Circuit board automatic smoothing machine and smoothing method

A circuit board, automatic technology, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as unsatisfactory smoothing effect, poor OLB recognition, increased production costs, etc., to achieve good smoothing effect and reduce throwing rate. , Conducive to the effect of fitting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are the best examples of the automatic circuit board smoothing machine and its smoothing method according to the present invention, which do not limit the protection scope of the present invention.

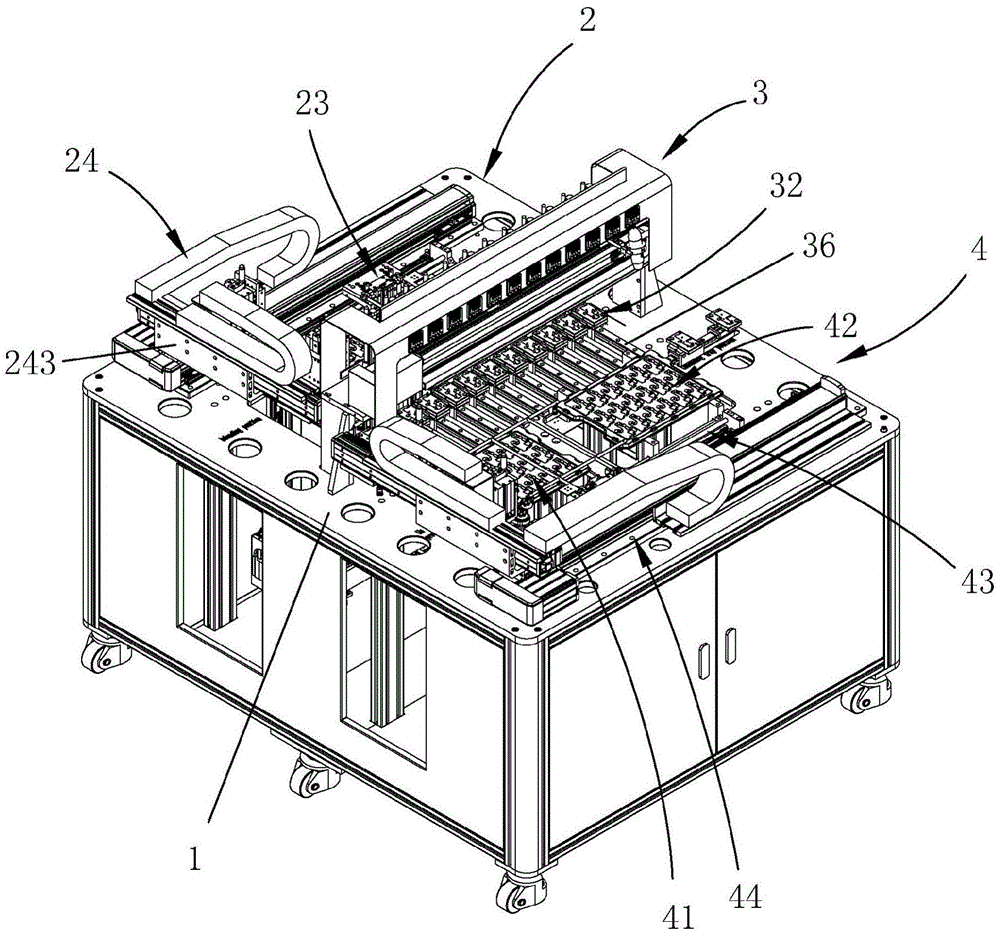

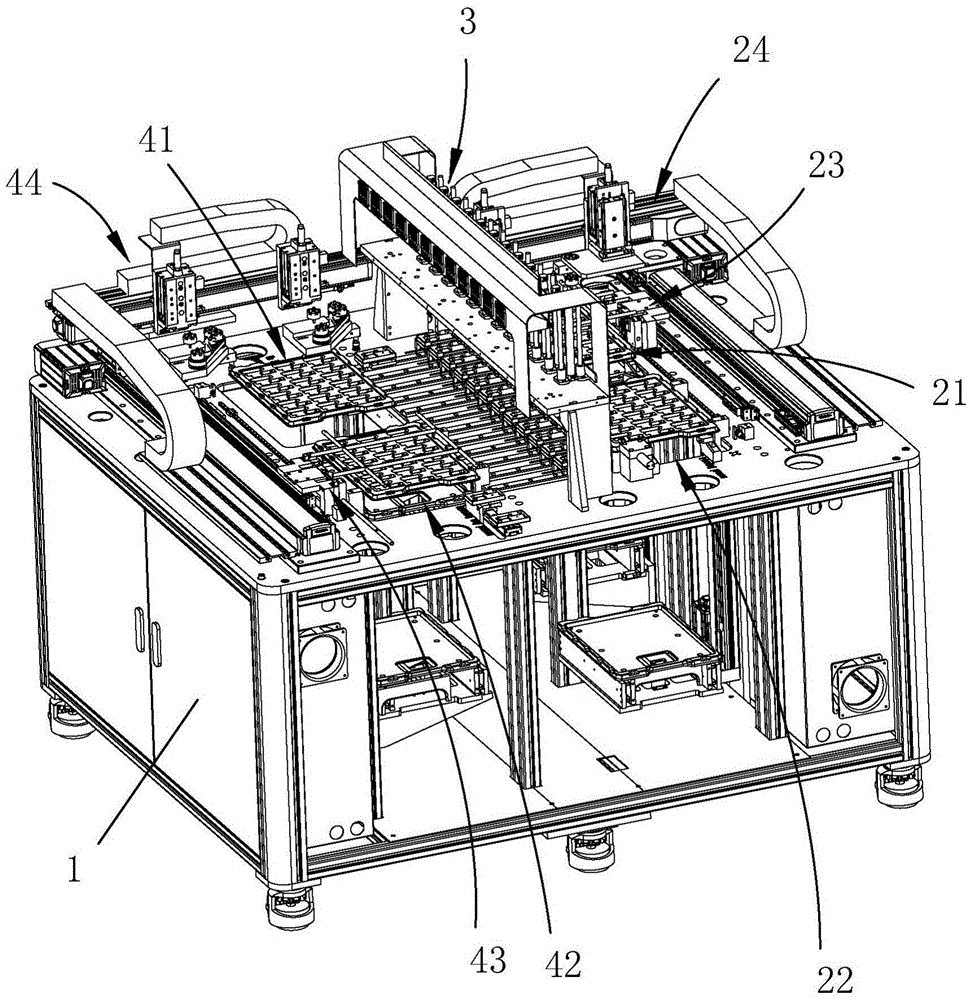

