Method for matching color and appearance of coatings containing effect pigments

A color and formula technology, applied in coating, color matching, color measuring devices, etc., can solve problems such as difficult matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0189] The coating of a 2002 Jeep Cherokee (target coating 1) was measured. Based on the vehicle's make, model year 2002 and its color code PDR, obtained from the ColorNet® automotive refinishing color system from E.I. du Pont de Nemours and Company, Wilmington, DE, USA, under the respective trademarks or registered trademarks (Table 1) A number of preliminary matching formulations (F1-F7) were retrieved.

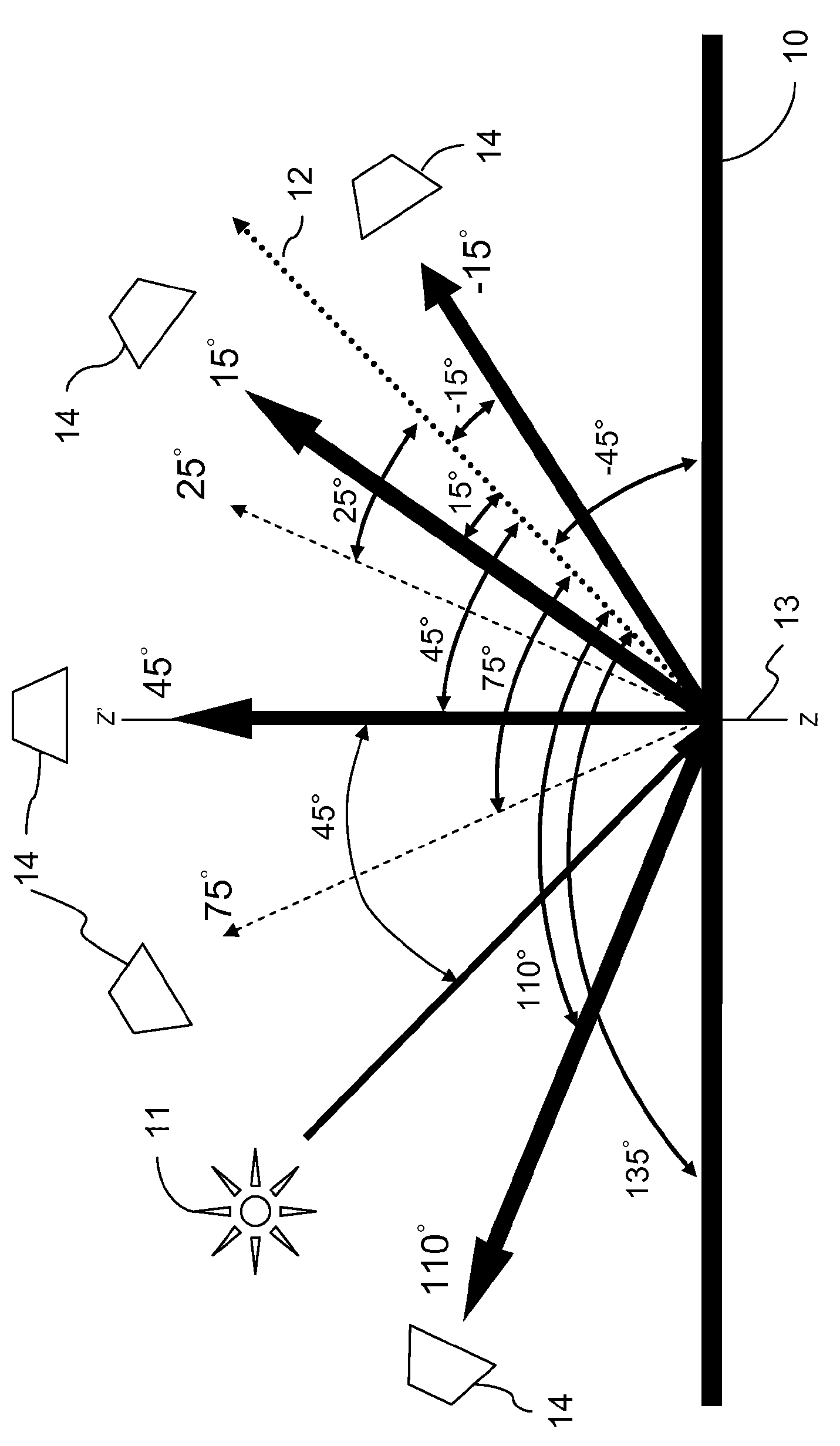

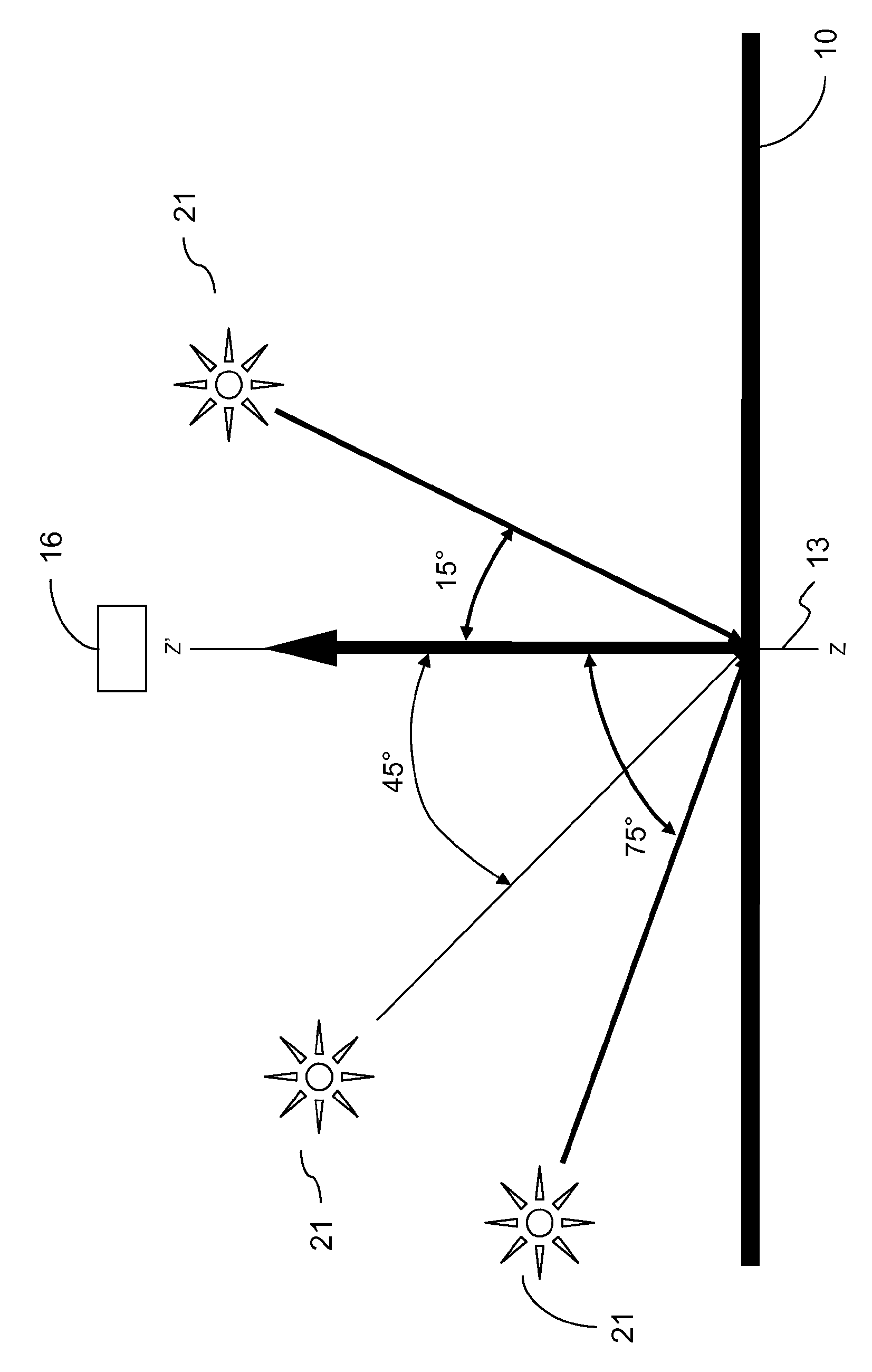

[0190] The color data and gloss values were measured using BYK-mac obtained from BYK-Gardner USA, Maryland, USA. The flop value of the vehicle coating is generated based on color data measured at 3 viewing angles selected from 15°, 45° and 110°. Gloss data based on figure 2 Images captured in the normal direction are shown with an illumination angle selected from 15° and 45°.

