Slat conveyor

A technology for conveying devices and slats, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effects of preventing wear, reducing size, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In this specification, front, rear, left, and right are shown in a state facing the conveying direction F of the conveying path part T (from the upstream side to the downstream side), and a view viewed from the right is referred to as a front view.

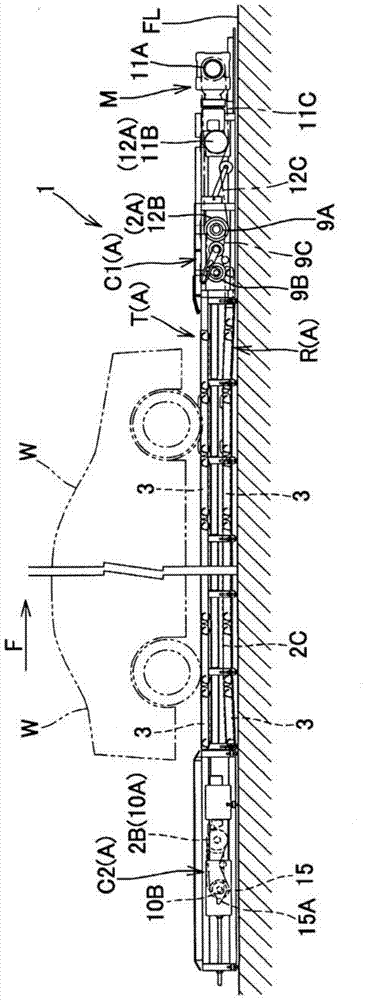

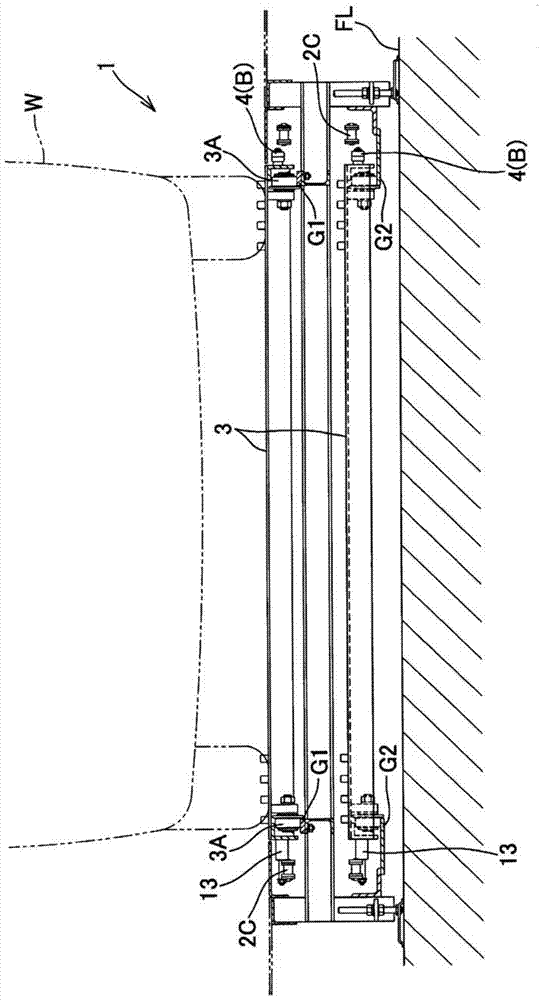

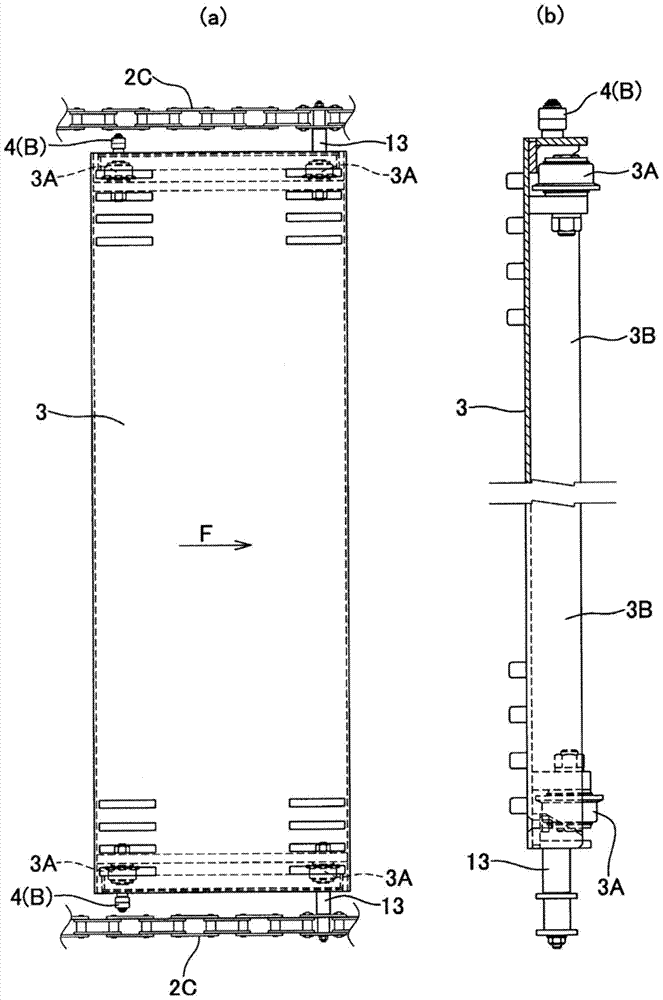

[0094] Such as figure 1 As shown in the front view of , the slat conveying device 1 according to the embodiment of the present invention has the route changing path part C1 passing through the downstream side of the conveying direction F and the route changing path part C2 passing through the upstream side of the conveying direction F. The vertical circulation path A connecting the ends of the upper and lower conveyance path T and the return path R passes through the endless chain stretched over the sprocket 2A on the downstream side in the conveying direction F and the sprocket 2B on the upstream side in the conveying direction F. 2C moves a plurality of slats 3, 3, ... while conveying the conveyed object W through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com