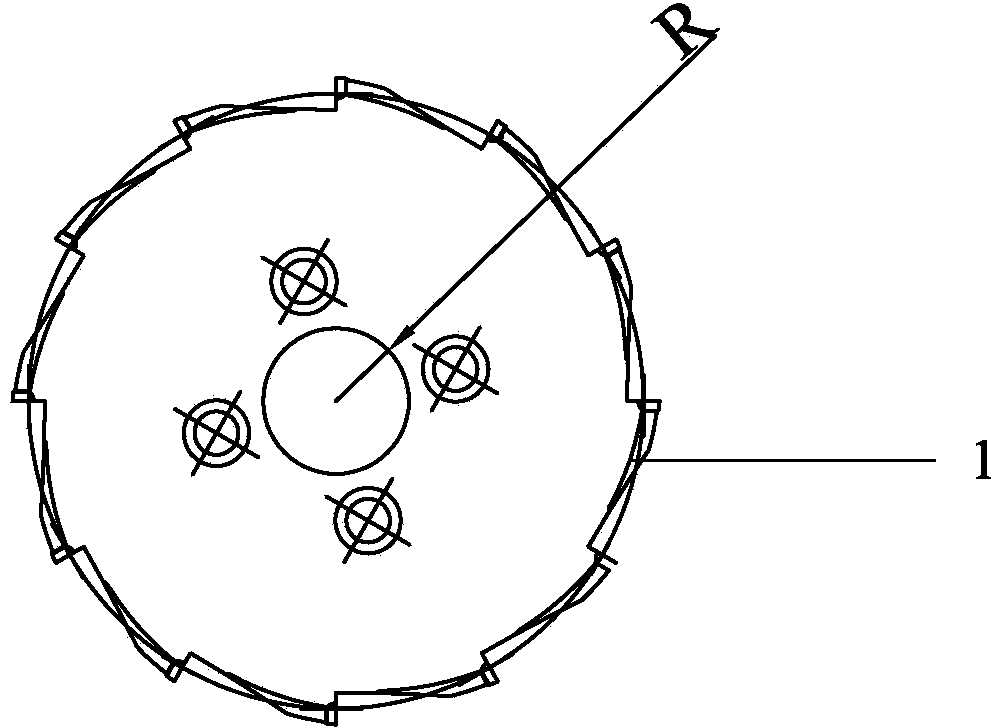

[0019] Step 1. Install the milling cutter disc 1 on the machine tool spindle, place a dial gauge on the machine tool table with the gauge head up, and point the center of the milling cutter disc without inserts to the gauge head;

[0020] Step 2, move the milling cutter disc 1 along the X axis (the X axis refers to figure 2 As shown, the center line of the base plate (in the direction of O-O) moves to the position R from the center of the milling cutter disc, where R is the radius of the cutter body of the milling cutter disc, and the milling cutter disc 1 is not rotated by circular interpolation. Walk a full circle trajectory with a radius of R in the state of the state, and determine the high point position and the low point position on the circumferential direction of ...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 5, the difference between the high point position and the low point position of the milling cutter after inserting the blade can be directly measured by a laser detection device.

specific Embodiment approach 3

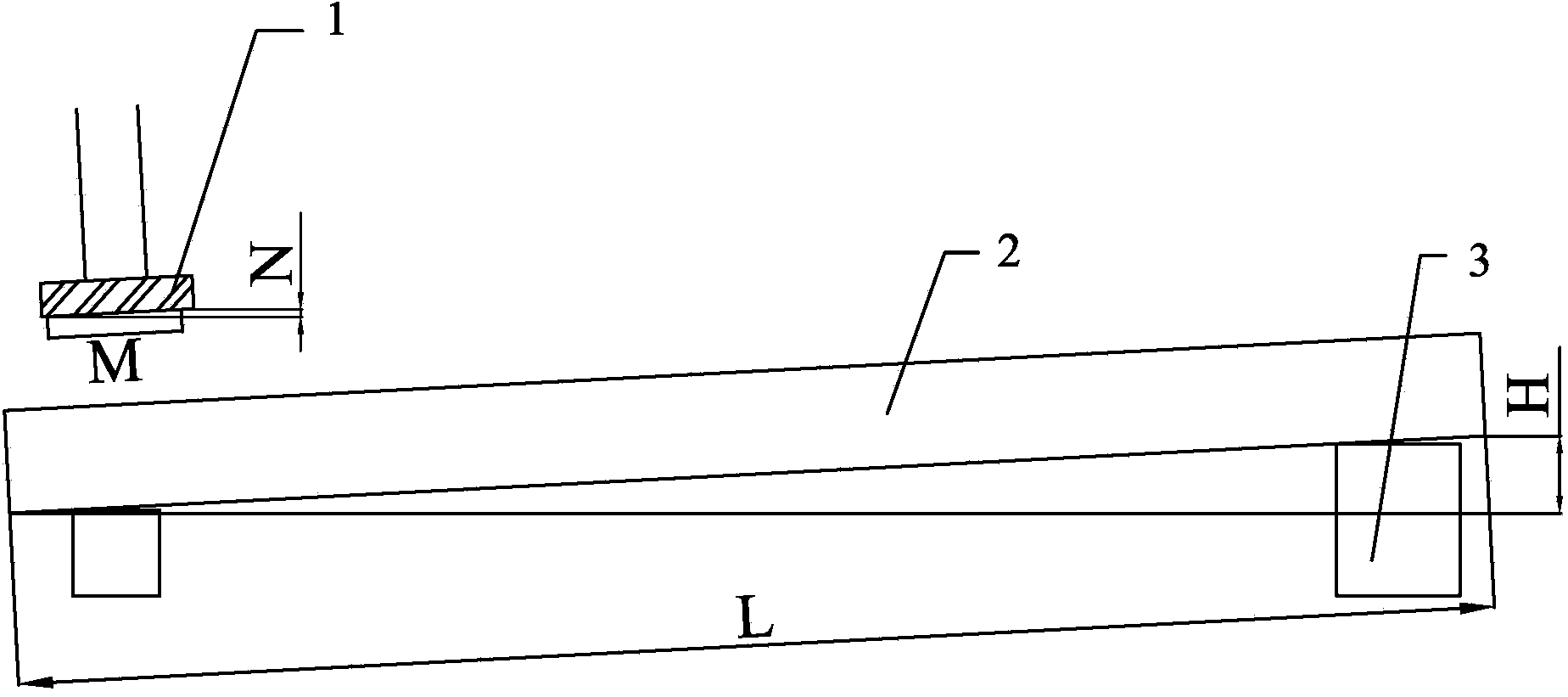

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step seven, when the step of receiving the knife appears at the junction of the two tool rails on the processing surface, use the spacer 3 to place the base plate 2 along the milling The direction of the line connecting the high point position and the low point position of the cutter head 1 is adjusted to a height parallel to the milling cutter head 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com