Shell device for local reactive power compensation

An enclosure and movable installation technology, applied in substation/distribution device enclosure, substation/switchgear cooling/ventilation, substation/switch arrangement details, etc. , to facilitate installation and removal, increase the ability to accommodate electrical components, and speed up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

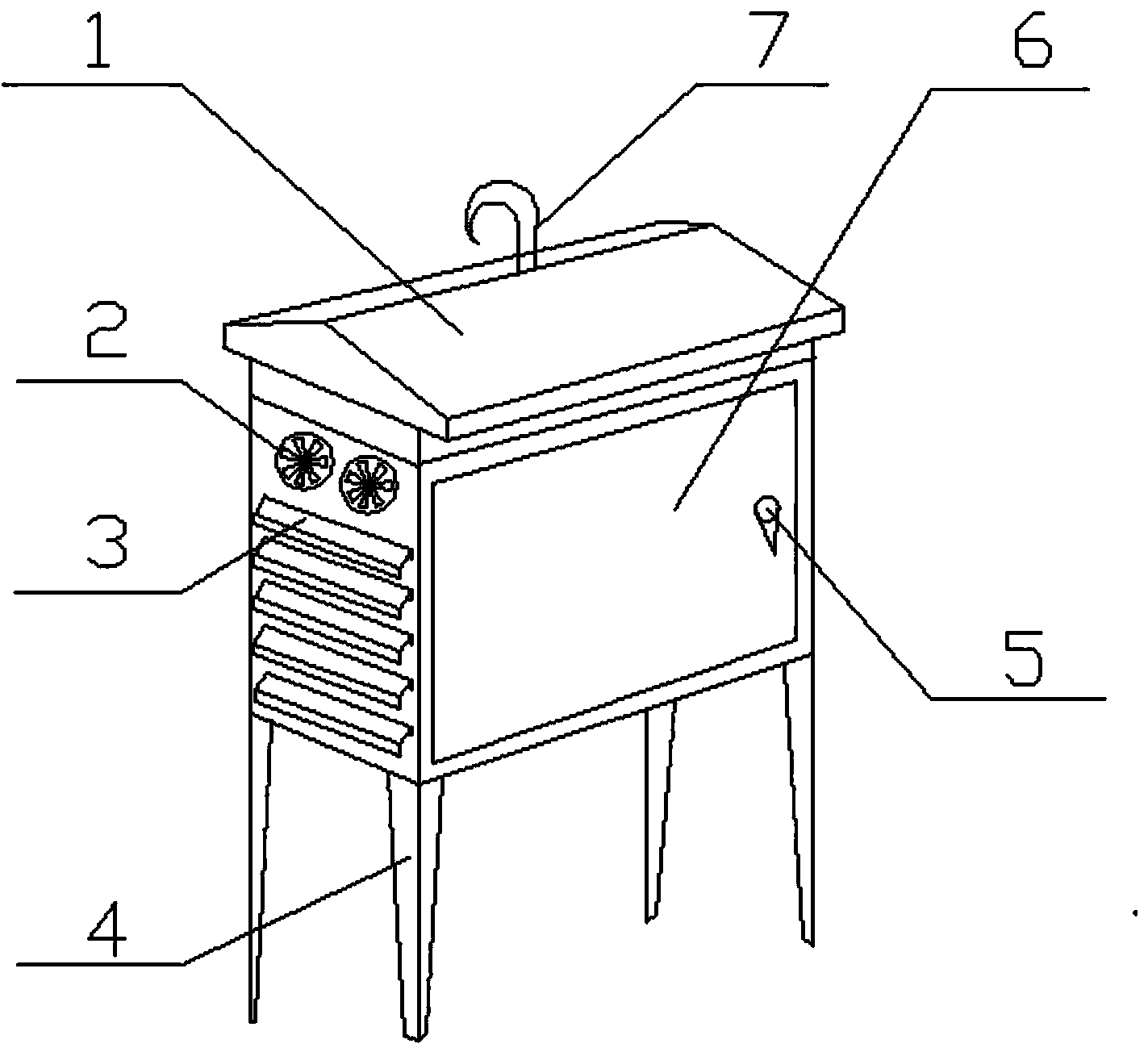

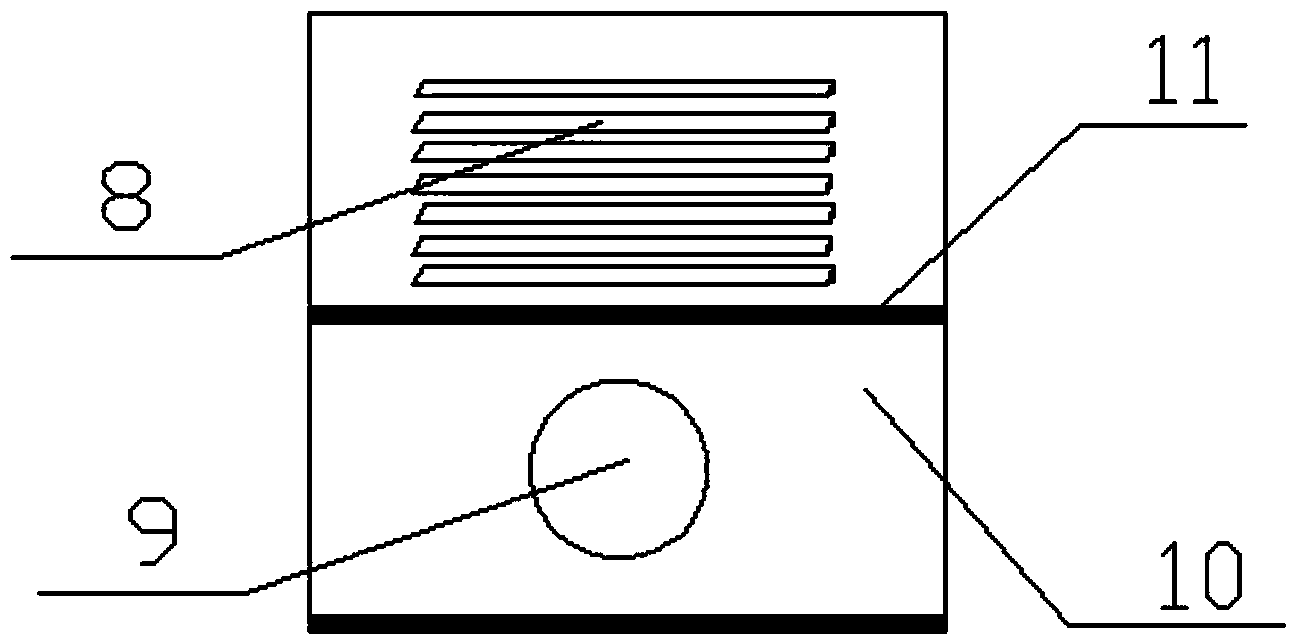

[0042] A shell device specially used for reactive power on-site compensation, made of non-combustible iron or stainless steel, including: a box body and a roof cover; the roof cover is movably