[0191] The flop properties of the matching formulations are stored in the ColorNet™ system's color database and have data compatible across the measured vehicle's viewing angle. The gloss prop...

Embodiment 2

[0204] The coating of a 2003 Ford Explorer (target coating 2) was measured. Based on the vehicle's make, model year 2003 and its color code JP, a number of preliminary matching formulas (F8-F13) were retrieved from the ColorNet™ automotive refinish color system (Table 3). This preliminary matching formula was analyzed as described above and ranked as shown in Table 4. Recipes in category group 2 were adjusted to produce subsequent matching recipes with subsequent CDIs (sub-CDIs).

[0205] Table 3. flop and gloss data. the

[0206] recipe number initial CDI Sub-CDI type Different colors S g 15 S g 45 ΔF ΔS g 15 ΔS g 45 Target Coat 2 - - - 9.80 7.62 7.55 - - - F8 - - 4 11.30 5.88 4.82 0.15 -1.74 -2.73 F9 2.70 1.40 2 9.28 7.29 6.46 -0.05 -0.33 -1.09 F10 - - 3 10.68 6.56 5.58 0.09 -1.06 -1.97 F11 3.20 1.80 2 10.24 7.37 6.13 0.05 -0.25 -1.42 F12 2.40 1.70 2 9.33 7.13 6....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap