Rock-core drill holder

A technology of core drilling rigs and grippers, which is applied to drill pipes, drill pipes, drilling equipment, etc., and can solve the problems of time and manpower, cost, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

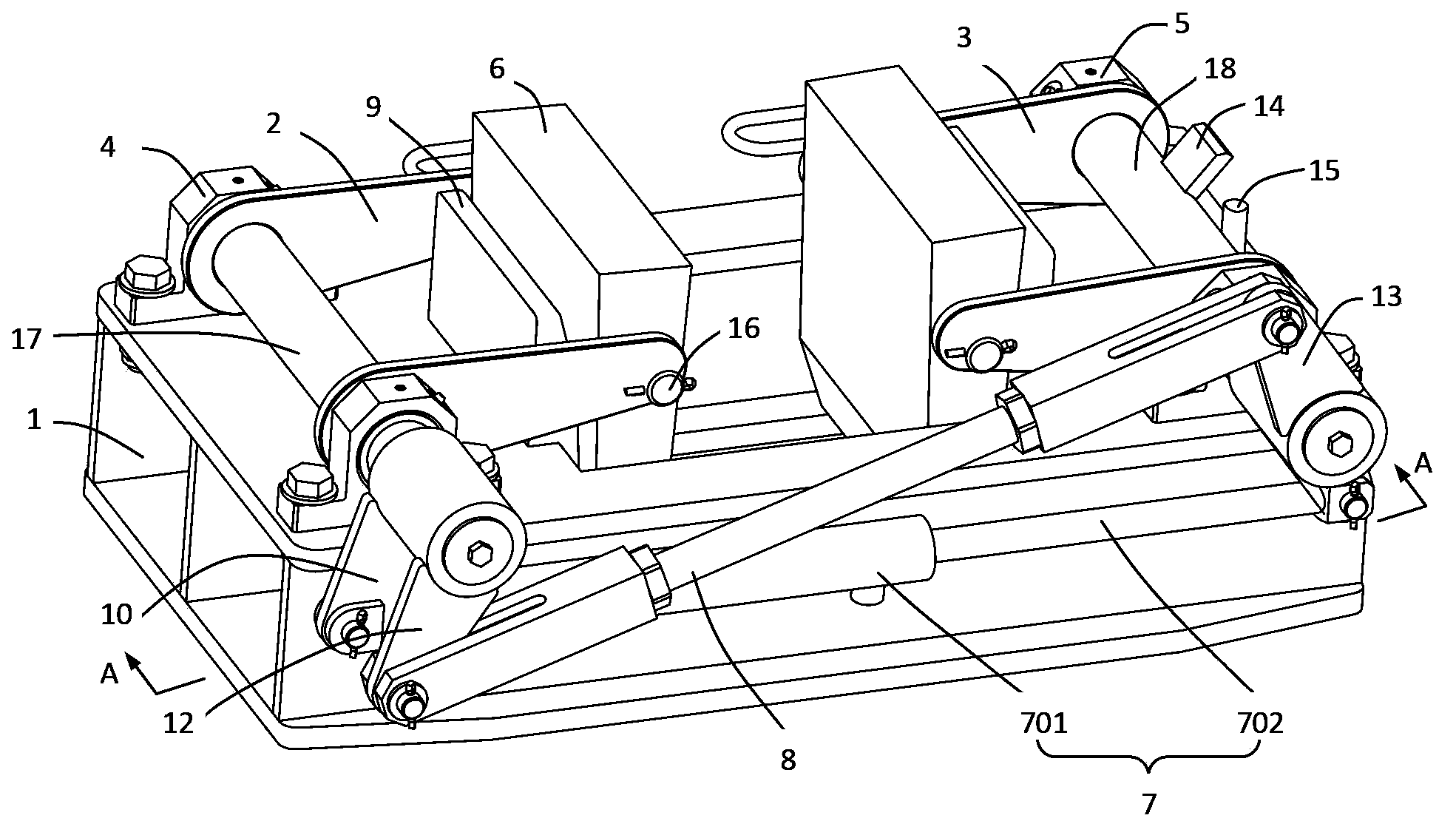

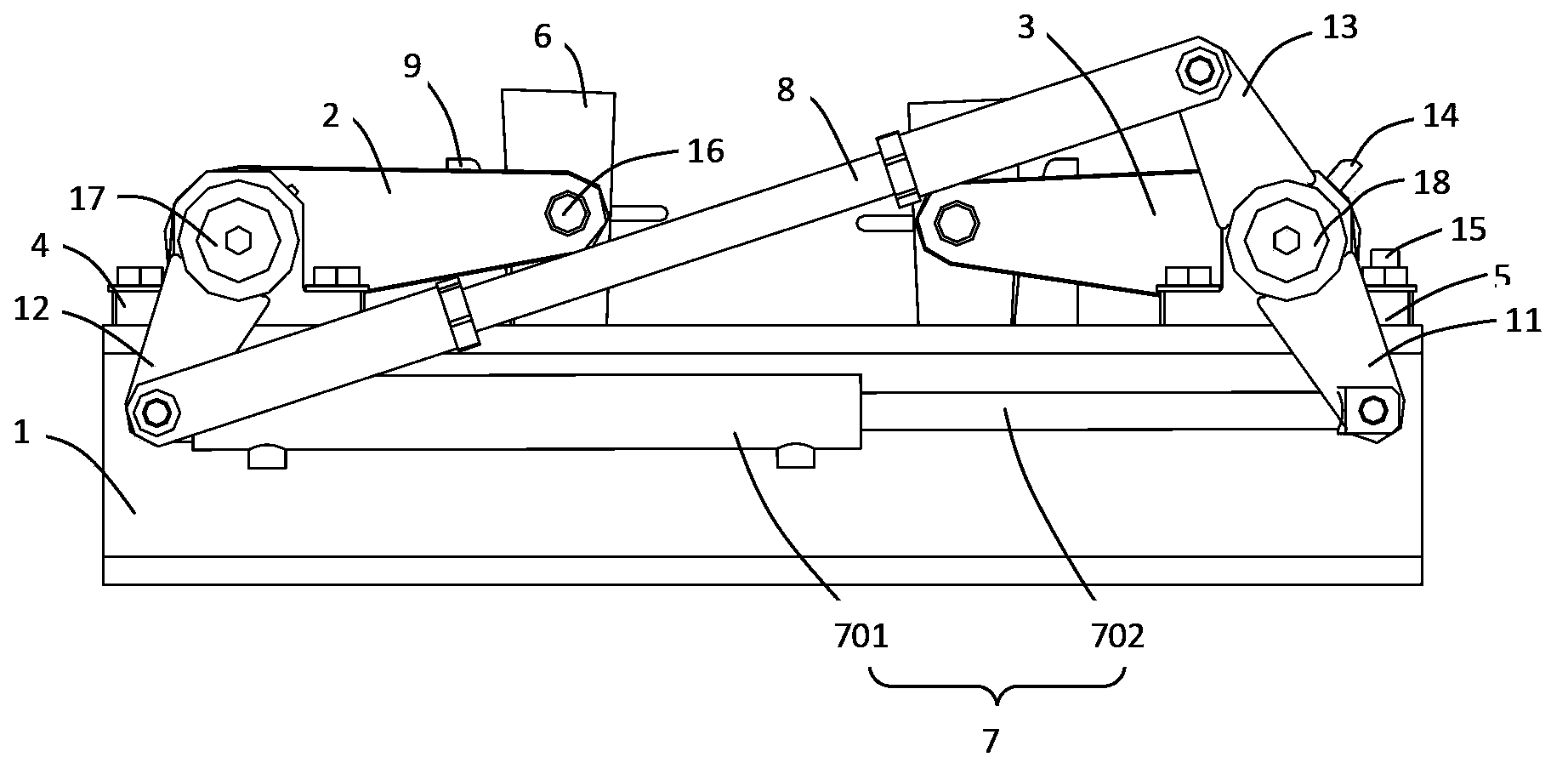

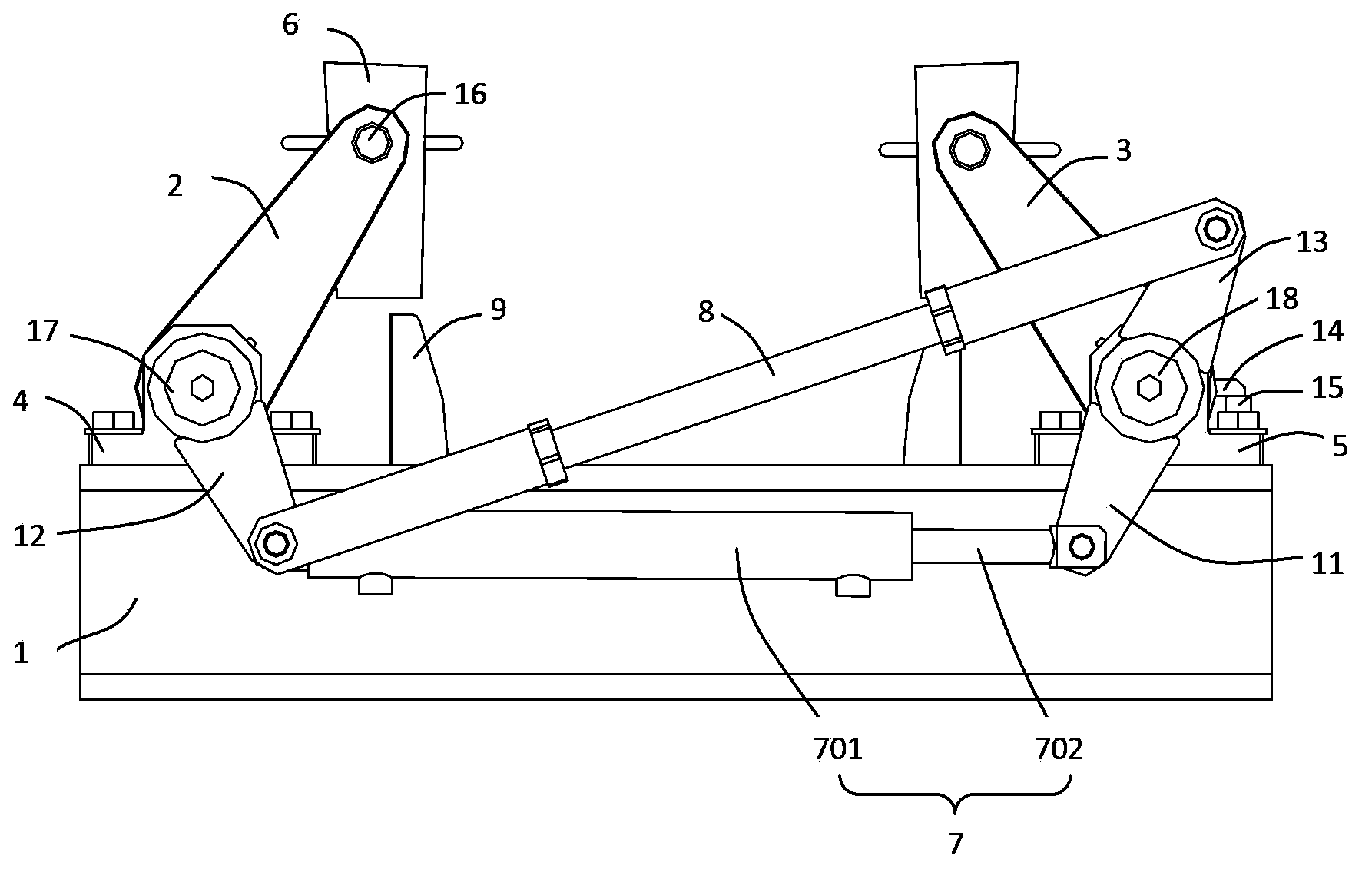

[0016] Such as Figure 1~4 As shown, the core drilling rig holder of the present invention includes a base 1, a left rotating shaft 17, a right rotating shaft 18, a left arm 2 and a right arm 3, and the left rotating shaft 17 and the right rotating shaft 18 pass through a pair of bearings respectively 4 and 5 are installed on the base 1, and one end of the left arm 2 and the right arm 3 is installed on the left shaft 17 and the right shaft 18 respectively, and the left shaft 17 and the right shaft 18 can be mounted on the left bearing 4 and the right side bearing 5 to rotate, thereby driving the left arm 2 and the right arm 3 to rotate, and the other ends of the left arm 2 and the right arm 3 are respectively hinged with the slips 6 for clamping the drill rod. exist Figure 1~4 In the illustrated embodiment of the core drilling rig holder of the present invention, the slip 6 is a two-piece slip, and the two parts are hinged to the left arm 2 and the right arm 3 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com