Overlying adhesive processing method for motor rotor iron core

A technology of rotor core and processing method, which is applied in the direction of manufacturing stator/rotor body, etc., to achieve the effect of good electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

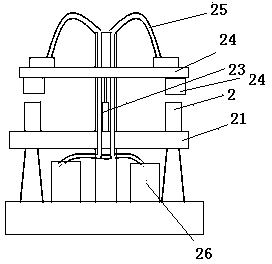

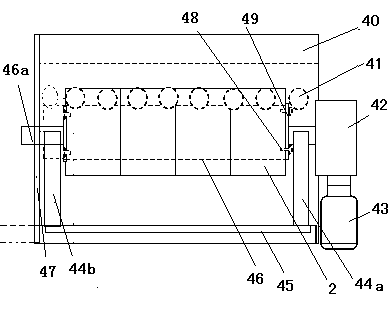

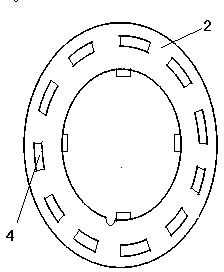

[0010] Refer to the following figure 1 , figure 2 , image 3 Describe the specific implementation of the present invention, in the figure, 1: core hole, 2: iron core, 4: slot hole, 21: laminating table, 22: hydraulic head, 23: cylinder, 24: hydraulic plate, 25: Hydraulic pipe, 26: Hydraulic device, 31: Center hole shovel, 32a: Slot hole shovel head 1, 33: Knife holder, 34: Fixing bolt, 40: Shot blasting machine, 41: Shot blasting gun mouth, 42: reducer, 43: motor, 44a: right carriage support, 44b: left carriage support, 45: carriage base, 46: axle frame, 47: door, 48: bolt, 49: iron cover.

[0011] After the gluing machine applies glue, the unloader automatically superimposes the rotor silicon steel sheet on the iron core frame. The silicon steel sheet has not yet solidified and cannot be directly transported. It needs to be transported together with the iron core frame to prevent the shape of the iron core from being deformed during subsequent processing. . After stackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com