Rod tobacco filling device and method for filling tobacco

A technology for adding devices and sticks of cigarettes, which is applied in the field of cigarette packaging, can solve problems such as time-consuming and laborious, and hidden dangers to the safety of operators, and achieve the effects of avoiding centralized storage, ensuring timeliness, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

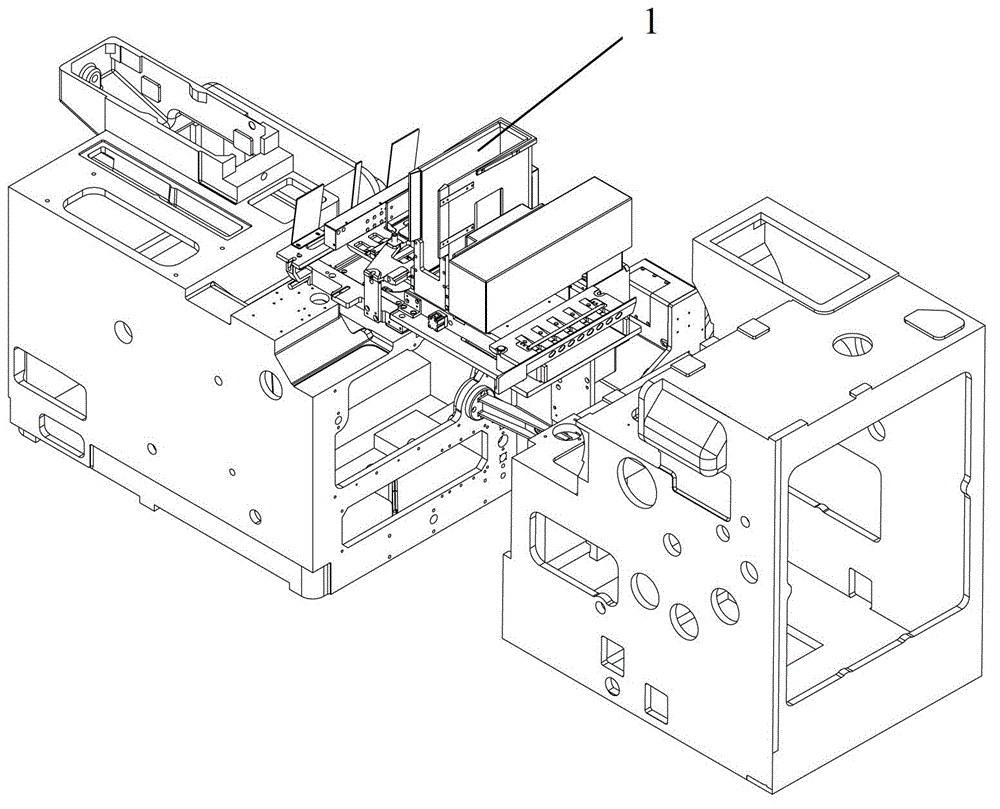

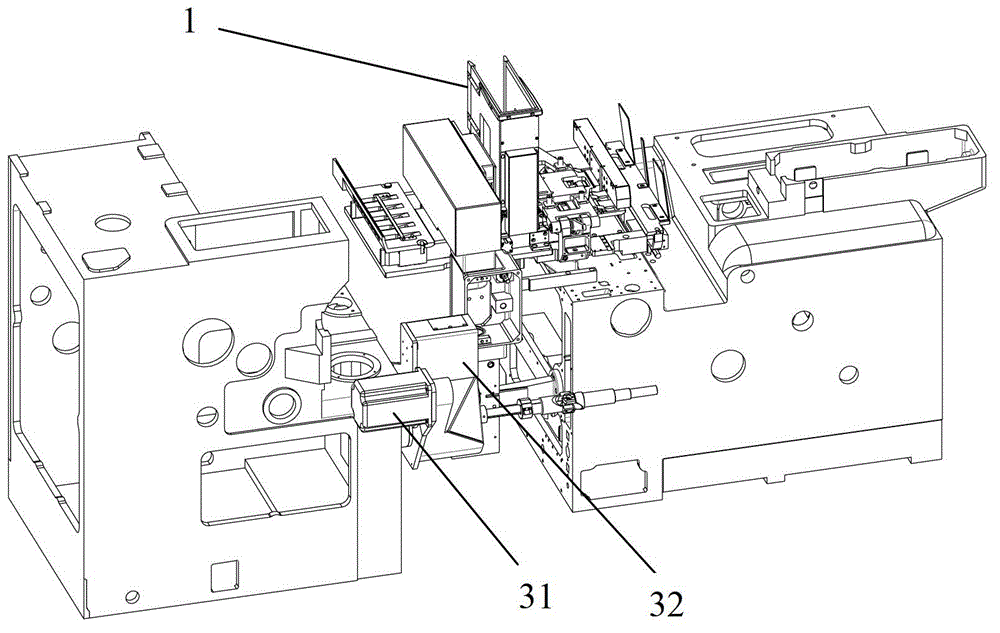

[0035] Such as figure 1 and figure 2 As shown, the rod filling device includes a smoke storage device 1, a rod propelling device 2, a power device and an electric control device.