installed on the top of the box body, and the box body and the The roof cover forms a hollow chamber for placing reactive in-situ compensation devices;

[0043] The front and rear sides of the casing are respectively provided with a door 6, and the door 6 is provided with a door lock 5, and the door lock 5 can adopt a combination lock or not;

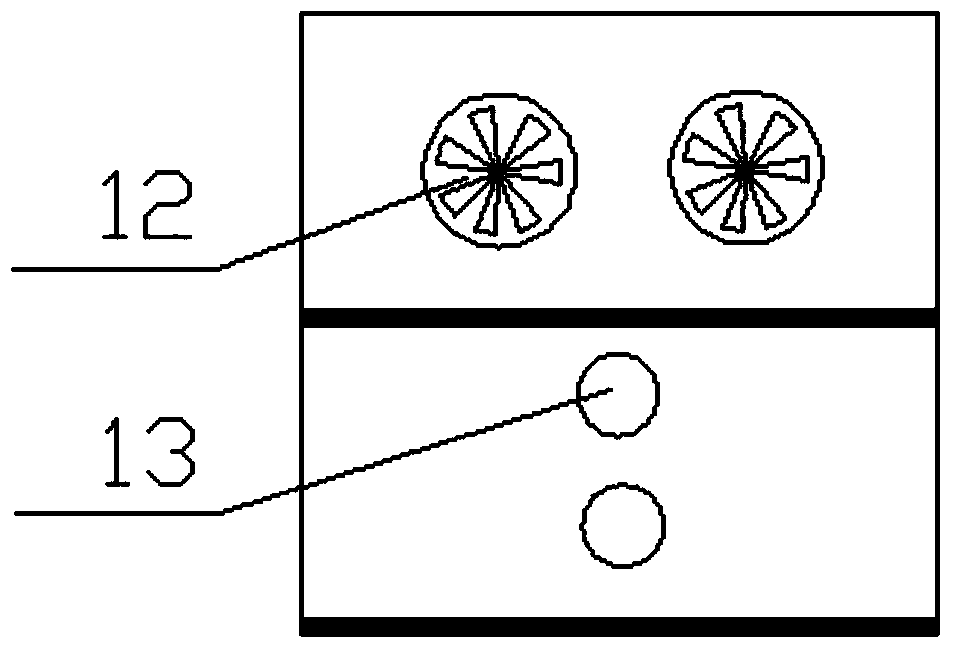

[0044] A heat dissipation mechanism is provided on one side of the box;

[0045] The heat dissipation mechanism includes a first heat dissipation fan 2 arranged in parallel up and down and a plurality of elongated heat dissipation holes 3, for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com