[0029] Please refer to figure 1 and figure 2 , the figure shows an automatic circuit board smoothing machine, including a frame table 1, which is sequentially provided with a feeding mechanism 2, a hot-press smoothing mechanism 3 and a discharging mechanism 4 controlled by a control system.

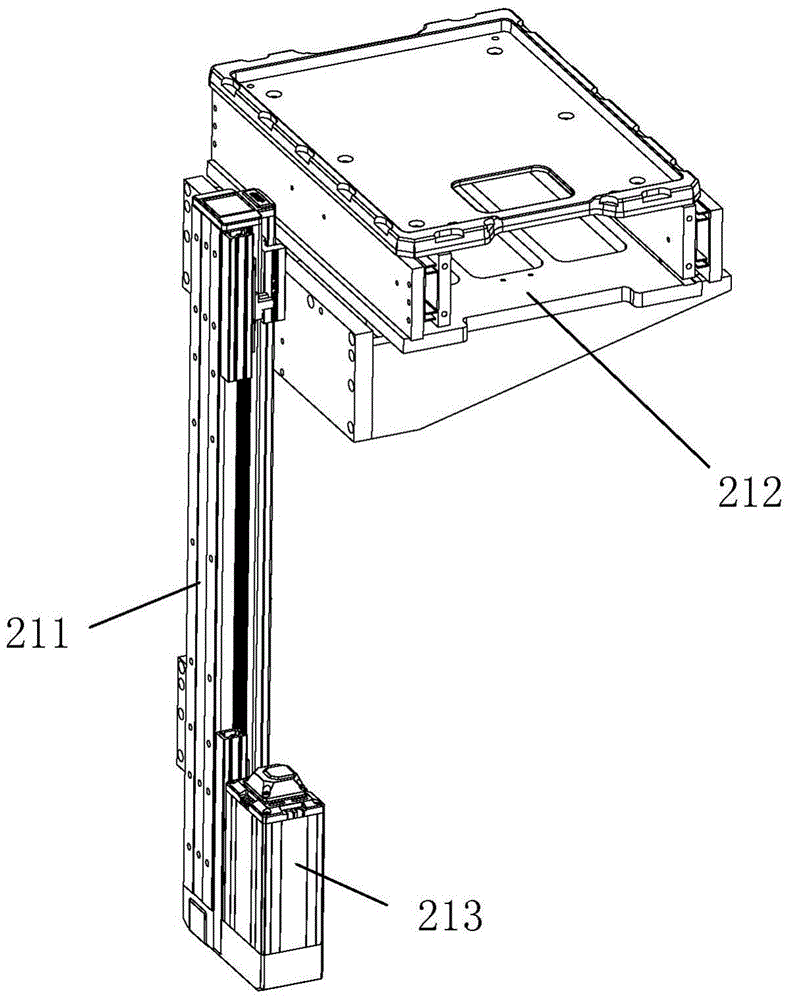

[0030] Such as figure 1 and figure 2 As shown, the feeding mechanism 2 includes a first tray lifter 21 that can supply a tray to be smoothed out, a second tray lifter 22 for unloading an empty tray, and a second tray lifter 22 for unloading the first tray. The empty tray on the lifting device 21 is transferred to the first tray transfer device 23 of the second tray lifting device 22 and is used to suck the circuit board to be smoothed placed on the tray of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com