Support arm assembly, vehicle suspension system and vehicle using the suspension system

A technology of vehicle suspension and support arm, which is applied in the direction of suspension, elastic suspension, vehicle components, etc., which can solve the problems of damage to vehicle ride comfort, short service life, irregular movement of axles, etc., and avoid irregular movement , Improve connection reliability and reduce the effect of unsprung mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

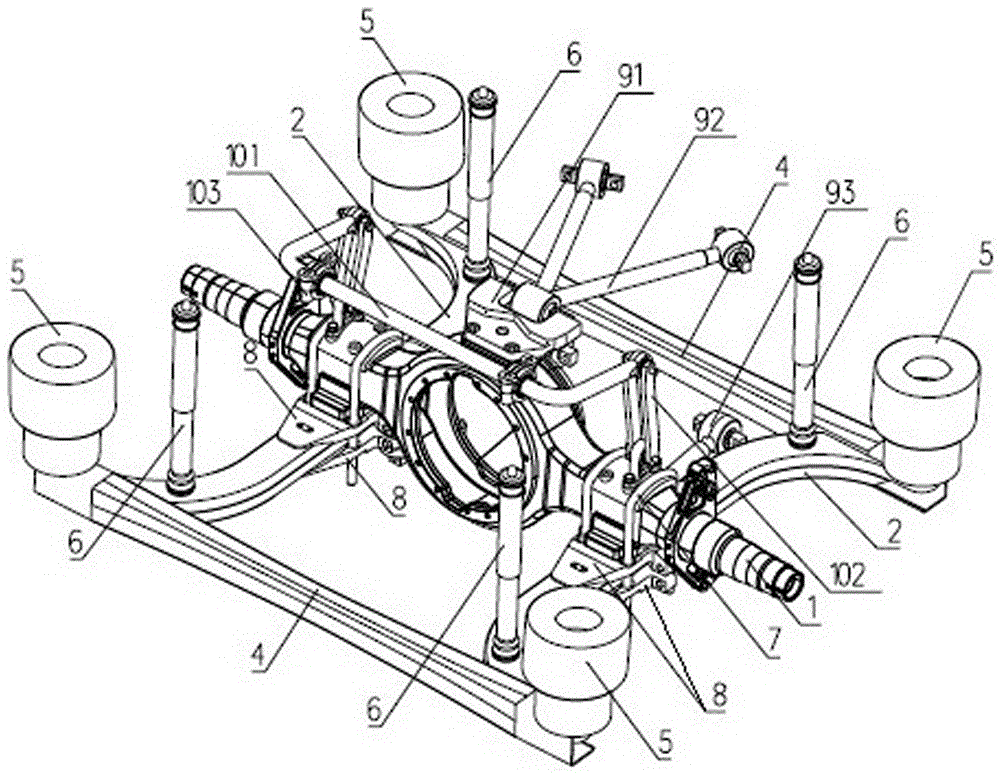

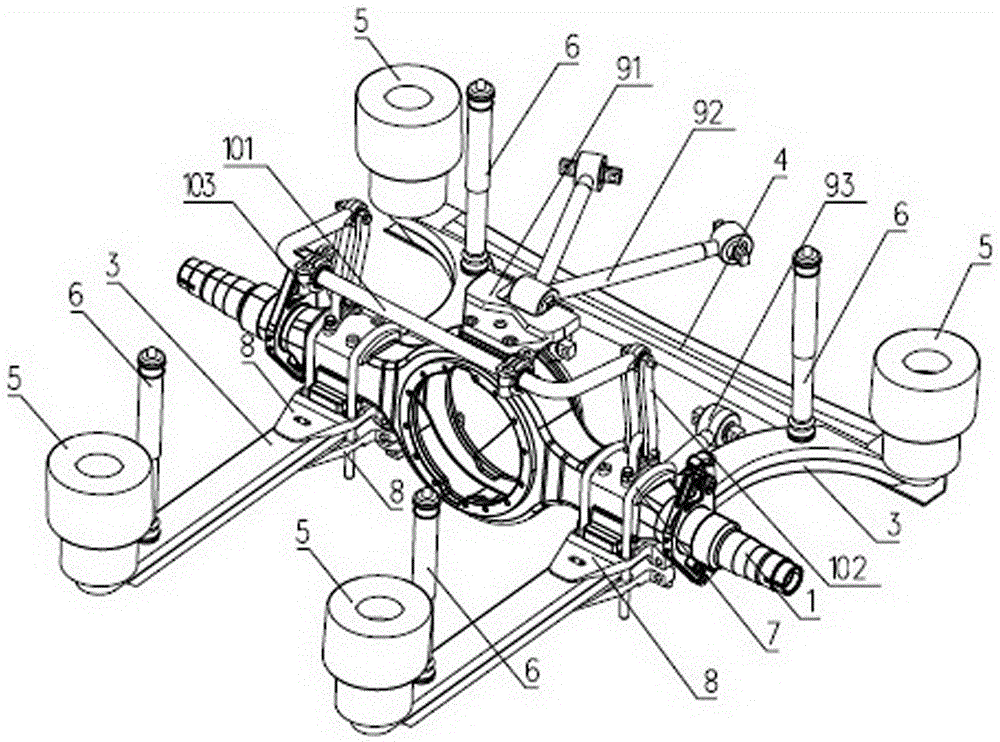

[0019] Embodiments of the vehicle suspension system in the present invention are as figure 1 As shown, it is a composite suspension system for the rear axle of a vehicle, including two C-shaped brackets 2 corresponding to the two ends of the integral vehicle axle 1, and a shock absorber set on the C-shaped bracket 2 6 and air spring 5.

[0020] The two C-shaped support arms 2 are respectively a left support arm and a right support arm. Both the left support arm and the right support arm are C-shaped and the openings of the left support arm and the right support arm face away from each other. The integral axle 1 spans between the middle positions of the two C-shaped support arms 2 in the front-rear direction, and the two ends are fixed with the two C-shaped support arms 2 by U-shaped bolts 7 . The integral frame is provided with a thrust rod assembly and a stabilizer bar 101 assembly. The thrust rod assembly includes a V-shaped thrust rod 92 and two parallel straight thrust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com