[0036] The electric control device can be selected from other industrial control systems such as PLC programmable controller or single chip microcomputer. This embodiment uses a PLC programmable controller, which is easy to use and simple to program. It uses programming languages such as concise ladder diagrams, logic diagrams, or statement lists without requiring computer knowledge. Therefore, the system development cycle is short and on-site debugging is easy. In addition, the program can be modified online, and the control scheme can be changed without dismantling the hardware.

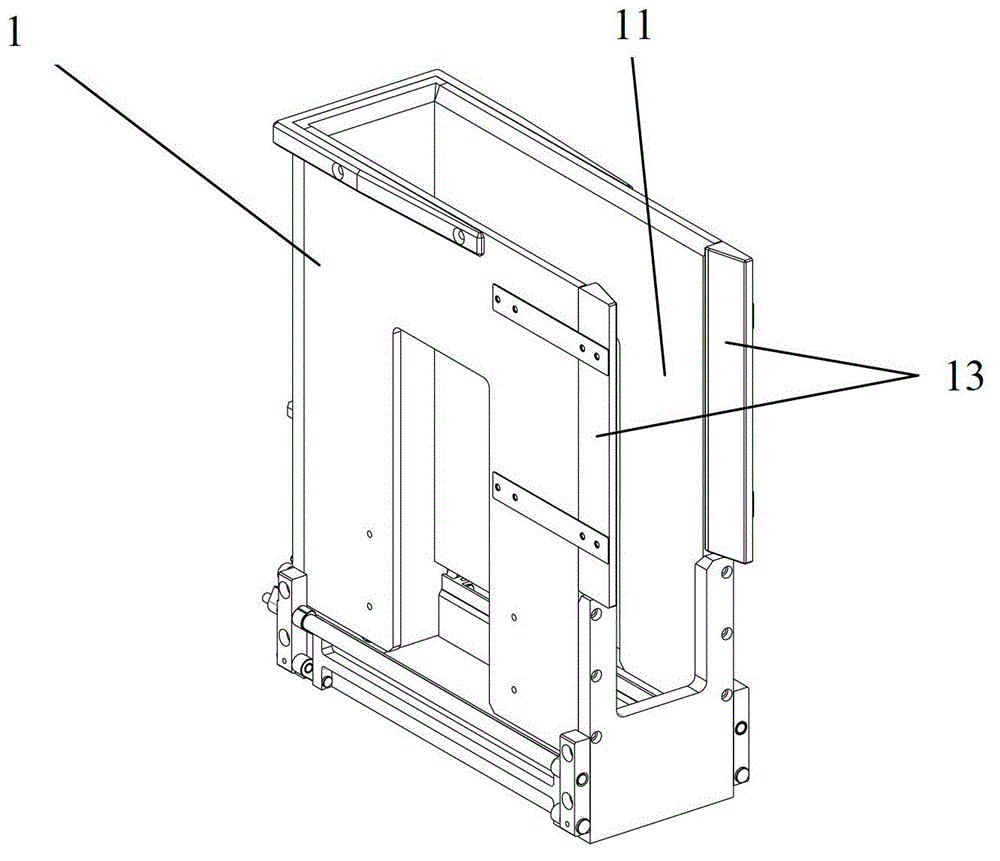

[0037] Such as figure 1 and figure 2 As shown, the cigarette storage device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com