Operation method for replacing strain insulator of 35kV overhead distribution line in live state

A technology for tensile insulators and distribution lines, applied in overhead lines/cable equipment, etc., can solve the problems of increasing unsafe factors, low operation efficiency, and many human resources, and improve the operation level, power supply reliability, and operation efficiency. and safety improvement, economic and social benefits are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

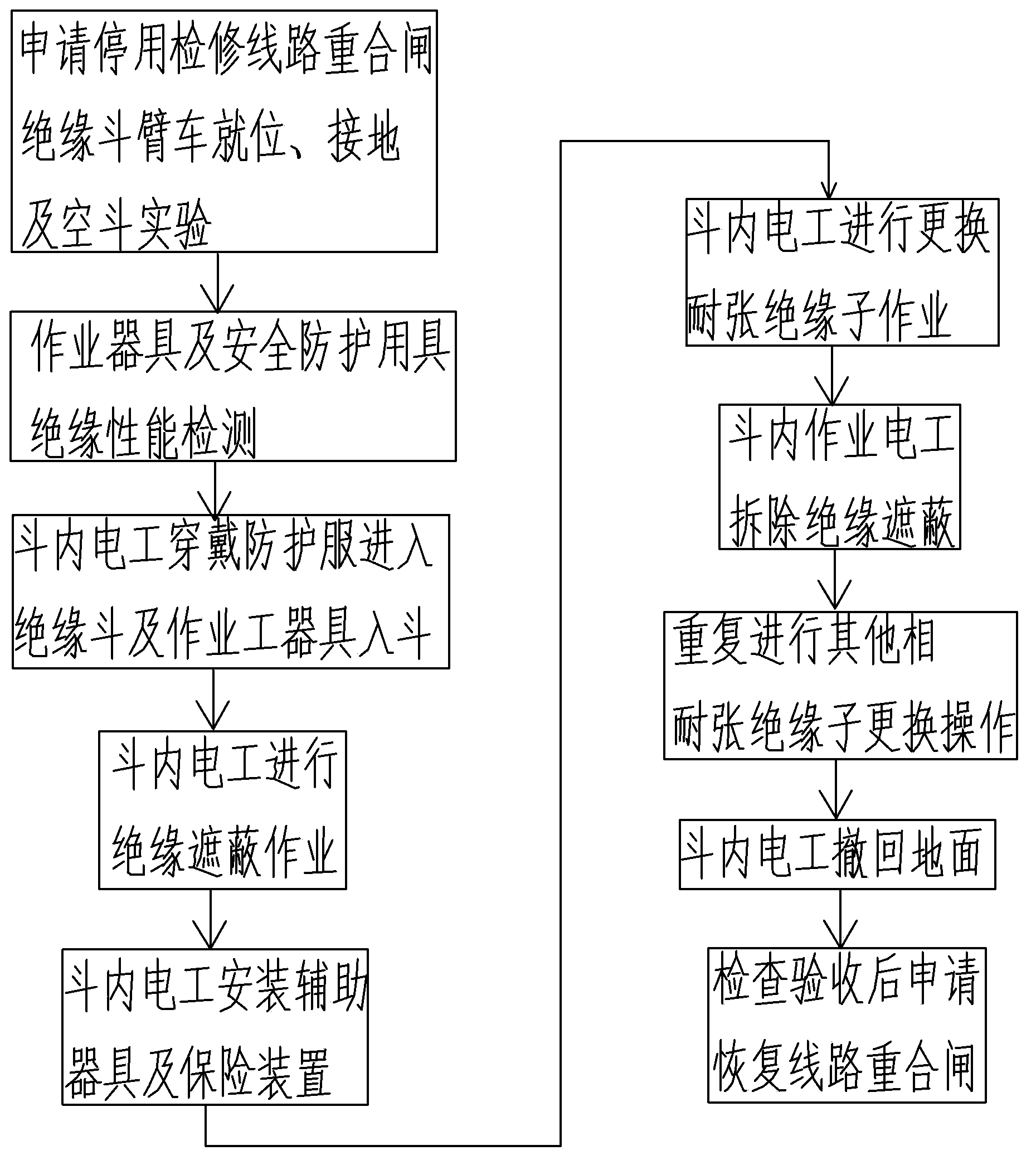

[0020] See figure 1 , the operating method for live replacement of tension insulators on 35kV overhead distribution lines in this embodiment is a method of replacing tension insulators on 35kV overhead distribution lines by using an insulating bucket truck and using intermediate potential insulating gloves.

[0021] The operating personnel include: the person in charge of the operation, one electrician working on the ground and one electrician working inside the insulating bucket.

[0022] Operating tools mainly include: wire shielding cover, insulator cover, insulating blanket, cross-arm shielding cover and insulating rope, airfoil clamps, and safety devices.

[0023] Safety protective equipment mainly includes: a full set of protective equipment worn by working electricians: such as insulating clothing, insulating boots, insulating gloves and insulating helmets.

[0024] Corresponding preparations are required before the operation. The preparation work mainly includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com